Ultraviolet imprint lithography fabricating method of micro-hole array cancer cell detecting chip

A detection chip and manufacturing method technology, applied in microstructure technology, microstructure device, microlithography exposure equipment, etc., can solve the problem of low detection accuracy, poor controllability, low efficiency, etc. problem, to achieve the effect of low processing cost, low price and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

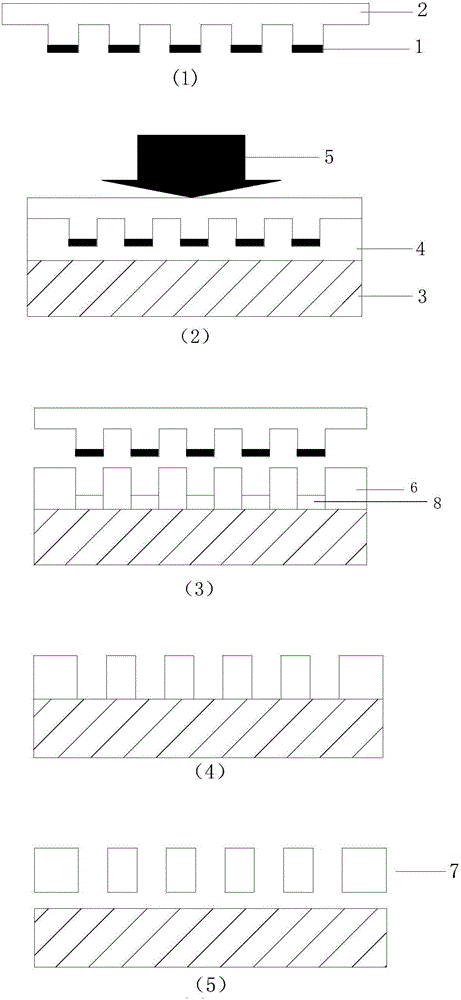

[0028] This embodiment provides a method for making a micro-via array cancer cell detection chip by ultraviolet imprinting. A modified transfer printing uv adhesive material is used as the photosensitive material layer, and the embossing substrate is aluminum foil to make a micro-via array cancer cell detection chip. The specific implementation steps are as follows:

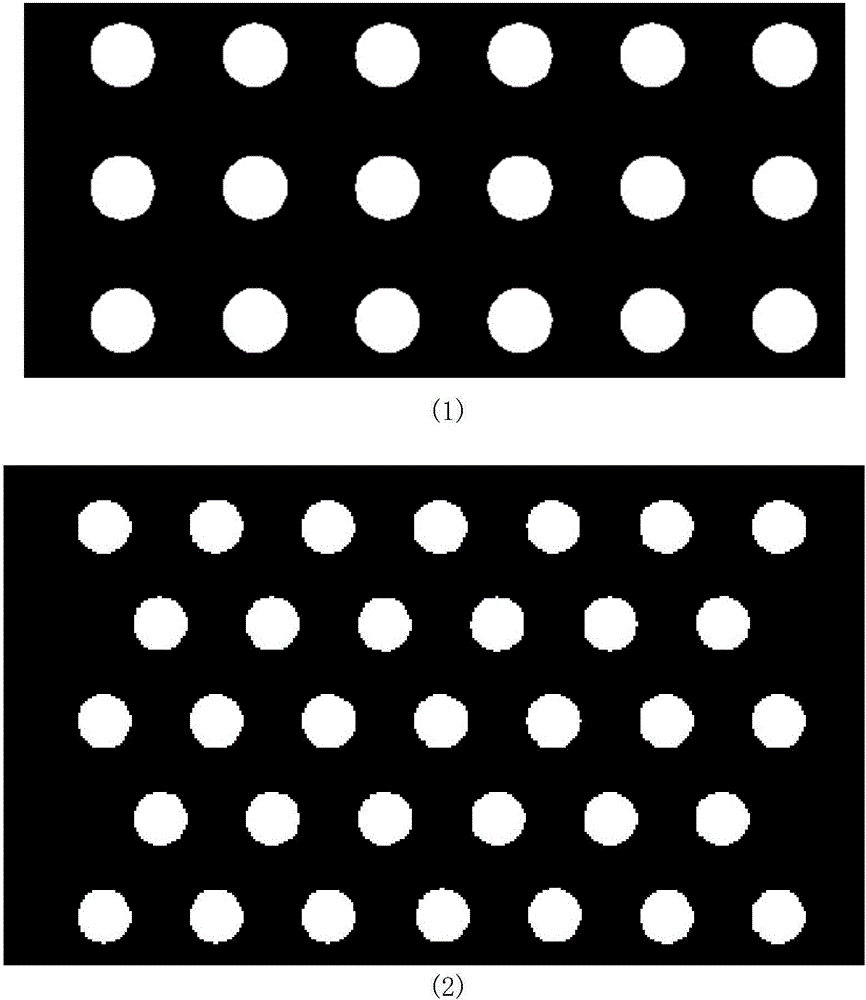

[0029] (1) Fabrication of an imprint stamp, that is, fabrication of a transparent stamp 2 with a metal masking layer 1 . Coat a layer of 2um thick chrome layer on the quartz substrate with a magnetron sputtering coating machine, and then coat az1500 photoresist on the surface of the chrome layer with a thickness of 2um, pre-bake at 100°C for 10min on a hot plate, and then expose to 365nm ultraviolet light Under the machine, use a mask plate with a cylinder diameter of 6um, a square arrangement, and a column-to-space ratio of 1:20, using a contact exposure method with an exposure dose of 100mJ / cm 2 , developing f...

Embodiment 2

[0035] This embodiment provides a UV imprinting method for manufacturing a micro-via array cancer cell detection chip. The modified transfer printing uv adhesive material is used as the photosensitive material layer, and the embossing substrate is copper foil to make a micro-via array cancer cell detection chip. , the specific implementation steps are as follows:

[0036] (1) The production of imprint stamps, that is, the production of transparent stamps with metal masking layers. Use a vacuum evaporation coating machine to coat a layer of 500nm thick chromium layer on the pmma substrate treated with a release agent, and then coat SU8 photoresist on the surface of the chromium layer with a thickness of 10um, pre-bake on a hot plate at 95°C for 10min, and then Under a 365nm ultraviolet exposure machine, using a mask plate with a diameter of 15um circular holes, a hexagonal arrangement, and a hole-to-space ratio of 1:10, the contact exposure method is adopted, and the exposure d...

Embodiment 3

[0042] This embodiment provides a UV imprinting manufacturing method of micro-via array cancer cell detection chip, using modified transfer printing uv glue material as the photosensitive material layer, and the imprinting substrate is made of water-soluble uv glue material to make micro-via array cancer The specific implementation steps of the cell detection chip are as follows:

[0043] (1) The production of imprint stamps, that is, the production of transparent stamps with metal masking layers. A 100nm thick chromium layer is plated on the fluorinated resin material substrate using an electron beam evaporation coating machine, and then coated with SU8 photoresist on the surface of the chromium layer, the thickness of the glue is 20um, pre-baked at 95°C on a hot plate for 10min, and then heated at 365nm Under the ultraviolet exposure machine, using a mask plate with a diameter of 50um circular holes, a quadrilateral arrangement, and a hole-to-space ratio of 1:1, the contact ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com