Preparation method of monodispersed selenium doped nano hydroxyapatite

A nano-hydroxyapatite and selenium doping technology, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of uneven shape and size of nanoparticles, uneven shape and scale of products, and complicated preparation process, etc. problems, to achieve the effect of uniform shape and size, good application prospects, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: In a 40mL polytetrafluoroethylene hydrothermal reaction kettle, dissolve 0.5g of polyethylene glycol 2000 in 7.5mL of 0.25M calcium nitrate aqueous solution, stir for several minutes, then add 16mL of ethanol, 4mL of Oleic acid, 0.45mL of 0.25M sodium selenite aqueous solution and 6.75mL of 0.15M trisodium phosphate solution were stirred evenly at room temperature;

[0021] Step 2: Seal the reaction vessel, react at 120°C for 10 hours, then cool naturally to room temperature, open the reaction vessel, and wash several times with cyclohexane, ethanol and water successively to obtain the final product.

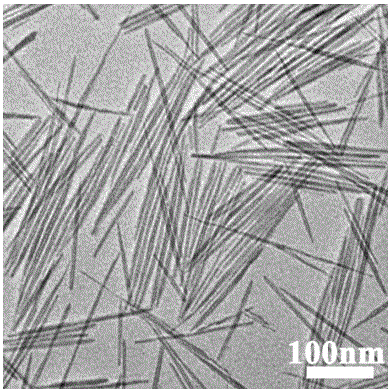

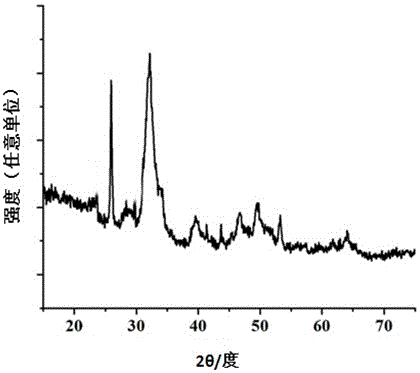

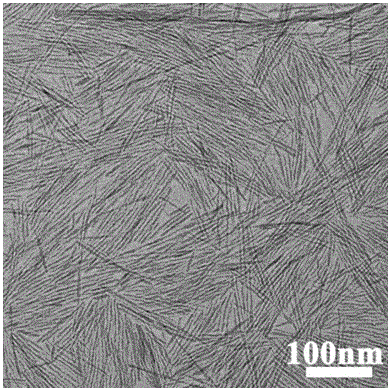

[0022] figure 1 It is a transmission electron microscope image of the selenium-doped hydroxyapatite nanorod, and it can be seen from the figure that the prepared nanoparticle is rod-shaped, with a width of about 9 nm and a length of about 180 nm. figure 2 It is the X-ray diffraction pattern of the nanoparticles, and it can be seen from the figure that the obtain...

Embodiment 2

[0024] Step 1: In a 40mL polytetrafluoroethylene hydrothermal reaction kettle, dissolve 0.5g of polyethylene glycol 1000 in 7.5mL of 0.25M calcium nitrate aqueous solution, stir for several minutes, then add 16mL of ethanol, 4mL of Oleic acid, 0.9mL of 0.25M sodium selenite aqueous solution and 6mL of 0.15M trisodium phosphate solution were stirred evenly at room temperature;

[0025] Step 2: Seal the reaction vessel, react at 90°C for 15 hours, then naturally cool to room temperature, open the reaction vessel, and wash several times with cyclohexane, ethanol and water successively to obtain the final product.

Embodiment 3

[0027] Step 1: In a 40mL polytetrafluoroethylene hydrothermal reaction kettle, dissolve 0.5g of polyethylene glycol 1000 in 7.5mL of 0.25M calcium nitrate aqueous solution, stir for several minutes, then add 16mL of ethanol, 4mL of Oleic acid, 1.35mL of 0.25M sodium selenite aqueous solution and 5.25mL of 0.15M trisodium phosphate solution were stirred evenly at room temperature;

[0028] Step 2: Seal the reactor, react at 150° C. for 5 h, then naturally cool to room temperature, open the reactor, and wash several times with cyclohexane, ethanol and water successively to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com