Degradable medical Zn-Li-Fe ternary alloy material, preparation and application

A ternary alloy and alloy material technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of process duplication, slow corrosion rate, increased alloy cost, etc., achieves simple alloy preparation process, improved strength and plasticity, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

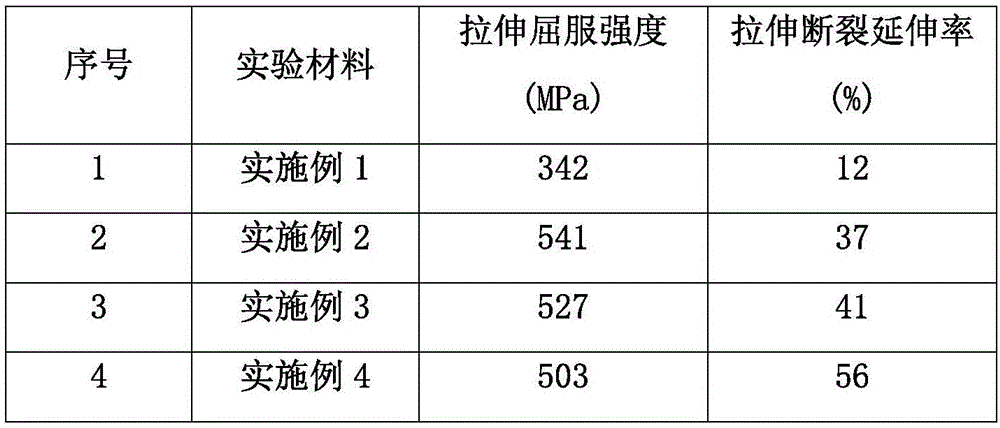

Examples

Embodiment 1

[0035] This embodiment relates to a degradable medical Zn-Li-Fe alloy material, which includes the following alloy components in weight percentage: Zn: 99.5%, Li: 0.4%, Fe: 0.1%.

[0036] The preparation steps of the alloy material are as follows:

[0037] S1. Weigh each raw material according to the above alloy ratio;

[0038]S2. Put pure zinc (purity ≥ 99.995%) into a crucible with a coating on the inner wall, raise the temperature to 420°C until the pure zinc is completely melted, add pure iron wire when the zinc melt is heated to 600°C, and wait for the pure iron wire to pass through After the corrosion and diffusion reaction with the zinc melt is completely melted, add LiCl and LiF mixed flux (mass ratio: 1:3) at 600°C, and after the above mixed solvent completely covers the surface of the melt, then lower the temperature of the melt to To 550°C, at this time, add pure lithium (purity ≥ 99.999%) under the protection of Ar gas, and after the pure lithium is melted, stir e...

Embodiment 2

[0042] This embodiment relates to a degradable medical Zn-Li-Fe alloy material, which includes the following alloy components in weight percentage: Zn: 95.2%, Li: 4.0%, Fe: 0.8%.

[0043] The preparation steps of the alloy material are as follows:

[0044] S1. Weigh each raw material according to the above alloy ratio;

[0045] S2. Put pure zinc (purity ≥ 99.995%) into an iron crucible with a protective coating on the inner wall, heat up to 420°C and wait for the pure zinc to completely melt, add pure iron wire when the zinc melt is heated up to 610°C, and wait for the pure After the iron wire is completely melted through the corrosion diffusion reaction with the zinc melt, then add LiCl and LiF mixed flux (mass ratio is 1:3) at 610 ° C, and after the above mixed solvent completely covers the surface of the zinc melt, then add the zinc The temperature of the melt drops to 540°C. At this time, pure lithium (purity ≥ 99.999%) is added under the protection of Ar gas, and after t...

Embodiment 3

[0049] This embodiment relates to a degradable medical Zn-Li-Fe alloy material, which includes the following alloy components in weight percentage: Zn: 97.7%, Li: 2.0%, Fe: 0.5%.

[0050] The preparation method of this alloy material is the same as embodiment 1, and difference is:

[0051] S2. Add pure zinc and heat up to 420°C. After the pure zinc is completely melted, add pure iron powder when the melt temperature rises to 580°C. After it is completely melted, add LiCl and LiF at the same temperature (580°C). Mixing flux (mass ratio is 1:3), after the above-mentioned mixed solvent completely covers the surface of the zinc melt, then lower the temperature of the zinc melt to 540°C, at this time, add pure lithium under the protection of Ar gas;

[0052] S3. The refining temperature is 530±10°C, and the amount of hexachloroethane is 0.2% of the total weight of the alloy melt; after refining, stand still at 530±10°C for 30 minutes;

[0053] S4. The homogenization treatment temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com