A high-efficiency degreaser for oilfield polymer flooding produced water

A degreaser and polymer technology, applied in the direction of grease/oily substance/suspton removal device, flocculation/sedimentation water/sewage treatment, separation method, etc., can solve complex and changeable operation methods, poor demulsification effect, no Applicable to the oil removal treatment of polymer-containing sewage, etc., to achieve the effects of strong neutralization ability, improved oil removal efficiency, and high oil removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Degreaser A 1 And its preparation method

[0025] (1) Degreaser A 1 The composition and components are as follows:

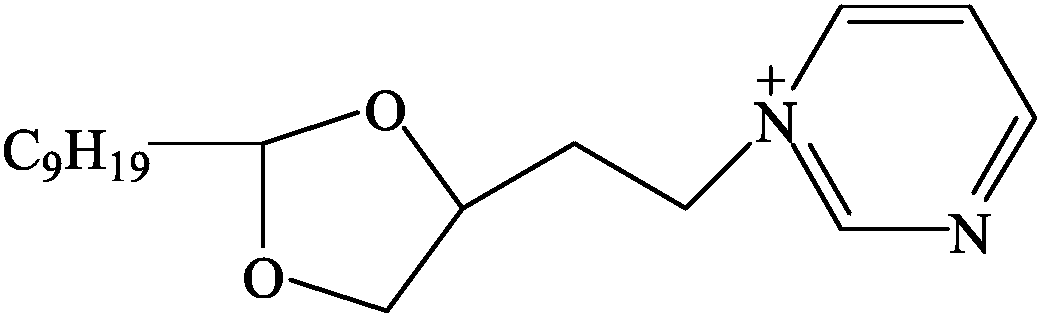

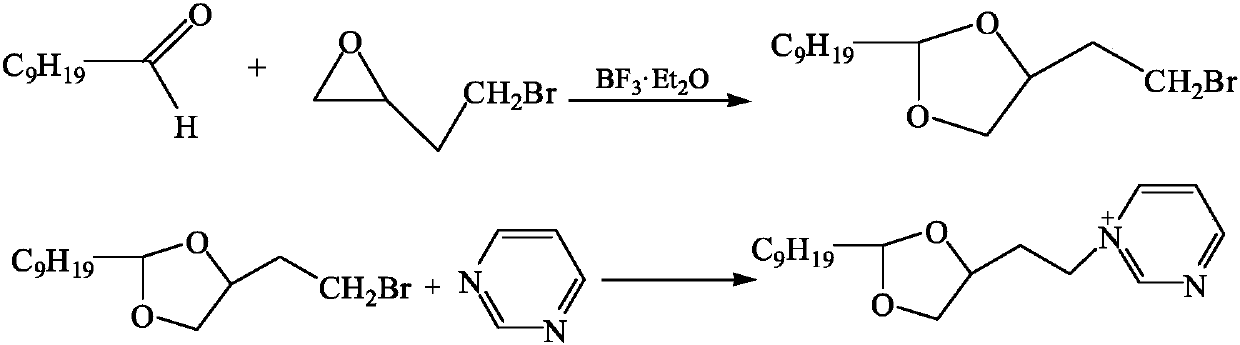

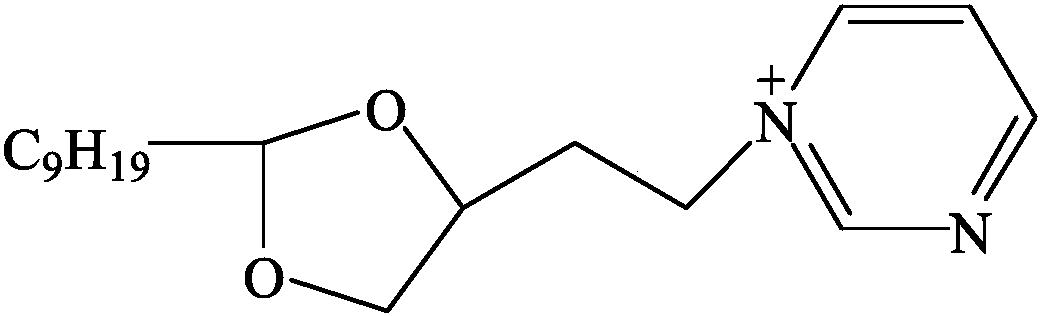

[0026] Degreaser A 1 It is produced by reacting n-decanal with epibromobutane under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacting with pyrimidine to form a cationic degreasing agent. Its molecular formula is as follows:

[0027]

[0028] Among them, the molar ratio of n-decanal, epibromobutane and pyrimidine is 1:1.2:0.9.

[0029] (2) Degreaser A 1 The preparation method is as follows:

[0030] ①In a three-necked flask equipped with an electric stirrer, reflux condenser and thermometer, add 1 mol of n-decanal, then add 1872g of carbon tetrachloride, heat to 30℃, stir at 300rpm for 10min, then add 0.078g A 30% mass concentration of boron trifluoride ether solution, 1.2 mol of epibromobutane is placed in a constant pressure dropping funnel, the dropping rate is controlled to 2 drops / min, the temperature is ra...

Embodiment 2

[0033] Example 2: Degreaser A 2 And its preparation method

[0034] (1) Degreaser A 2 The composition and components are as follows:

[0035] Degreaser A 2 It is produced by reacting n-decanal with epibromobutane under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacting with pyrimidine to form a cationic degreasing agent. Its molecular formula is as follows:

[0036]

[0037] Among them, the molar ratio of n-decanal, epibromobutane and pyrimidine is 1:0.75:0.5.

[0038] (2) Degreaser A 2 The preparation method is as follows:

[0039] ①In a three-necked flask equipped with an electric stirrer, reflux condenser and thermometer, add 1 mol of n-decanal, then add 1560 g of acetonitrile, heat to 32°C, stir at 350 rpm for 25 min, and then add 0.10 g of mass concentration to 30% boron trifluoride ether solution, put 0.75mol of epibromobutane into the constant pressure dropping funnel, control the dropping rate to 3 drops / min, heat up to 50℃, stir at 400...

Embodiment 3

[0042] Example 3: Degreaser A 3 And its preparation method

[0043] (1) Degreaser A 3 The composition and components are as follows:

[0044] Degreaser A 3 It is produced by reacting n-decanal with epibromobutane under the catalysis of boron trifluoride ether solution to form an intermediate, and then reacting with pyrimidine to form a cationic degreasing agent. Its molecular formula is as follows:

[0045]

[0046] Wherein, the molar ratio of n-decanal, epibromobutane and pyrimidine is 1:1.5:2.

[0047] (2) Degreaser A 3 The preparation method is as follows:

[0048] ①In a three-necked flask equipped with an electric stirrer, reflux condenser and thermometer, add 1 mol of n-decanal, then add 2340g of carbon tetrachloride, heat to 35°C, stir at 400rpm for 30min, then add 0.156g A 30% mass concentration of boron trifluoride diethyl ether solution, 1.5 mol of epibromobutane is placed in a constant pressure dropping funnel, the dropping rate is controlled to 4 drops / min, the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com