A kind of hierarchical porous supported nickel-based catalyst, preparation method and application

A nickel-based catalyst, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as easy sintering, deactivation, carbon deposition, etc. effect, the effect of increasing diffusion and mass transfer rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation and Characterization of Catalyst Samples CAT-1~CAT-11 of Embodiment 1

[0048] Take a certain amount of nickel salt and dissolve it in 10ml of ethanol to make a solution, add 5g of hierarchical porous alumina, ultrasonic impregnation for a period of time, filter to remove the solvent and excess unabsorbed nickel salt. The aluminum oxide adsorbed with nickel ions was vacuum-dried at 80° C. for 8 hours, calcined in an air atmosphere, and finally reduced with hydrogen to obtain the hierarchically porous supported nickel-based catalyst.

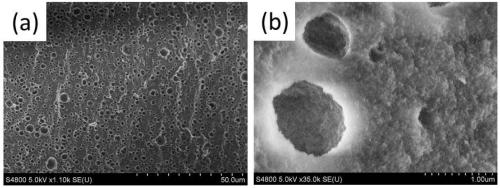

[0049] The nickel content on the hierarchically porous supported nickel-based catalyst was determined by ICP. The particle size range of nickel particles on the hierarchical porous supported nickel-based catalyst was observed by transmission scanning electron microscope.

[0050] See Table 1 for the relationship between the sample number and specific experimental parameters, the mass percentage of nickel element in the hierarc...

Embodiment 2

[0054] Embodiment 2 Catalyst reaction evaluation

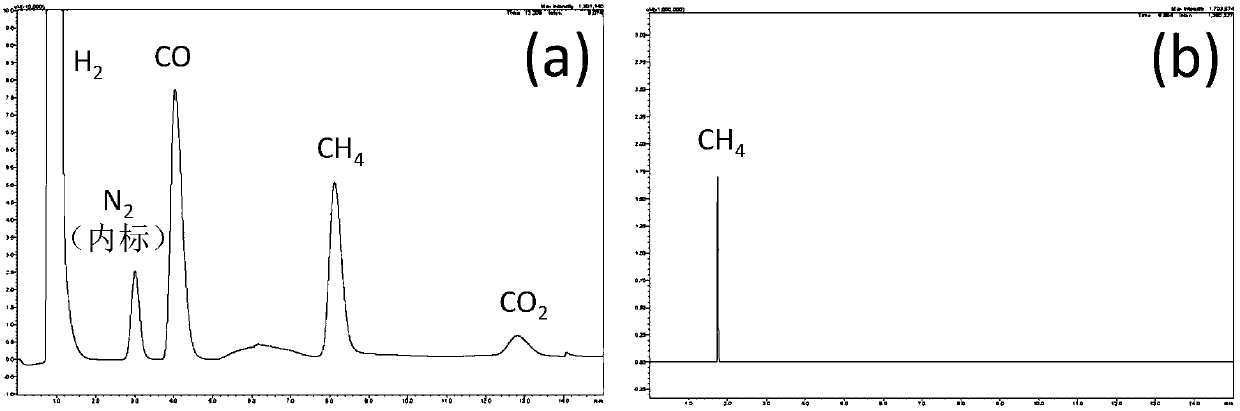

[0055] Take 0.2g of the catalyst sample CAT-1 and place it in a fixed-bed reactor with an inner diameter of 1cm. After hydrogen reduction is performed online, the temperature is adjusted to the reaction temperature. switch gas to CO 2 and CH 4 Mixed gas, N 2 is the internal standard. After the reaction, the gas is cooled and enters the gas chromatograph to detect the concentration of each substance, and calculate the CO 2 and CH 4 conversion rate.

[0056] Reaction conditions and CO 2 and CH 4 The relationship between the conversion rate is shown in Table 2.

[0057] When the reaction condition is A, the chromatographic detection result of the reaction tail gas is as follows figure 2 shown. It can be seen from the figure that the multi-level porous supported nickel-based catalyst provided by the present application has good selectivity, and the product is basically the main components of synthesis gas: hydrogen and ...

Embodiment 3

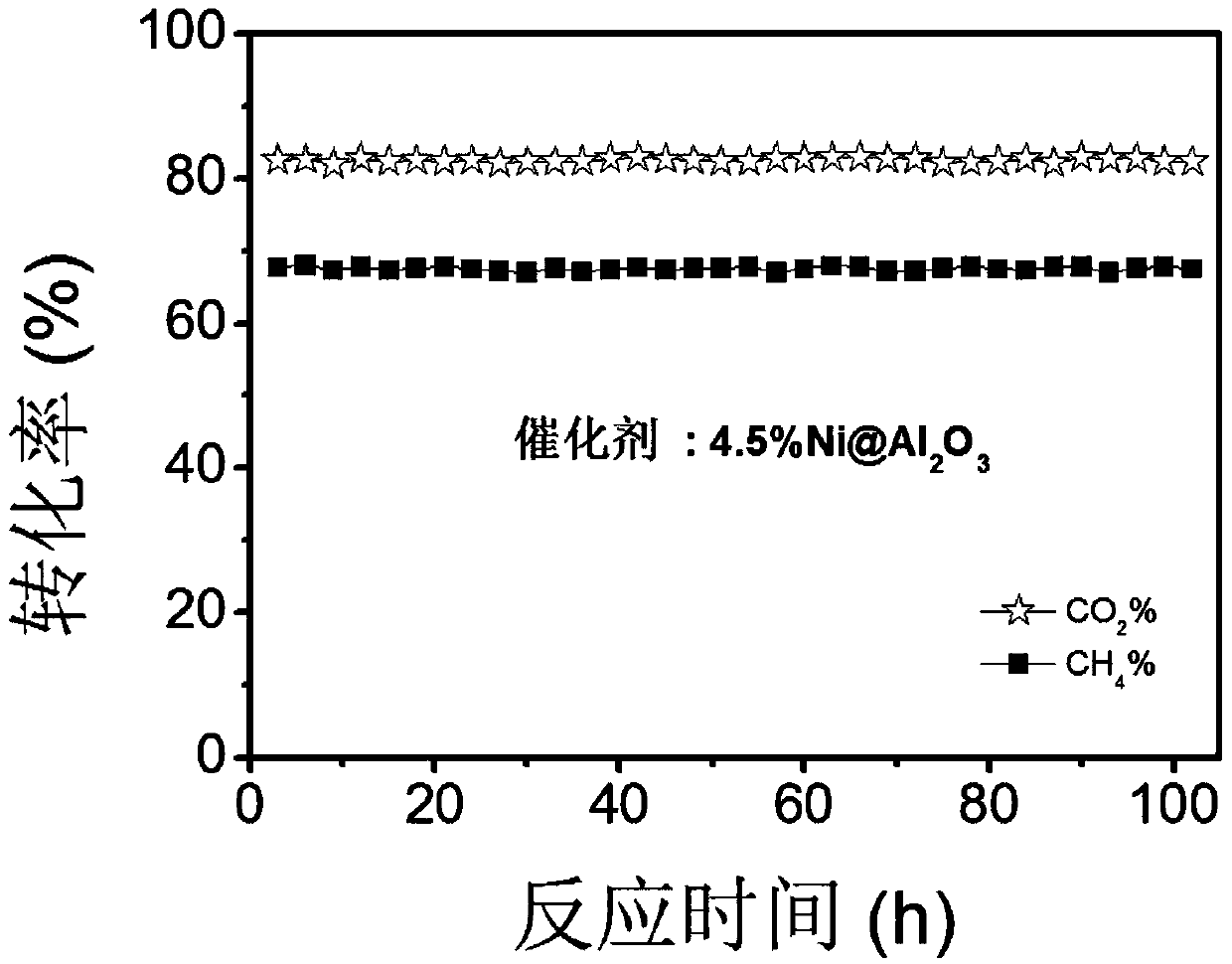

[0066] Embodiment 3 Catalyst stability evaluation

[0067] Get 0.2g catalyst sample CAT-1 and place in the fixed-bed reactor of internal diameter 1cm, under the reaction condition A of embodiment 2, carry out catalyst stability evaluation, the result is as follows image 3 shown. Depend on image 3 It can be seen that the hierarchical porous supported nickel-based catalyst provided by the present application has excellent stability under normal pressure and 800°C reaction conditions, and the conversion rates of carbon dioxide and methane remain basically unchanged within 100 hours of reaction time.

[0068] The transmission electron microscope photos of the catalyst sample CAT-1 before and after the reaction are as follows: Figure 4 shown. Figure 4 (a) is a transmission electron micrograph of the sample CAT-1 before the reaction; Figure 4(b) is a transmission electron micrograph of sample CAT-1 after reacting at 800° C. for 102 hours. It can be seen from the figure tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com