A kind of flexible carbon film and preparation method thereof

A carbon film and flexible technology, which is applied in the field of preparing high-performance flexible carbon film, can solve the problems of small average grain size, few defects, and poor flexibility, and achieve the effects of less defects, improved brittleness, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

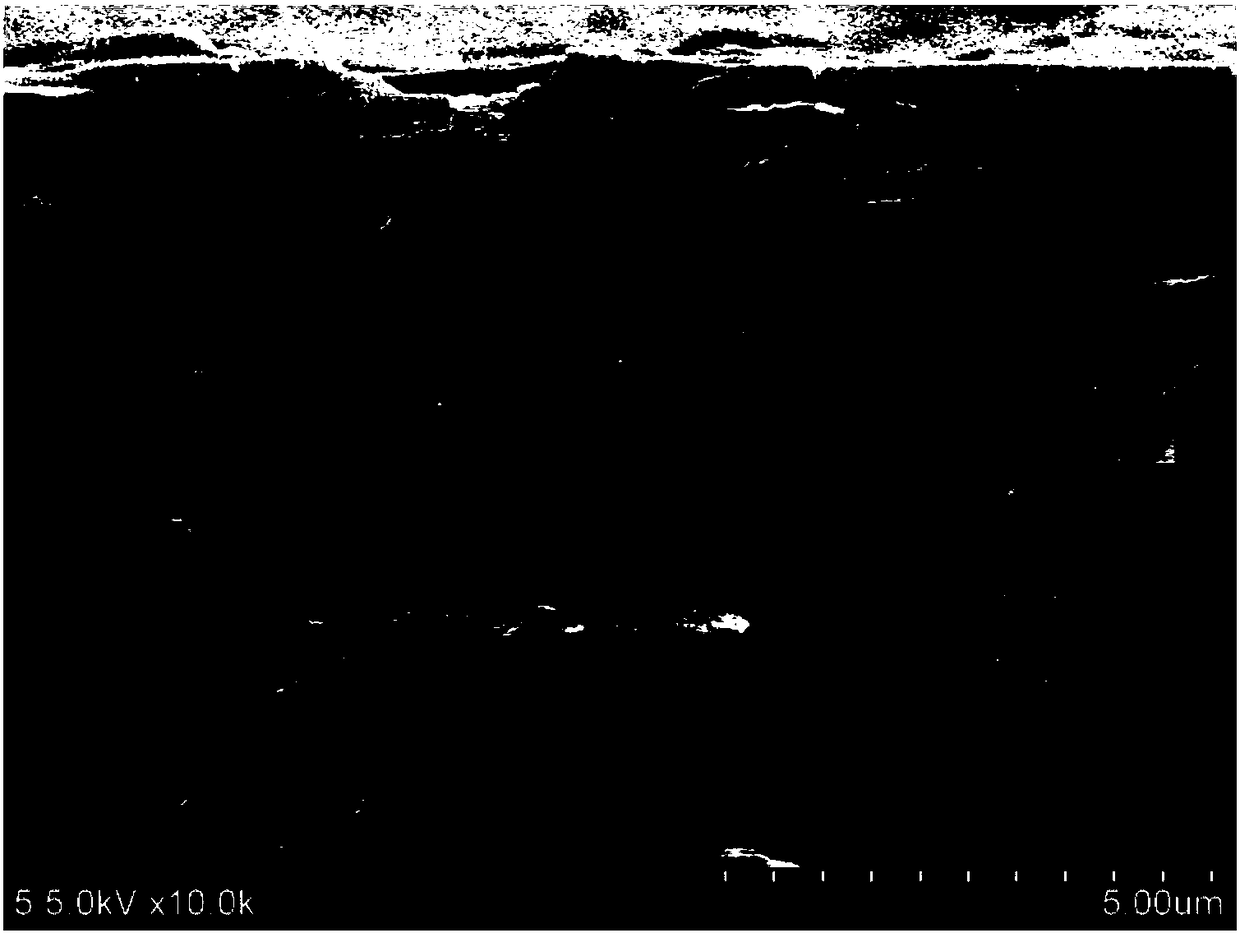

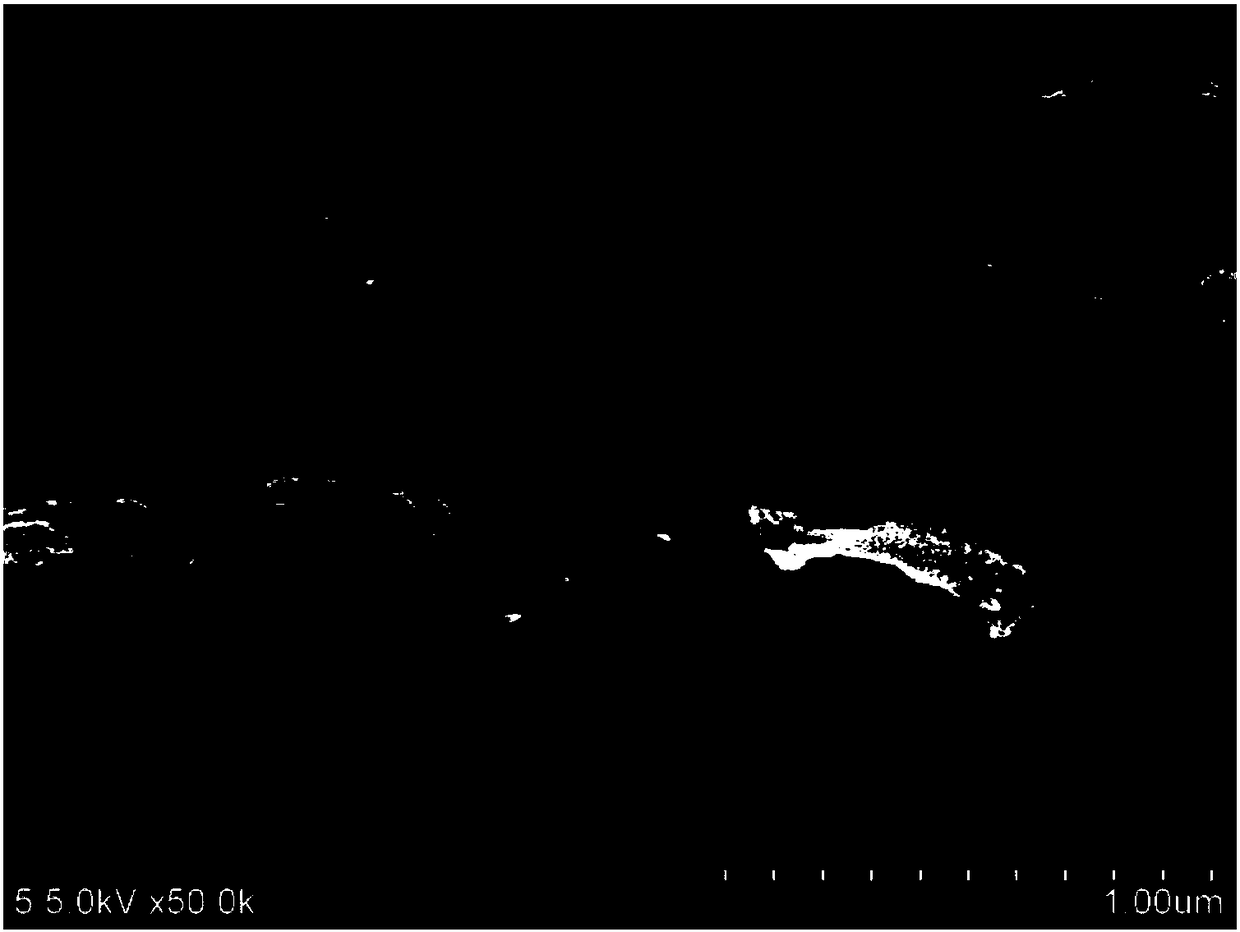

Image

Examples

Embodiment 1

[0055] A kind of preparation method of flexible carbon membrane, by blending method, the graphene oxide dispersion liquid that concentration is 0.5wt% and the polyacrylonitrile (polyacrylonitrile that comprises the first monomer acrylonitrile) solution that concentration is 9wt% pass through Mechanical stirring and mixing; the graphene oxide dispersion needs to be ultrasonically dispersed before use. The treatment time is 0.5 hours and the temperature is 10°C. The graphene oxide dispersion contains the same solvent as the polyacrylonitrile solution, and the solvent is dimethylformamide. The time of mechanical stirring and mixing is 1h, the rotating speed is 50 rpm, and the temperature is 10°C; then the solution is subjected to vacuum defoaming treatment for 0.5h to obtain a graphene oxide / polyacrylonitrile composite solution; the prepared graphene oxide / polyacrylonitrile The concentration of polyacrylonitrile in the polyacrylonitrile composite solution is 20wt%, and the mass fr...

Embodiment 2

[0058] A kind of preparation method of flexible carbon membrane, by in-situ polymerization method, the concentration is the monomer (the monomer comprises the first monomer acrylonitrile) solution of 10wt%, the initiator azobisisobutyronitrile and the concentration of 0.5wt% The graphene dispersion liquid is mixed evenly to make a polymerization solution; the graphene dispersion liquid needs to be dispersed by magnetic stirring before use, the processing time is 12 hours, the temperature is 40 ° C, the graphene dispersion liquid and the polyacrylonitrile solution contain the same solvent, The solvent is dimethyl sulfoxide; the mass fraction of the initiator relative to the monomer is 0.3%; the mass fraction of the graphene relative to the monomer is 0.1%; then polymerize at normal pressure for 1h at 50°C, and then vacuum defoam the solution Treat for 12h to obtain the graphene / polyacrylonitrile composite solution; the conversion rate of the monomer in the prepared graphene / poly...

Embodiment 3

[0061] A kind of preparation method of flexible carbon film, by blending method, concentration is the graphene dispersion liquid of 5wt% and the polyacrylonitrile (comprising the polyacrylonitrile of the first monomer and the polyacrylamide of the second monomer acrylamide) that the concentration is 39wt% Acrylonitrile, wherein the mass fraction of acrylonitrile relative to the total monomer is 80%, and the mass fraction of acrylamide relative to the total monomer is 20%) solution is mixed by mechanical stirring; the graphene dispersion needs to be dispersed through mechanical stirring before use. The time is 10 hours, the temperature is 35 °C, the graphene dispersion and the polyacrylonitrile solution contain the same solvent, and the solvent is dimethylacetamide; the mechanical stirring and mixing time of the graphene dispersion and the polyacrylonitrile solution is 24 hours, and the rotation speed The temperature is 1500 rpm, and the temperature is 50°C; then the solution is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com