Organic fertilizer for cultivation of longan

A technology for organic fertilizers and longan, applied in the directions of organic fertilizers, organic fertilizer preparation, inorganic fertilizers, etc., can solve the problems of different planting methods and different yields from planting, so as to reduce production costs, enhance the ability to maintain and supply fertilizer and buffer Ability, the effect of facilitating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

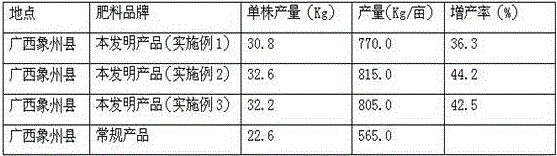

Examples

Embodiment 1

[0037] An organic fertilizer for longan cultivation, which is made of the following raw materials in parts by weight: 35 parts of methane fermentation residue; 25 parts of starch residue; 10 parts of bran; 3 parts of edible fungus residue; 5 parts of molasses alcohol waste liquid dry powder; 130 parts of urea; 100 parts of potassium chloride; 50 parts of potassium magnesium fertilizer; 120 parts of superphosphate; 20 parts of sugar factory filter mud; 4 parts of calcium sulfonate; 10 parts of ammonium humate; 3 parts of urea iron humate.

[0038] The preparation method of the humic acid urea iron is as follows: fully dissolve urea in water to obtain a solution, heat to maintain the temperature between 75-80°C, adjust the pH value to 6-7, and then follow the steps of urea:organic iron complex : The molar ratio of humic acid is 4-6: 1-1.3: 1-1.2. Add organic iron element complex to the solution first, react for 1-1.5 hours, then add humic acid for reaction 1-1.5 Hours, the reac...

Embodiment 2

[0046] An organic fertilizer for longan cultivation, which is made of the following raw materials in parts by weight: 38 parts of methane fermentation residue; 28 parts of starch residue; 12 parts of bran; 4 parts of edible fungus residue; 8 parts of molasses alcohol waste liquid dry powder; 140 parts of urea; 125 parts of potassium chloride; 60 parts of potassium magnesium fertilizer; 140 parts of superphosphate; 23 parts of sugar factory filter mud; 5 parts of calcium sulfonate; 12 parts of ammonium humate; 4 parts of urea humate.

[0047] The preparation method of the humic acid urea iron is as follows: fully dissolve urea in water to obtain a solution, heat to maintain the temperature between 75-80°C, adjust the pH value to 6-7, and then follow the steps of urea:organic iron complex : The molar ratio of humic acid is 4-6: 1-1.3: 1-1.2. Add organic iron element complex to the solution first, react for 1-1.5 hours, then add humic acid for reaction 1-1.5 Hours, the reaction ...

Embodiment 3

[0055] An organic fertilizer for longan cultivation, which is made from the following raw materials in parts by weight: 40 parts of biogas fermentation residue; 30 parts of starch residue; 15 parts of bran; 5 parts of edible fungus residue; 10 parts of molasses alcohol waste liquid dry powder; 150 parts of urea; 150 parts of potassium chloride; 70 parts of potassium magnesium fertilizer; 160 parts of superphosphate; 25 parts of sugar factory filter mud; 6 parts of calcium sulfonate; 15 parts of ammonium humate; 5 parts of urea iron humate.

[0056] The preparation method of the humic acid urea iron is as follows: fully dissolve urea in water to obtain a solution, heat to maintain the temperature between 75-80°C, adjust the pH value to 6-7, and then follow the steps of urea:organic iron complex : The molar ratio of humic acid is 4-6: 1-1.3: 1-1.2. Add organic iron element complex to the solution first, react for 1-1.5 hours, then add humic acid for reaction 1-1.5 Hours, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com