Drilling fluid additive composition suitable for coal-bed gas wells and its application, water-based drilling fluid and its application

A coalbed methane well and composition technology, applied in the field of drilling fluid additive composition and water-based drilling fluid, can solve the problems of undeveloped solid-free brine drilling fluid, pollution, clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

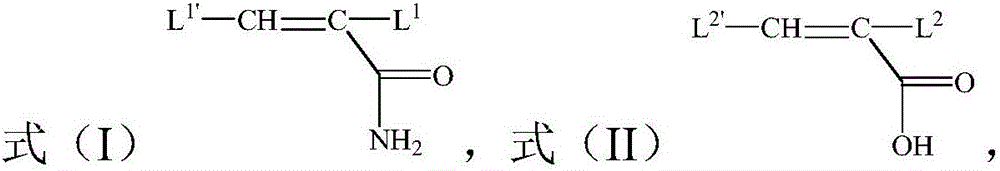

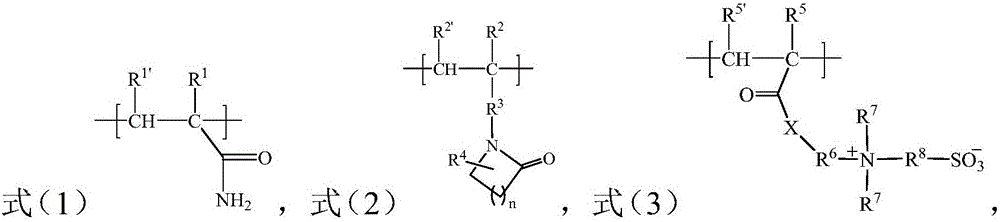

[0038] According to the present invention, the copolymer as the viscosity-increasing and shear-increasing agent can be prepared by conventional methods in the art, as long as it can be coordinated with other components of the composition of the present invention, it can play a better role in brine drilling fluid. Viscosity increasing and cutting effect, suitable for the drilling of coalbed methane wells. Preferably, the preparation method of the copolymer as the viscosity increasing and cutting agent comprises:

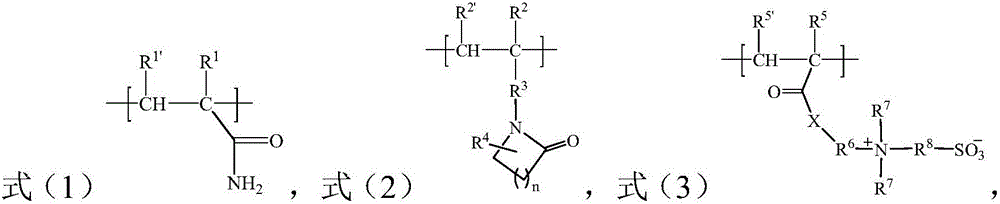

[0039] In an aqueous solvent, in the presence of a free radical initiator and a chain transfer agent, the compound shown in formula (1'), the compound shown in formula (2') and the compound shown in formula (3') undergo free radical Polymerization reaction, where,

[0040]

[0041] Wherein, the substituents involved in the monomers in the above method are as described above, and will not be repeated here. The compound represented by formula (1'), the compound rep...

preparation example 1

[0125] (1) 40g of microcrystalline cellulose (purchased from Hubei Sinomaterials Chemical Co., Ltd., the average particle size of the particles is 20 μm) is added into 700mL of sulfuric acid aqueous solution with a concentration of 64% by weight, and at 45°C at 250 rpm Stir at high speed for 3 hours;

[0126] (2) Add 3L of deionized water to the mixture obtained in step (1) to terminate the hydrolysis reaction of microcrystalline cellulose; centrifuge the obtained suspension for 20min at 11000r / min, then wash the solid obtained by centrifugation with deionized water Wash several times until the pH value of the supernatant obtained by centrifugation is 7; dry the washed solid at 105°C for 12 hours to obtain 35.28g of nanocrystalline cellulose, which is the fluid loss reducer N1, with a yield of 88.2 %. The average particle diameter of the product nanocrystalline cellulose measured by a transmission electron microscope (TEM) is 239 nm, and the nanocrystalline cellulose is rod-s...

preparation example 2

[0130] 1 mol total amount of methacrylamide, N-vinylpyrrolidone and [3-(methacrylamido) propyl] dimethyl (3-thiopropyl) ammonium hydroxide (molar ratio is 20:4 : 1) was added into 500mL of water, stirred and mixed for 30min at 200rpm and 30°C; then, 0.01mmol of disodium edetate, 0.14mmol of azobisisobutylamidine hydrochloride and 0.15 Mmol of sodium formate, and nitrogen for 20 minutes to remove oxygen; then carry out polymerization reaction at 50 ° C for 10 h; dry the polymer product at 80 ° C for 3 h, and pulverize to obtain a copolymer, which is the cutting agent A2. The weight-average molecular weight of this polymkeric substance is 3,200,000g / mol, and molecular weight distribution coefficient is 2.2, through infrared, nuclear magnetic resonance proton spectrum and carbon spectrum analysis detection, the structural unit (R) shown in formula (1) 1 is methyl, R 1' is H), the structural unit (R) shown in formula (2) 4 , R 2 and R 2' for H, R 3 An alkylene group selected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com