Method for producing isopentane product

A production method, the technology of isopentane, which is applied in the direction of adsorption purification/separation, organic chemistry, etc., can solve the problems such as no high-purity isopentane products, and achieve improved cycle adsorption capacity, high selectivity, and increased desorption push force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

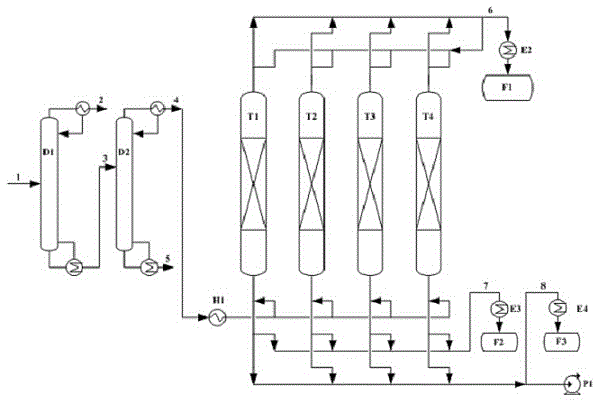

[0034] Using light naphtha as raw material and SAPO-17 aluminum phosphate molecular sieve as adsorbent, the composition of light naphtha is shown in Table 1, and the distillation-adsorption coupling process flow is as follows figure 1 shown.

[0035] Compound name Content (wt. %) Isobutane 0.71 n-butane 3.12 Isopentane 38.36 n-pentane 11.42 2,2-Dimethylbutane 0.19 2,3-Dimethylbutane 5.91 2-Methylpentane 24.81 3-Methylpentane 11.45 n-Hexane 2.08 Methylcyclopentane 1.33 benzene 0.62

[0036] The four-tower (T1, T2, T3, T4) pressure swing adsorption cycle process and time distribution are shown in Table 2. The time of a pressure swing adsorption cycle is 20 minutes, of which adsorption is 5 minutes, average pressure drop is 2.5 minutes, reverse discharge is 2.5 minutes, Desorb for 5 minutes, equalize pressure for 2.5 minutes, and pressurize for 2.5 minutes.

[0037] Table 2 Process and time allocat...

Embodiment 2

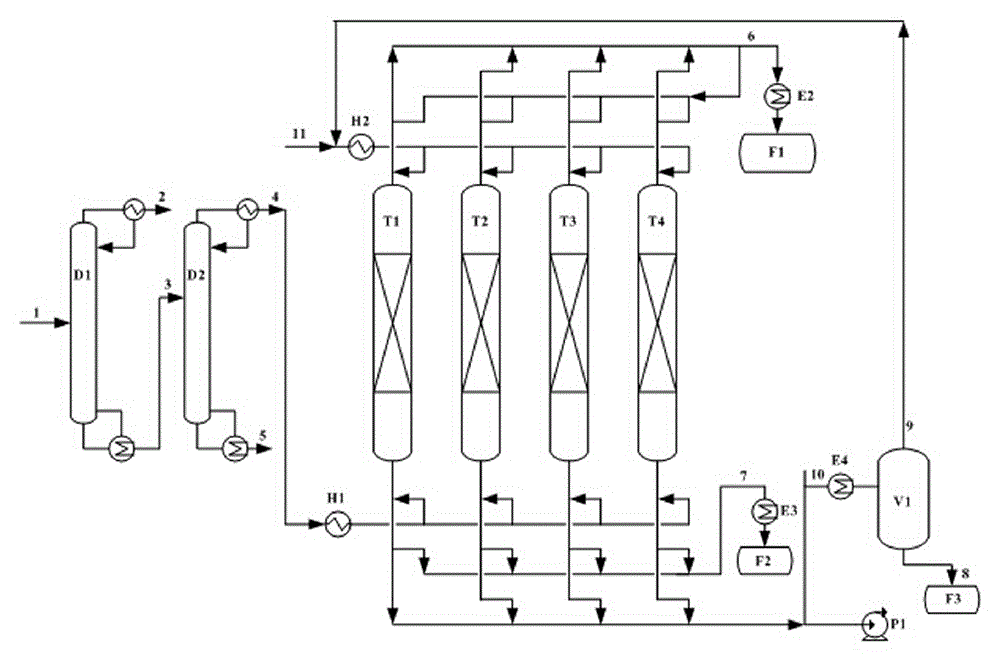

[0042] Such as figure 2 shown. The pressure swing adsorption process, specific operation process and steps are the same as in Example 1. The difference is that the adsorption temperature is 60° C., the adsorption pressure is 0.1 MPa, and the desorption adopts vacuuming while using N 2 Purging, the desorption pressure is 0.05MPa, the desorbed N2 and the desorbed oil mixture 10 are condensed into the gas-liquid separation tank V1 through the desorption oil heat exchanger E4, and the n-pentane (desorbed Oil 8) then enters the desorption oil storage tank F3; the cycle N separated from the gas-liquid separation tank V1 2 9 and Fresh N 2 11 was used again for purge desorption. The content of the obtained isopentane product was 99.4wt%.

Embodiment 3

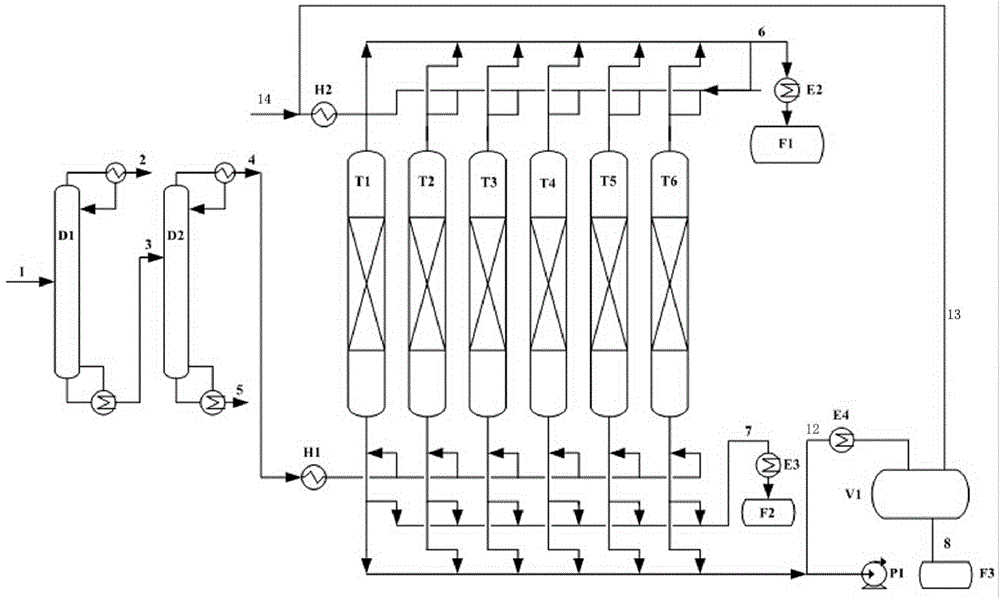

[0044] Using oilfield light hydrocarbons as raw materials and mordenite as adsorbent, the composition of oilfield light hydrocarbons is shown in Table 3, and the schematic diagram of the coupling process of rectification and six-column adsorption is shown in image 3 shown.

[0045] Compound name Content (wt. %) Isobutane 1.33 n-butane 24.37 Isopentane 38.53 2-Methyl-1-butene 0.27 n-pentane 26.61 2-Methyl-2-butene 0.05 2,2-Dimethylbutane 2.34 Cyclopentane 5.58 2-Methylpentane 0.92

[0046] The pressure swing adsorption and time distribution of the six towers (T1, T2, T3, T4, T5, T6) are shown in Table 4. During the adsorption cycle, there are always two adsorption towers simultaneously adsorbing and desorbing, and one pressure swing adsorption cycle is 24 minutes, including adsorption for 6 minutes, average pressure drop for 1.5 minutes, reverse discharge for 1.5 minutes, desorption for 5 minutes, average pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com