Preparation method of biological mimetic tissue adhesive

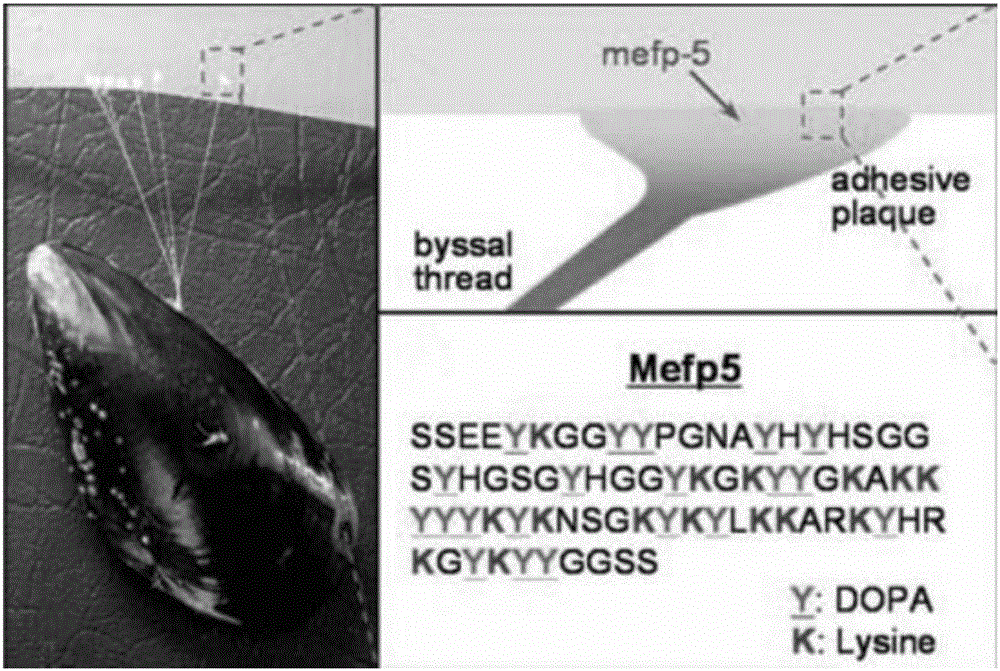

A tissue adhesive and bioadhesive technology, applied in the field of medical biomaterials, can solve the problems of cumbersome preparation process and poor biocompatibility, and achieve the effect of simple purification process, good adhesion performance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

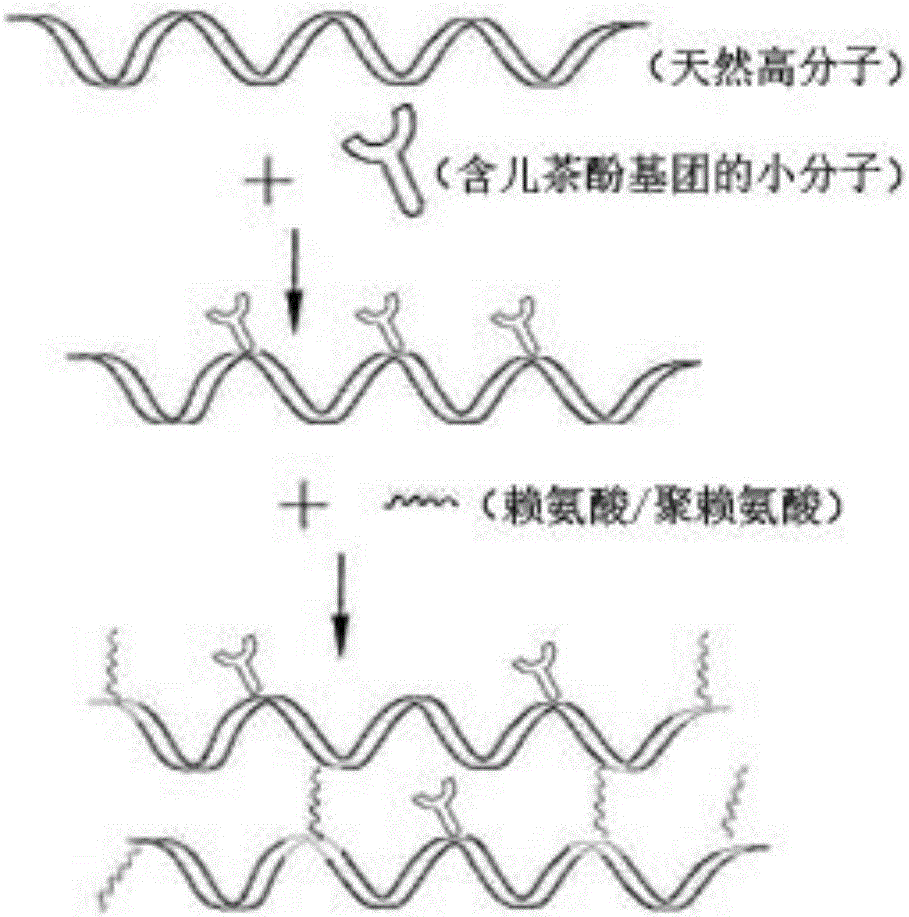

Method used

Image

Examples

Embodiment 1

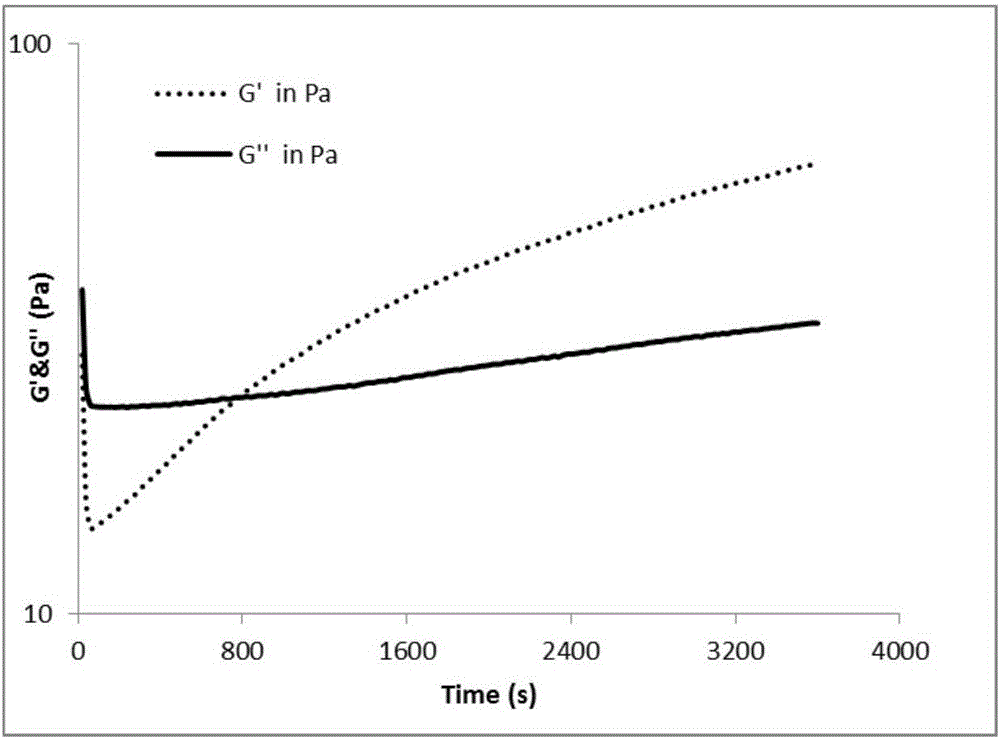

[0027] Dissolve 0.5g of sodium hyaluronate dry powder (molecular weight: 2,000,000DA) in 25mL of water, adjust the pH value to 5, then add 0.25g of dopamine hydrochloride and 0.5g of DMTMM, fill with nitrogen to deoxygenate and stir for 24 hours in the dark. . Weigh 0.034g of polylysine, and add 0.0986g of DMTMM into the above mixed system, and react for 6h under the condition of protecting from light by filling with nitrogen gas for deoxygenation. Dialyzed against PBS buffer solution with pH=5 for 2 days (molecular weight cut-off 10000), then dialyzed with PBS buffer solution with pH=7.2 for 2 days (molecular weight cut-off 10000), freeze-dried to obtain sample A, ready for use.

[0028] Dissolve 0.1 g of sample A in 5 mL of PBS solution. After the dissolution is complete, add 50 uL of 3% sodium periodate solution, mix quickly, and obtain a bioadhesive at room temperature.

Embodiment 2

[0030] Dissolve 0.5g of sodium hyaluronate dry powder (molecular weight: 310,000DA) in 25mL of water, adjust the pH to 5, then add 0.5g of dopamine hydrochloride and 0.5g of DMTMM, fill with nitrogen to deoxygenate and stir for 48 hours in the dark. . Weigh 0.034g of polylysine, and add 0.0986g of DMTMM into the above mixed system, and react for 6h under the condition of protecting from light by filling with nitrogen gas for deoxygenation. Dialyzed against PBS buffer with pH=5 for 2 days (molecular weight cut-off 10000), then dialyzed against PBS buffer with pH=7.2 for 2 days (molecular weight cut-off 10000), freeze-dried to obtain sample A, ready for use.

[0031] Dissolve 0.1 g of sample A in 1 mL of PBS solution. After the dissolution is complete, add 60 uL of 5% sodium periodate solution, mix quickly, and obtain a bioadhesive at room temperature.

Embodiment 3

[0033]Dissolve 0.6g of sodium hyaluronate dry powder (molecular weight: 710,000DA) in 25mL of water, adjust the pH to 5, then add 0.5g of dopamine hydrochloride and 1g of DMTMM, inflate with nitrogen to deoxygenate and stir for 24 hours in the dark. Weigh 0.034g of polylysine, and add 0.0986g of DMTMM into the above mixed system, and react for 6h under the condition of protecting from light by filling with nitrogen gas for deoxygenation. Dialyzed against PBS buffer with pH=5 for 2 days (molecular weight cut-off 10000), then dialyzed with PBS buffer with pH=7.2 for 2 days (molecular weight cut-off 10000), freeze-dried to obtain sample A, ready for use.

[0034] Dissolve 0.1 g of sample A in 2.5 mL of PBS solution. After the dissolution is complete, add 80 uL of 3% sodium periodate solution, mix quickly, and obtain a bioadhesive at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com