Covalent organic skeleton material-doped alcohol perm-selective membrane and preparation method thereof

A covalent organic framework and alcohol-preferred technology, applied in the field of membrane separation, can solve problems such as particle gap defects, affecting membrane performance, interface defects, etc., and achieve high flux, low density, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In a second aspect, an embodiment of the present invention provides a method for preparing the above-mentioned composite membrane, including:

[0042] Step a. Dissolve a certain amount of high molecular polymer into the solvent, stir evenly, add a certain amount of covalent organic framework material, and ultrasonically disperse it evenly; then add a certain amount of high molecular polymer crosslinking agent and catalyst , prepared as a covalent organic framework material / polymer blend membrane solution;

[0043] Step b. Immerse the pretreated porous base membrane in the covalent organic framework material / polymer blended membrane liquid, take it out after standing for a period of time, and fix it on the membrane stage, so that it can be The film carrier rotates at a constant speed; while rotating, the surface temperature of the basement film is 50-80°C, and the volatilization of the solvent on the surface of the basement film is accelerated;

[0044] Step c. Perform ...

Embodiment 1

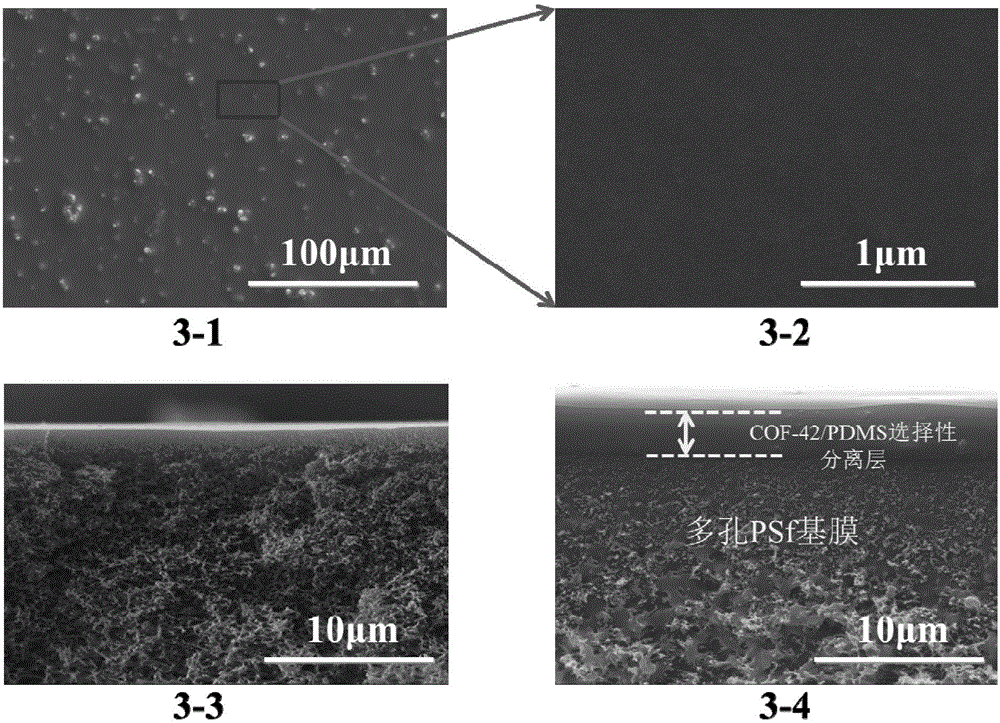

[0058] The porous base membrane is polysulfone (PSf) flat-plate ultrafiltration membrane, the molecular weight cut-off is 20000, the high molecular polymer used is PDMS (viscosity is 20000mPa s), the solvent is n-heptane, and the high-temperature baking lamp selected is Yuba heating lamp .

[0059] Preparation method and steps:

[0060] Step a. Dissolve 10wt.% PDMS into 100mL n-heptane, stir for 1 hour and then add covalent organic framework material COF-42. The loading capacity of COF-42 is 0.25wt.% of the polymer. Ultrasound for 30 minutes to make it fully mixed Evenly, then add 1wt.% ethyl orthosilicate and 0.05wt.% dibutyltin dilaurate, continue to stir for 0.5h, and prepare a COF-42 / PDMS mixed membrane solution;

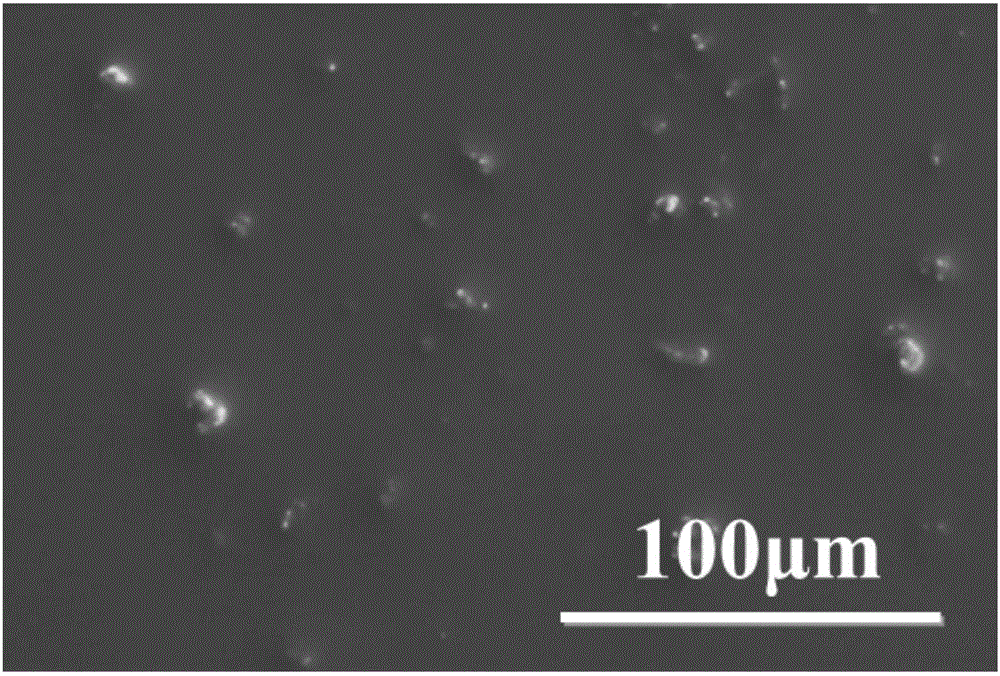

[0061] Step b. Under the condition that the ambient humidity is 20% lower, cut the pretreated PSf base film into a disc with a diameter of 20 cm and immerse it in the COF-42 / PDMS mixed film solution described in step a), take it out after standing for 1 min, an...

Embodiment 2

[0067] The porous base membrane is polysulfone (PSf) flat-plate ultrafiltration membrane, the molecular weight cut-off is 20000, the high molecular polymer used is PDMS (viscosity is 20000mPa s), the solvent is n-heptane, and the high-temperature baking lamp selected is Yuba heating lamp .

[0068] Preparation method and steps:

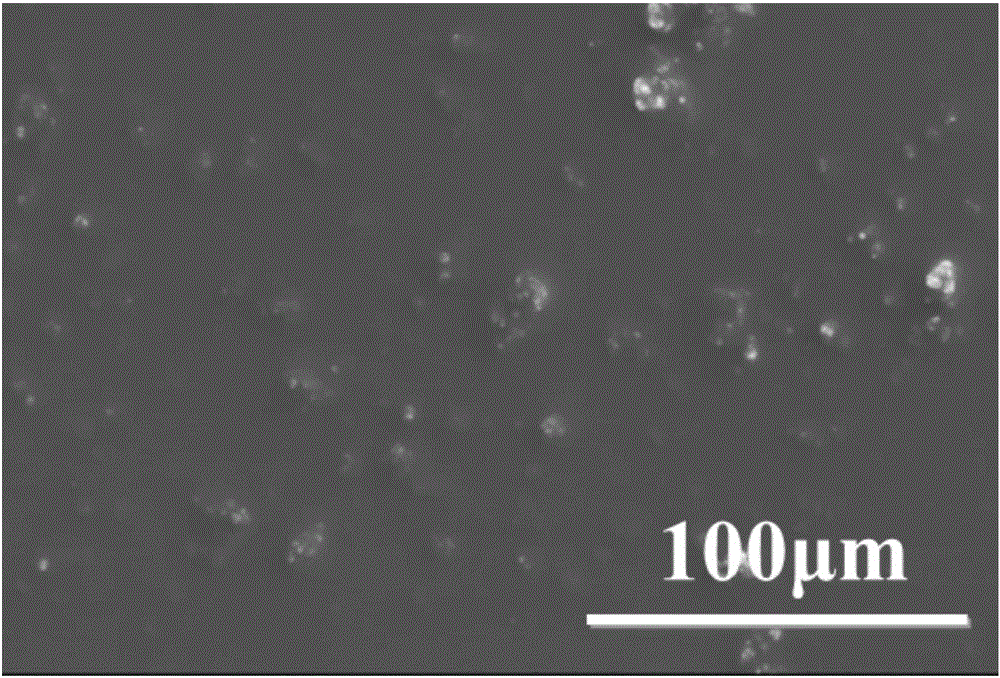

[0069] Step a. Dissolve 10wt.% PDMS into 100mL n-heptane, stir for 1 hour and then add covalent organic framework material COF-42. The loading of COF-42 is 0.5wt.% of the polymer, and ultrasonically mix for 30 minutes. Evenly, then add 1wt.% ethyl orthosilicate and 0.05wt.% dibutyltin dilaurate, continue to stir for 0.5h, and prepare a COF-42 / PDMS mixed membrane solution;

[0070] Step b. Under the condition that the ambient humidity is 20% lower, cut the pretreated PSf base film into a disc with a diameter of 20 cm and immerse it in the COF-42 / PDMS mixed film solution described in step a), take it out after standing for 1 min, and Fix it on a vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com