Ndfeb permanent magnet material with high magnetic energy product and high coercivity and manufacturing method thereof

A high coercive force and permanent magnet material technology, which is applied in the field of NdFeB permanent magnet materials with high magnetic energy product and high coercive force and its manufacturing field, can solve the problem of affecting the magnetic coupling effect of the liquid phase, high re-investment costs, and reduced Coercive force improvement effect and other issues, to achieve the effect of improving uniform deposition and transportation, reducing auxiliary supporting costs, and reducing local loss of magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

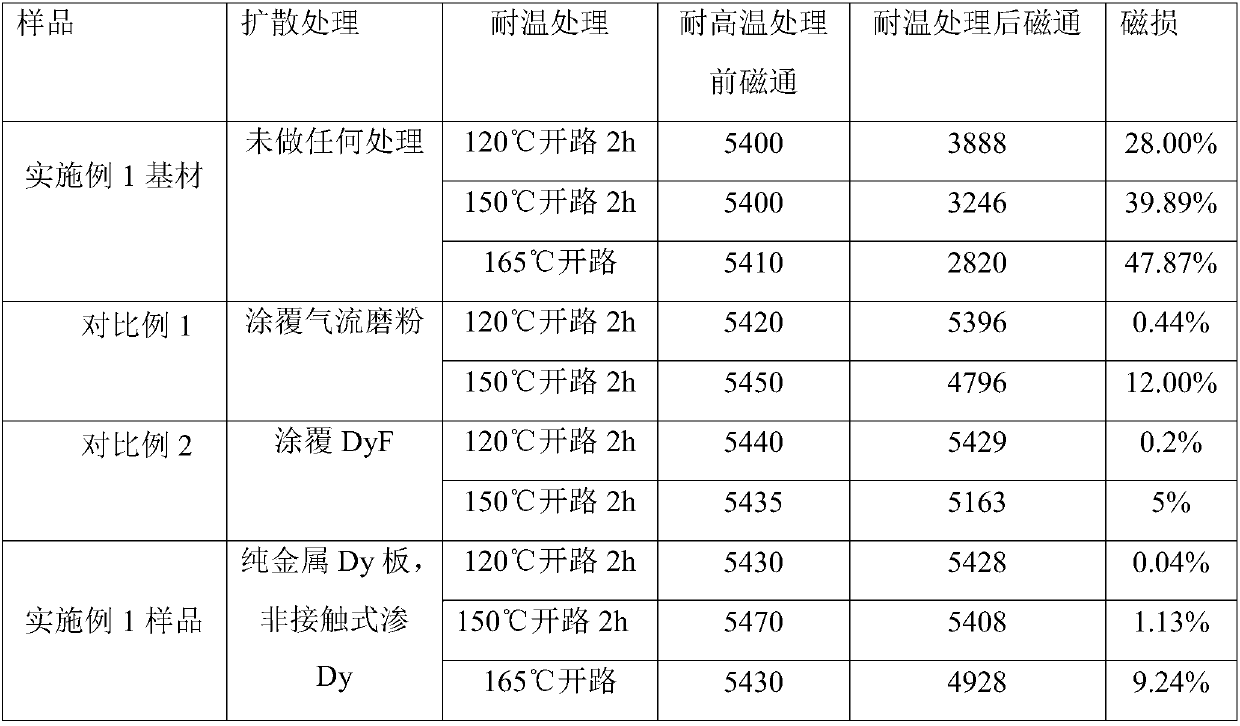

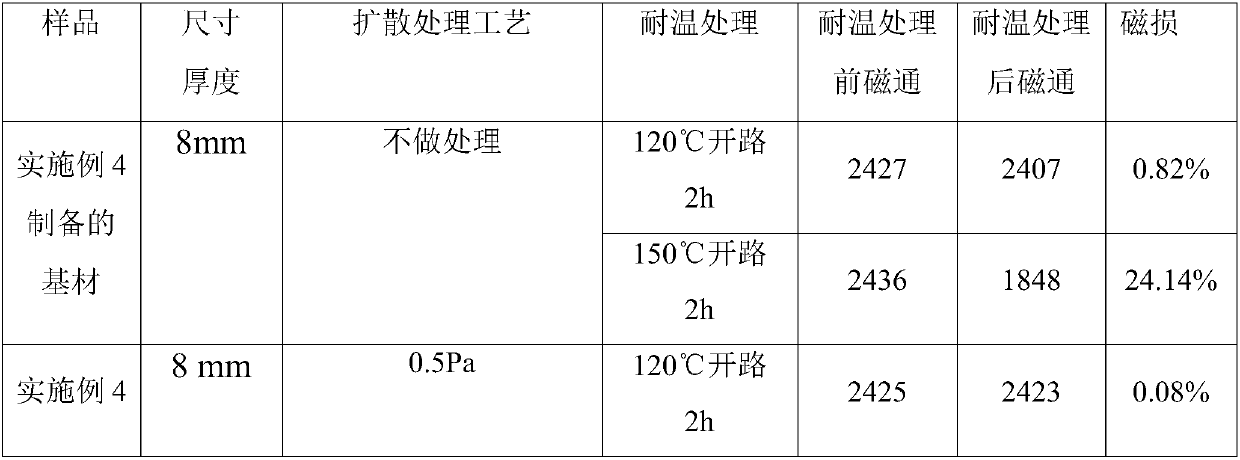

Embodiment 1

[0031] Matrix preparation: the rest of the composition is Nd28.3Tb2.5B0.96Cu0.05Co0.5Zr0.13Ga0.25Fe, using the flake technology, the average thickness of the flakes is 0.3mm at the pouring temperature of 1400 ℃, and the flakes are prepared by the hydrogen crushing process Hydrogen crushed powder with a hydrogen content of 1200ppm, added with 0.06wt% antioxidant and 0.1wt% lubricant and mixed for 60 minutes, prepared a fine powder with an average particle size of 3.1±0.15μm by jet mill, and then under the condition of 1.8T magnetic field Carry out orientation magnetization, and sinter at 1073°C for 5h, then keep at 900°C for 2h for the first step of aging, and then keep at 500°C for 5h for the second step of aging, prepare the blank, and then add the blank and process it into 20*18.8* The substrate sample is 1.8mm, and the surface roughness is Ra: 0.4μm, and the oxygen content in the center of the magnet is 1200ppm. Such as figure 1 As shown in Figure a: after sintering, there...

Embodiment 2

[0036] The blank prepared in Example 1 is processed into a sample of 20*18.8*16mm, and the surface roughness is Ra: 5 μm, and the vacuum degree is 3.5*10 -3 Pa, the temperature is 650°C for 5 hours of diffusion, after completion, the vacuum degree is 3.5*10 -3 Pa, the temperature is 100 ℃ diffusion 5h.

[0037] Then, the diffusion process was used for 5 cycles to prepare the required material of Example 2. Others are the same as embodiment 1.

Embodiment 3

[0039] The blank prepared in Example 1 was processed into a sample of 20*18.8*1mm, and the surface roughness was Ra: 0.2μm, and the vacuum degree was 0.5Pa, and the temperature was 950°C for 2 hours. After completion, carry out The vacuum degree is 0.5Pa, and the temperature is 500℃ for 5h.

[0040] Then, the diffusion process was used and circulated 3 times to prepare the required material of Example 3, and the others were the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rough surface | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com