Composite zeolite membrane, and preparation method and application thereof

A technology of molecular sieve membranes and molecular sieves, which is applied in applications, other household appliances, chemical instruments and methods, etc., can solve the problems of discontinuous molecular sieve layer shedding, low porosity molecular sieve membranes, and difficulty in seed crystal coating, etc. Controlling, small channel tortuosity, smooth and continuous surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

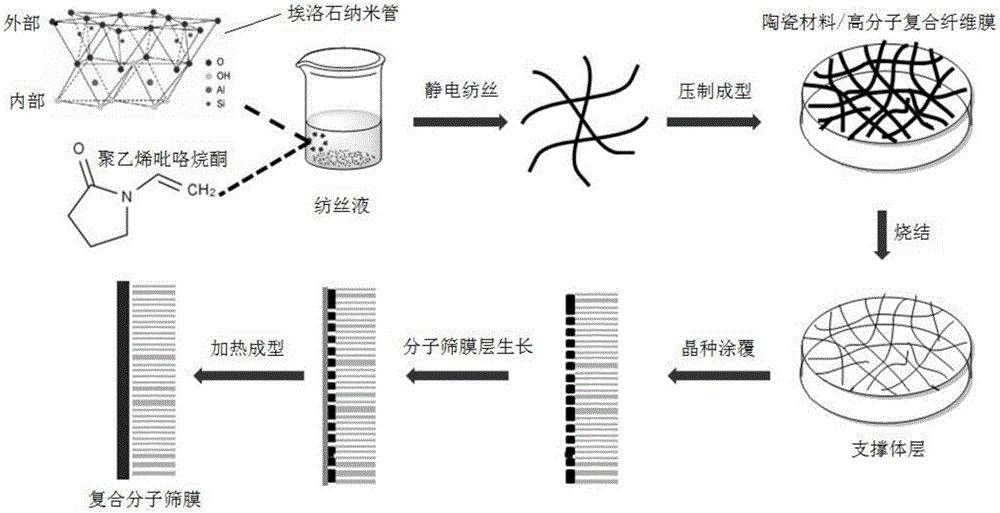

[0067] Taking the preparation of the molecular sieve membrane layer by the secondary growth method as an example, the preparation method of the composite molecular sieve membrane of the present application is illustrated, such as figure 1 shown, including the following steps,

[0068] (1) Disperse nanoscale or submicron ceramic powder materials or ceramic material precursors in a solvent, add a high molecular polymer, stir evenly, and make a spinning solution for electrospinning;

[0069] (2) Utilize the electrospinning method to make the spinning solution into a ceramic material / polymer composite fiber membrane;

[0070] (3) Carry out pretreatment to ceramic material / polymer composite fiber membrane, carry out compression molding after pretreatment;

[0071] (4) Sintering the compressed composite fiber membrane, removing the high molecular polymer, and obtaining a support layer;

[0072] (5) Adopt secondary growth method to form continuously distributed molecular sieve film...

Embodiment 1

[0075] This example provides a method for preparing a high-porosity porous ceramic support layer, specifically as follows.

[0076] N, N-dimethylformamide (abbreviated as DMF) and ethanol (abbreviated as EtOH) were weighed to prepare a mixed solution at a mass ratio of 1:2.

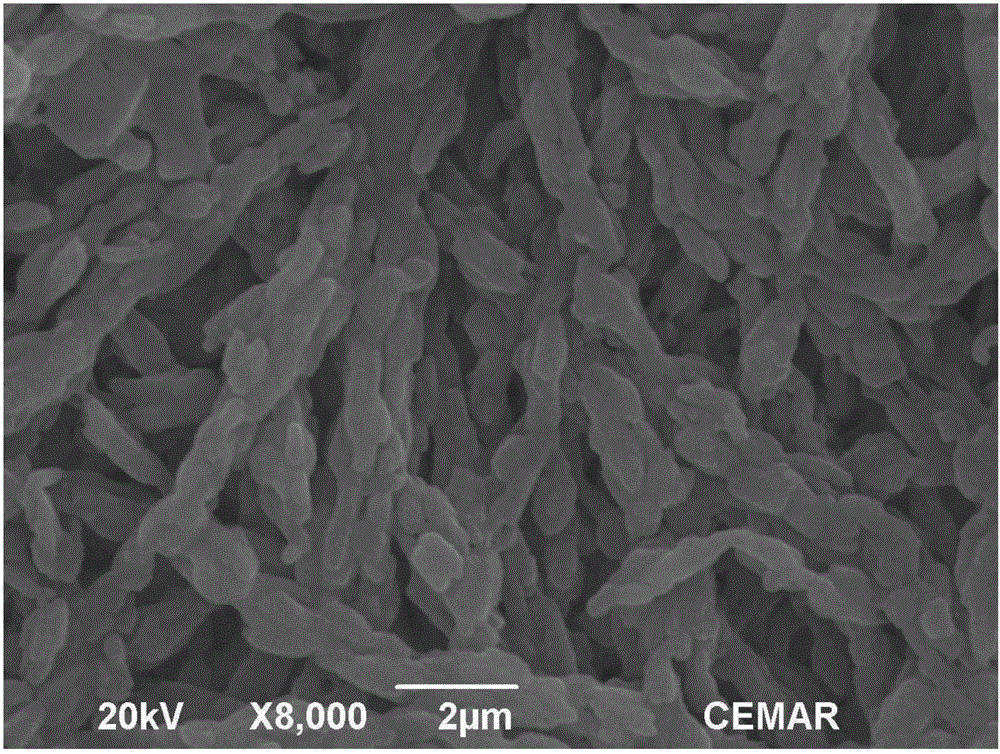

[0077] Halloysite nanotubes (abbreviated as HNTs) were weighed and added to the above mixed solvent, and ultrasonically dispersed until no agglomeration state. Add polyvinylpyrrolidone (PVP for short), and make the mass ratio of PVP to the mixed solution 3:22, and the mass ratio of HNTs to PVP 2:3; mix thoroughly to obtain a uniform spinning solution.

[0078] The electrospinning process with a needle was adopted, and the prepared spinning solution was placed in a disposable syringe with a needle inner diameter of 0.4 mm for electrospinning. The electrospinning voltage was set at 5KV, the solution pumping speed was 30 μL / min, the distance from the needle to the collection drum was 10 cm, and the rotation...

Embodiment 2

[0085] This example provides another method for preparing a high-porosity porous ceramic support layer, as follows.

[0086] Weigh water and ethanol to prepare a mixed solution with a mass ratio of 1:8.

[0087] The halloysite nanotubes (HNTs) were added to the above mixed solvent, and ultrasonically dispersed to a non-agglomerated state. Add polyvinylpyrrolidone (PVP), and make the mass ratio of PVP to the mixed solution 3:22, and the mass ratio of HNTs to PVP 2:3; mix thoroughly to obtain a uniform spinning solution.

[0088] The needle-free electrospinning technology is adopted, and the prepared spinning solution is placed in a liquid carrier device for electrospinning. The electrospinning voltage is set to 60KV, the distance between the receiving electrode and the spinning electrode is 240mm, the moving speed of the liquid carrier device is 300mm / s, and the moving speed of the collecting substrate is 10mm / min, and the ceramic material / polymer composite fiber membrane can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com