Building material environment-friendly flame-retardant acid-alkaline-treatment-resistant coating

A building material, acid and alkali resistance technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of difficult absorption and poor sound absorption, achieve excellent flame retardant, anti-mildew and antibacterial properties, and improve product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

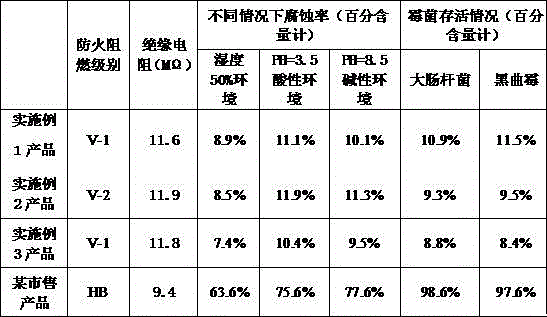

Embodiment 1

[0016] The environmental-friendly, flame-retardant, acid-alkali-resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 20 parts of vermiculite powder, 22 parts of nitroethane, 18 parts of cloves, 16 parts of carnauba wax, bromine 22 parts of benzyl chloride, 18 parts of thifuramide, 16 parts of PVC resin powder, 22 parts of pearl powder, 18 parts of benzoyl peroxide, 16 parts of dioctyl phthalate, 22 parts of triphenyl phosphate, triethylene glycol 18 parts of diisocaprylate, 18 parts of melamine cyanurate, 16 parts of ferrocene, 22 parts of barium stearate, 18 parts of methyltrimethoxysilane, 16 parts of dioctyl sebacate, bisphenol A 22 parts of diglycidyl ether, 18 parts of metallocene polyethylene, 16 parts of glutaric acid, 22 parts of butanetriol, 18 parts of magnesium oxide powder, 16 parts of benzimidazole, 22 parts of allyl sulfide, lauroyl sarcosine 18 parts of sodium bisulfite, 18 parts of sodium b...

Embodiment 2

[0022] The environmental-friendly, flame-retardant, acid- and alkali-resistant treatment coating for building materials in the present embodiment consists of the following components in parts by mass: 22 parts of vermiculite powder, 24 parts of nitroethane, 20 parts of cloves, 18 parts of carnauba wax, bromine 24 parts of benzyl chloride, 20 parts of thifluzamide, 18 parts of PVC resin powder, 24 parts of pearl powder, 20 parts of benzoyl peroxide, 18 parts of dioctyl phthalate, 24 parts of triphenyl phosphate, triethylene glycol 20 parts of diisocaprylate, 20 parts of melamine cyanurate, 18 parts of ferrocene, 24 parts of barium stearate, 20 parts of methyltrimethoxysilane, 18 parts of dioctyl sebacate, bisphenol A 24 parts of diglycidyl ether, 20 parts of metallocene polyethylene, 18 parts of glutaric acid, 24 parts of butanetriol, 20 parts of magnesium oxide powder, 18 parts of benzimidazole, 24 parts of allyl sulfide, lauroyl sarcosine 20 parts of sodium bisulfite, 20 part...

Embodiment 3

[0028]The environmental-friendly, flame-retardant, acid- and alkali-resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 24 parts of vermiculite powder, 26 parts of nitroethane, 22 parts of cloves, 20 parts of carnauba wax, bromine 26 parts of benzyl chloride, 22 parts of thifluzamide, 20 parts of PVC resin powder, 26 parts of pearl powder, 22 parts of benzoyl peroxide, 20 parts of dioctyl phthalate, 26 parts of triphenyl phosphate, triethylene glycol 22 parts of diisocaprylate, 22 parts of melamine cyanurate, 20 parts of ferrocene, 26 parts of barium stearate, 22 parts of methyltrimethoxysilane, 20 parts of dioctyl sebacate, bisphenol A 26 parts of diglycidyl ether, 22 parts of metallocene polyethylene, 20 parts of glutaric acid, 26 parts of butanetriol, 22 parts of magnesium oxide powder, 20 parts of benzimidazole, 26 parts of allyl sulfide, lauroyl sarcosine 22 parts of sodium bisulfite, 22 parts of sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com