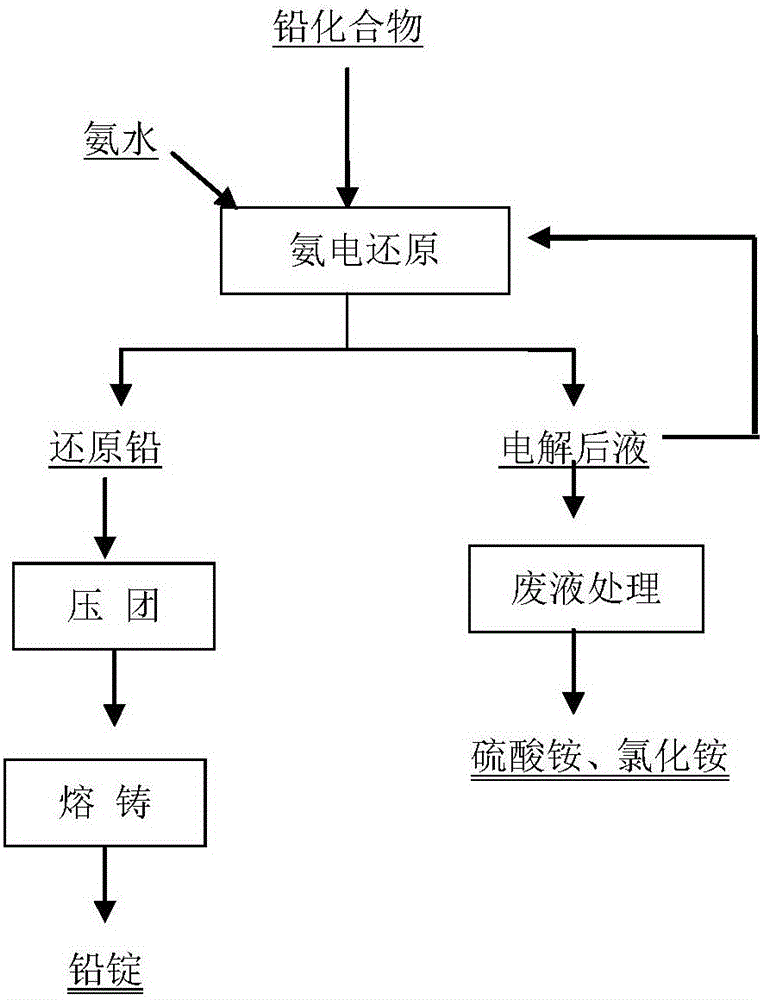

Process for preparing lead by ammonium sulfate through ammonia power reduction

An ammonium sulfate and process technology, which is applied in the field of ammonium sulfate ammonia electroreduction to produce lead, can solve the problems of high energy consumption and environmental pollution of lead smoke and dust, and achieve the effects of low power consumption, low equipment corrosion, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Take 500g of waste lead-acid battery lead paste, containing Pb75.04% (wherein Pb5.2%, PbSO 4 41.06%, PbO 2 44.32%, PbO3.65%);

[0061] (2) get two pieces of titanium nets that are coated with iridium and ruthenium coating as anodes, the width of the anode is 10cm, and the height is 20cm;

[0062] (3) Get a piece of stainless steel as the cathode, the width of the cathode is 10cm, and the height is 20cm;

[0063] (4) Preparation of liquid before electrolysis: prepare 5L of 2mol / L ammonium sulfate solution, add 200ml of ammonia water;

[0064] (5) Reduction: constant voltage mode 2.3v voltage, carry out reduction for 24 hours, use ammonia water to control PH8-9, after reduction is completed, leave the tank;

[0065] (6) The reduced lead weighs 379.8g after compaction, and the result of sampling analysis is Pb98.6%.

[0066] Main technical indicators: initial current 10.5A, peak current 20.5A, reduction power consumption 377.5wh, power consumption per ton of lead ...

Embodiment 2

[0068] (1) Take 500g of waste lead-acid battery lead paste, containing Pb75.04% (wherein Pb5.2%, PbSO 4 41.06%, PbO 2 44.32%, PbO3.65%);

[0069] (2) get two pieces of titanium nets that are coated with iridium and ruthenium coating as anodes, the width of the anode is 10cm, and the height is 20cm;

[0070] (3) Take a piece of lead plate as the cathode, the width of the cathode is 10cm, and the height is 20cm;

[0071] (4) Preparation of liquid before electrolysis: prepare 5L of 2mol / L ammonium sulfate solution, add 200ml of ammonia water;

[0072] (5) Reduction: constant voltage mode 2.5v voltage, carry out reduction for 20 hours, use ammonia water to control PH 8-9, after the reduction is completed, leave the tank;

[0073] (6) The reduced lead weighs 380.1g after compaction, and the result of sampling analysis is Pb98.1%.

[0074] Main technical indicators: initial current 12A, peak current 23A, reduction power consumption 411wh, power consumption per ton of lead 1094k...

Embodiment 3

[0076] (1) make anode with two titanium nets that are coated with iridium ruthenium coating, the anode width is 10cm, and height is 20cm;

[0077] (2) make a cathode with a piece of stainless steel, the width of the cathode is 10cm, and the height is 20cm;

[0078] (3) Feeding intake: lead chloride 1000g, wherein Pb64.3%, Cl 22.4%;

[0079] (4) Electrolyte preparation: take 5L of 2mol / L ammonium sulfate solution, add ammonia water 200ml;

[0080] (5) Reduction: constant voltage mode 2.0v voltage, carry out reduction for 20 hours, use ammonia water to control PH 8-9, after the reduction is completed, leave the tank;

[0081] (6) Reduced lead weighs 656.2g after briquetting, and the result of sampling analysis is Pb98.5%;

[0082] Main technical indicators: initial current 10A, peak current 21.8A, reduction power consumption 336wh, power consumption per ton of lead 523kwh, anode current density 250-545A / m 2 , lead recovery rate 99.8%, ammonia consumption 890ml (containing NH3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com