Method using microorganism method to convert androstenedione so as to produce testosterone

A technology of codon optimization and hydroxysteroids, which is applied in the fields of genetic engineering and enzyme engineering, can solve the problems of diosgenin consumption, rising saponin price, and low recovery rate, and achieve environmental protection and efficient production of testosterone and raw materials The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

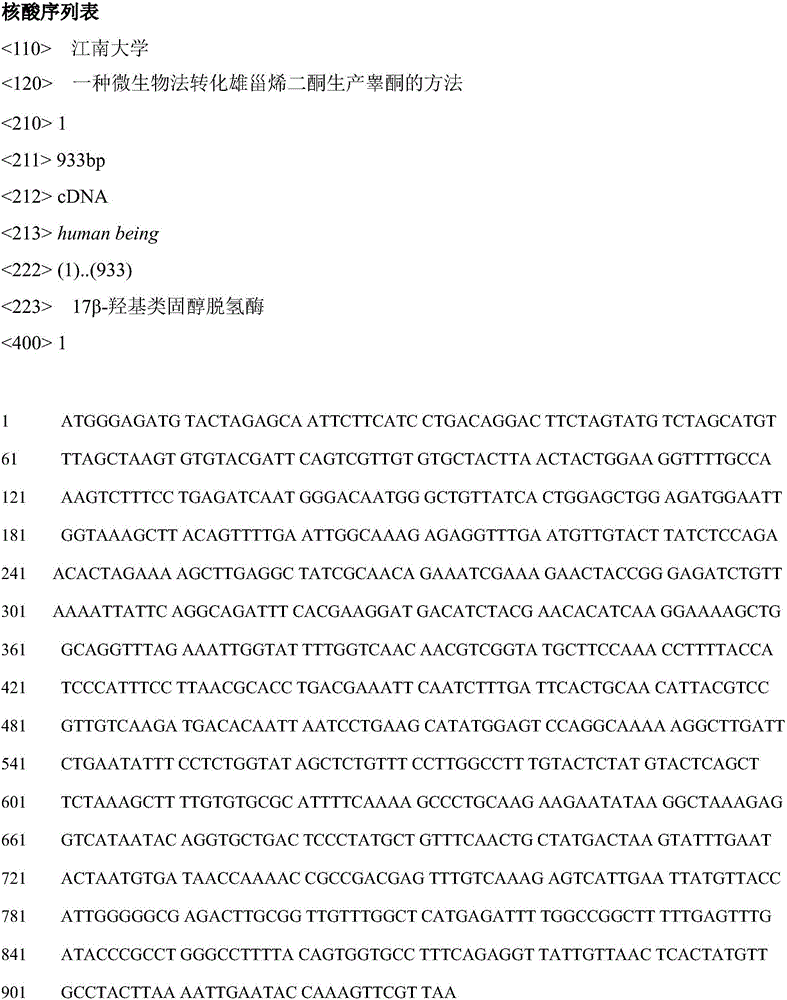

[0033] Embodiment 1: Construction of recombinant Y.lipolytica Polh bacterial strain

[0034] Using the fully synthesized gene in the laboratory as a template, the gene of the enzyme is obtained by means of PCR, and connected to the cloning vector to achieve a large amount of amplification of the gene. A large number of amplified 17β-hsd3 and gdh gene fragments were purified and connected to pINA1292 and pYLSC vectors respectively. After successful verification, the model strain Y. lipolytica Polh was transformed. Positive transformants were screened on the resistance plate, inoculated in shake flasks for fermentation, and the product TS in the fermentation liquid was detected by HPLC. The product TS was detected, indicating that the recombinant strain with the conversion of AD to TS was successfully constructed. The present invention finally obtains the Y. lipolytica Polh strain with high-efficiency conversion of AD to TS.

Embodiment 2

[0035] Embodiment 2: the enzyme activity assay of recombinant bacterial strain

[0036] Enzyme activity determination method: determined by HPLC method. The specific method is as follows: take 50 mL of the bacterial solution cultured for 24 hours, centrifuge at 4°C, 8,000 r / min for 5 minutes to collect the bacterial cells, wash twice with 50 mL of Tris-HCl buffer with pH 7.0, and resuspend in 5 ml of the buffer. Ultrasonic crushing with 40% power in an ice bath, working for 2 seconds and resting for 5 seconds, and working time for 10 minutes. Centrifuge at 10,000r / min for 30min to obtain the supernatant, which contains the target protein. The enzyme activity assay method is as follows: 1 mL of enzyme activity assay system includes 0.5 mM NADPH, 200 μM AD (dissolved in methanol), and then add an appropriate amount of enzyme solution. Definition of enzyme activity unit: at 37°C, the amount of enzyme that converts 1 μmol AD into TS in 1 min is defined as 1 enzyme activity uni...

Embodiment 3

[0037] Example 3: Detection of whole cell transformation performance of recombinant strains

[0038] The strain was inoculated in 100 mL of BMGY medium with 5% inoculum, cultured for 24 h, then inoculated with 5% inoculum in a 5L fermenter containing 2L of BMMY medium, and continuously added methanol for induction for 4 days. The cells were recovered by centrifugation, washed twice, redissolved with a certain amount of 50mM Tris-HCl pH 7.5 buffer, and transformed by adding substrate AD. The solvent was methylated-β-cyclodextrin (1:1 molar ratio), the biomass was 200g / L, and the substrate concentration was 5g / L. After 3 feeding whole cell transformations, 15g / L androstenedione was converted into 14.3g / L testosterone, which is the first time at home and abroad to use androstenedione transformation and production in Pichia pastoris by constructing a NADPH coenzyme cycle regeneration system Testosterone, and ultimately achieve the purpose of increasing the conversion rate and eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com