Onion-shaped fullerene clad metal palladium core shell structure nano-particle and preparation method thereof

A technology of onion-like fullerenes and nanoparticles, which can be used in metal processing equipment, nanotechnology, transportation and packaging, and can solve the problems of expensive preparation costs and poor crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

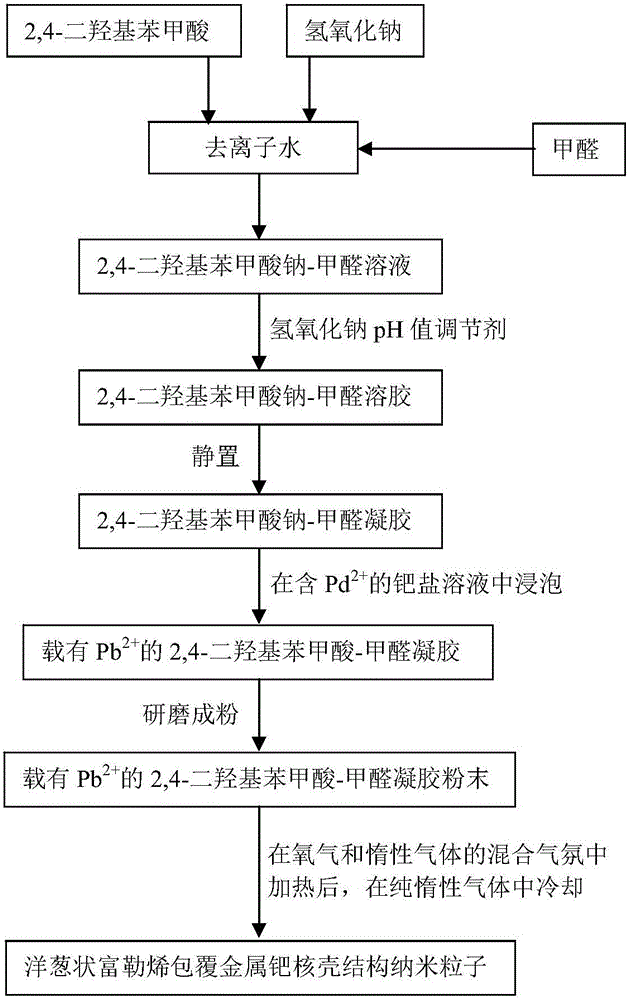

[0048] The method for preparing onion-like fullerene-coated metal palladium core-shell structure nanoparticles of the present invention comprises the following steps:

[0049] Step 1: Preparation of Sodium 2,4-Dihydroxybenzoate-Formaldehyde Sol

[0050] Dissolve 2,4-dihydroxybenzoic acid and sodium hydroxide in deionized water to prepare a solution, then add formaldehyde and stir to form a 2,4-dihydroxybenzoic acid sodium-formaldehyde solution; then add sodium hydroxide to adjust the pH value The pH value of 2,4-dihydroxybenzoic acid sodium-formaldehyde solution until it becomes 2,4-dihydroxybenzoic acid sodium-formaldehyde sol.

[0051] Preferably, 2,4-dihydroxybenzoic acid, sodium hydroxide and formaldehyde are formulated into 2,4-dihydroxybenzoic acid sodium-formaldehyde solution according to the molar ratio of 1:1:4, and the sodium hydroxide pH value regulator Adjust the pH of the solution to 7-9, then dilute with deionized water.

[0052] Step 2: Preparation of sodium 2...

Embodiment 1

[0063] According to the molar ratio of 2,4-dihydroxybenzoic acid, sodium hydroxide and formaldehyde at a ratio of 1:1:4, a 2,4-dihydroxybenzoic acid sodium-formaldehyde gel with a volume of 100 mL and a density of 0.1 g / mL was prepared. Wherein, the density of 2,4-sodium dihydroxybenzoate-formaldehyde gel is obtained by dividing the mass of sodium 2,4-dihydroxybenzoate plus formaldehyde by the volume of sodium 2,4-dihydroxybenzoate-formaldehyde solution.

[0064] Dissolve 5.2g of 2,4-dihydroxybenzoic acid and 1.35g of sodium hydroxide in deionized water first. At this time, the volume of deionized water used should not exceed 70mL to form a solution. 2,4-dihydroxybenzoic acid reacts with sodium hydroxide to generate sodium 2,4-dihydroxybenzoate, thereby obtaining a sodium 2,4-dihydroxybenzoate solution.

[0065] Add 10mL of formaldehyde solution with a concentration of about 38wt% into the sodium 2,4-dihydroxybenzoate solution, and stir evenly to form a light yellow transparen...

Embodiment 2

[0070] Prepare 2,4-dihydroxybenzoic acid sodium-formaldehyde gel with a volume of 100 mL and a density of 0.3 g / mL according to the molar ratio of 2,4-dihydroxybenzoic acid, sodium hydroxide and formaldehyde at a ratio of 1:1:4. Wherein, the density of 2,4-sodium dihydroxybenzoate-formaldehyde gel is obtained by dividing the mass of sodium 2,4-dihydroxybenzoate plus formaldehyde by the volume of sodium 2,4-dihydroxybenzoate-formaldehyde solution.

[0071] Dissolve 15.6g of 2,4-dihydroxybenzoic acid and 4.06g of sodium hydroxide in deionized water first. At this time, the volume of deionized water used should not exceed 50mL to form a solution. 2,4-dihydroxybenzoic acid reacts with sodium hydroxide to generate sodium 2,4-dihydroxybenzoate, thereby obtaining a sodium 2,4-dihydroxybenzoate solution.

[0072] Add 32mL of formaldehyde solution with a concentration of about 38wt% into the sodium 2,4-dihydroxybenzoate solution, and stir evenly to form a light yellow transparent liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com