Graphite-C3N4-doped TiO2-loaded expanded perlite floating type environment restoration material capable of removing organic pollutants and preparation method of environment restoration material

A technology of organic pollutants and expanded perlite, which is applied in the field of environmental restoration, can solve the problems of easy aggregation and sedimentation of TiO2, low photocatalytic efficiency, and difficult filtration and separation, etc., to achieve improved visible light adsorption, simple synthesis process, and controllable hydrolysis degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

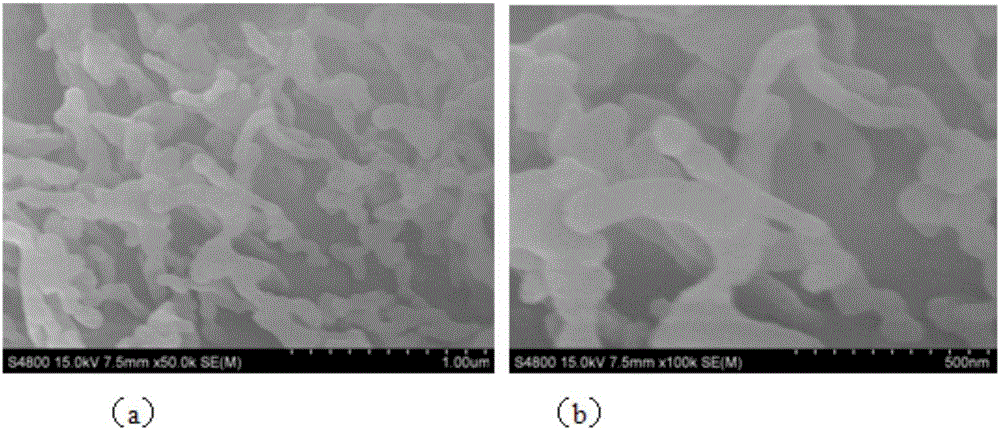

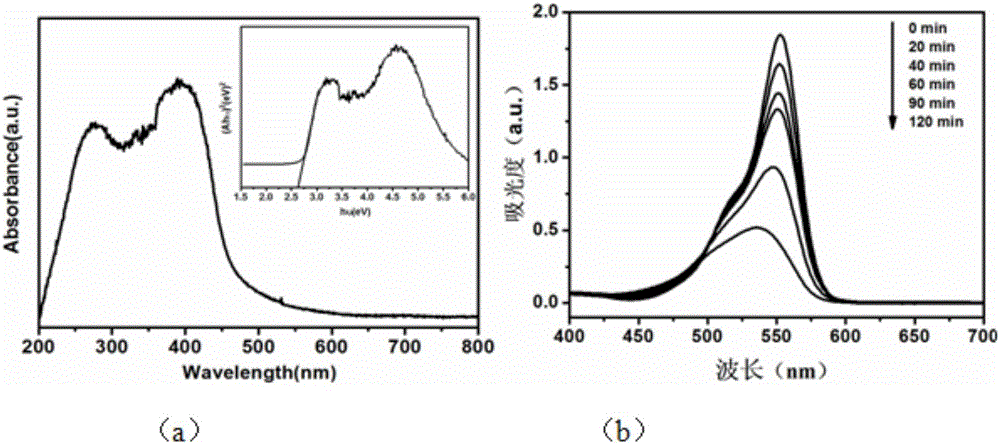

[0030] Take a certain amount of melamine, put a certain quality of melamine into an alumina crucible, and calcinate at 500°C for 2 hours in a nitrogen atmosphere, and then at 520°C for 2 hours. The obtained solid sample is ground to obtain g-C 3 N 4 . Its scanning electron microscope picture is as figure 1 As shown, the calcined melamine has a rod-like structure, and the diameter of the material is about 50nm.

[0031] Take 0.1g of g-C 3 N 4 Add 50mL rhodamine B solution to a 50mL quartz tube, absorb in dark for 1.5 h, and illuminate with 500w xenon lamp for 2h. Rhodamine B solution concentration: 10mg / L. And the UV bandgap width of the material is measured to be about 2.7eV, such as image 3 (a), consistent with the literature, has good absorption in the visible region. Such as image 3 (b), the degradation rate of rhodamine B was measured to be 80%.

example 2

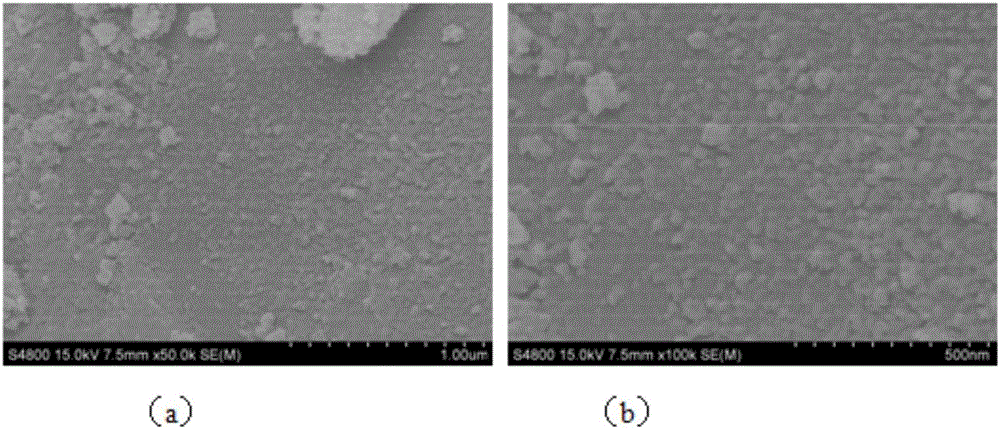

[0033] Take 10ml of absolute ethanol and 5~7ml of titanium isopropoxide into a beaker and stir to obtain solution A. Add a certain amount of water to 0.5g of melamine and add 5~7ml of acetic acid to obtain solution B. Stir with a magnetic stirrer at room temperature. Put the 10-20 mesh expanded perlite particles obtained after washing, air-drying and sieving into solution A, and add solution B dropwise to the mixture of solution A and expanded perlite to obtain a stable and uniform transparent sol. Aging at room temperature for 24 hours; drying the perlite in a tube furnace under a nitrogen atmosphere (300-400ml / min) at 420°C for 1 hour to obtain C 3 N 4 -TiO 2 Loaded environmental remediation materials.

[0034] Take 0.1g of C 3 N 4 -TiO 2 Add @EP and 50mL rhodamine B solution into a 50mL quartz tube, absorb in dark for 1.5 h, and illuminate with 500w xenon lamp for 4h. Rhodamine B solution concentration: 10mg / L. Such as Figure 4 (a), the measured solid UV band gap i...

example 3

[0036] Take 10ml of absolute ethanol and 5~7ml of titanium isopropoxide into a beaker and stir to obtain solution A. Add a certain amount of water to 0.5g of melamine and add 5~7ml of acetic acid to obtain solution B. Stir with a magnetic stirrer at room temperature. Put the 10-20 mesh expanded perlite particles obtained after washing, air-drying and sieving into solution A, and add solution B dropwise to the mixture of solution A and expanded perlite to obtain a stable and uniform transparent sol. Aging at room temperature for 24 hours; drying the perlite in a tube furnace under an ammonia atmosphere (300-400ml / min) at 420°C for 1 hour to obtain C 3 N 4 -N-TiO 2 Loaded environmental remediation materials.

[0037] Take 0.1g of C 3 N 4 -N-TiO 2 Add @EP and 50mL rhodamine B solution into a 50mL quartz tube, absorb in dark for 1.5h, and illuminate with 500w xenon light for 4h. Rhodamine B solution concentration: 10mg / L. Such as Figure 5 (a), its measured solid UV band g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com