Nickel selenide/hollow carbon-fibre composite and preparation method thereof

A composite material, carbon fiber technology, applied in chemical instruments and methods, chemical/physical processes, nanotechnology for materials and surface science, etc. The effect of ingenious experimental design, effective and quick preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

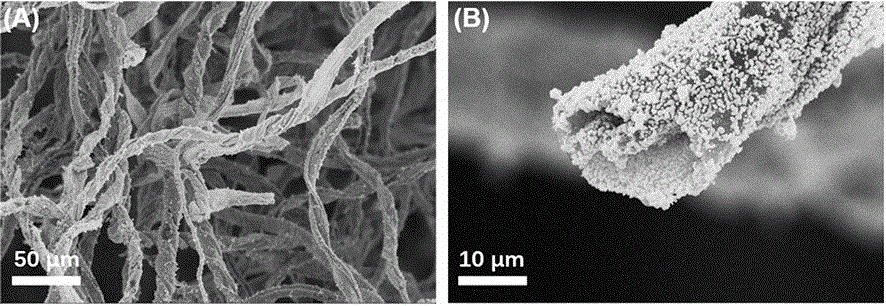

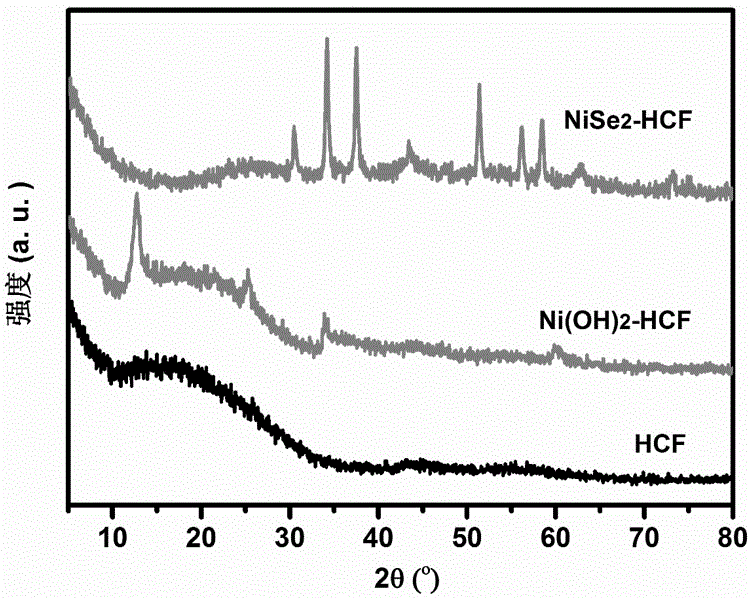

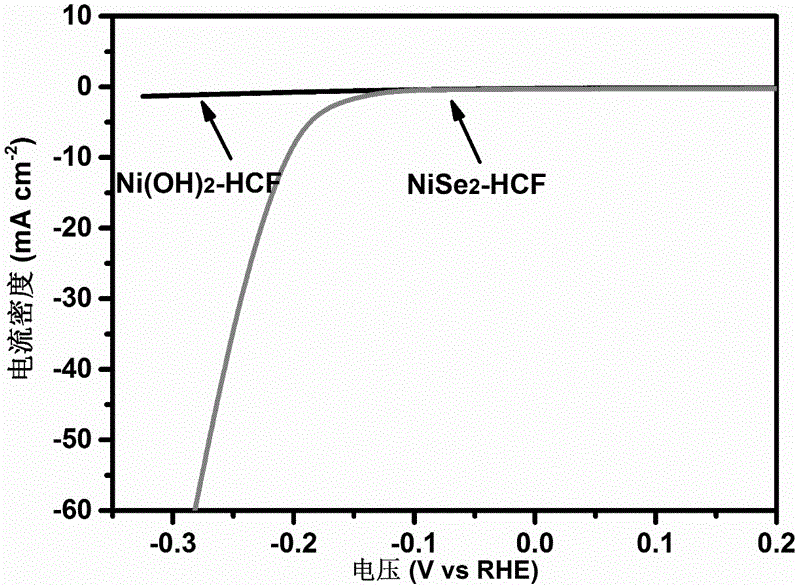

[0029] Embodiment 1, the present embodiment comprises the following steps:

[0030] (1) Place the cotton in high-purity nitrogen gas for high-temperature carbonization. The high-temperature carbonization temperature is 900°C, and the high-temperature carbonization time is 2 hours to prepare hollow carbon fibers;

[0031] (2) Dissolve 1 mmol of nickel nitrate hexahydrate and 3 mmol of urea in a mixture of 30 mL of ethanol and water (volume ratio 2:1), and stir for a period of time to disperse them evenly;

[0032] (3) After immersing 5 mg of hollow carbon fibers into the mixture prepared in (4), heat them in a water bath to 80 °C and react for 7 h. After cooling down naturally, take out the carbon fibers and wash them repeatedly with deionized water and ethanol and dry them to obtain Nickel hydroxide / hollow carbon fiber composite material, denoted as Ni(OH) 2 -HCF;

[0033] (4) Place the prepared nickel hydroxide / hollow carbon fiber composite material in the lower tuyere of t...

Embodiment 2

[0034] Example 2, change the selenization temperature in Example 1 to 400°C, the rest are the same as in Example 1, and the finally obtained composite material is denoted as NiSe 2 -HCF-2.

Embodiment 3

[0035] Example 3, change the selenization temperature in Example 1 to 450°C, the rest are the same as in Example 1, and the finally obtained composite material is denoted as NiSe 2 -HCF-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com