Novel foamed plastic

A foamed plastic and a new type of technology, applied in the field of plastic preparation technology and environmental protection, can solve the problems of poor sound insulation effect and weak degradability, and achieve the effects of good sound insulation effect, slow decomposition speed and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the novel foam plastic includes the following steps:

[0058] S1: Mix polyether polyol, vinyl tris (β-methoxyethoxy) silane, glycerol triacetate, and polyester resin, and stir at a temperature of 112-118°C and a rotation speed of 300-400r / min 8-12min, the mixture I is prepared;

[0059] S2: Under the protection of nitrogen, add montmorillonite, aluminum hydroxide, abaca fiber, polyamide fiber, glass fiber, polyethylene wax, maleic anhydride, dibutyltin dilaurate to the mixture I prepared in step 1 Ethylene-ethyl acrylate copolymer, isopentane, potassium isozinate, polyvinyl acetate emulsion, dimethicone, triethanolamine, initiator, crosslinking agent, catalyst, accelerator, plasticizer, toughening agent, Foaming agent, foaming regulator, and foam stabilizer are stirred for 1.5-2.5h at a microwave power of 140-220W, a temperature of 92-95℃, and a rotation speed of 200-300r / min to prepare mixture II;

[0060] S3: Add soybean protein powder, modified s...

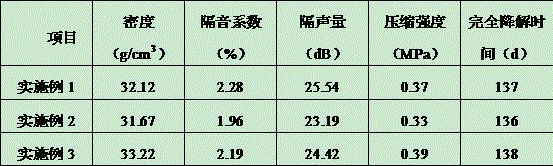

Embodiment 1

[0072] A new type of foam plastic, in parts by weight, including the following raw materials: 135 parts of polyether polyol, 30 parts of vinyl tris(β-methoxyethoxy) silane, 24 parts of glycerol triacetate, polyester resin 23 parts, 14 parts soy protein powder, 13 parts modified starch, 6 parts montmorillonite, 3 parts aluminum hydroxide, 7 parts abaca fiber, 10 parts polyamide fiber, 6 parts glass fiber, 10 parts polyethylene wax, horse 2 parts of acetic anhydride, 2 parts of dibutyltin dilaurate, 2 parts of ethylene-ethyl acrylate copolymer, 3 parts of isopentane, 3 parts of potassium isozinate, 5 parts of polyvinyl acetate emulsion, 4 parts of dimethyl silicone oil, 1 part of triethanolamine, 0.6 part of initiator, 0.4 part of crosslinking agent, 0.2 part of catalyst, 0.1 part of accelerator, 0.6 part of plasticizer, 0.5 part of toughening agent, 0.4 part of foaming agent, 0.1 part of foaming regulator, 0.3 parts of foam stabilizer, 1 part of antibacterial agent, 1.8 parts of...

Embodiment 2

[0101] A new type of foam plastic, in parts by weight, including the following raw materials: 122 parts of polyether polyol, 21 parts of vinyl tris(β-methoxyethoxy) silane, 17 parts of glycerol triacetate, polyester resin 18 parts, 12 parts soy protein powder, 10 parts modified starch, 4 parts montmorillonite, 2 parts aluminum hydroxide, 4 parts abaca fiber, 7 parts polyamide fiber, 3 parts glass fiber, 8 parts polyethylene wax, horse 2 parts of acetic anhydride, 1 part of dibutyltin dilaurate, 2 parts of ethylene-ethyl acrylate copolymer, 1 part of isopentane, 2 parts of potassium isozinate, 3 parts of polyvinyl acetate emulsion, 2 parts of dimethyl silicone oil, 1 part of triethanolamine, 0.4 part of initiator, 0.3 part of crosslinking agent, 0.1 part of catalyst, 0.1 part of accelerator, 0.3 part of plasticizer, 0.3 part of toughening agent, 0.3 part of foaming agent, 0.1 part of foaming regulator, 0.2 part of foam stabilizer, 0.7 part of antibacterial agent, 1.2 part of deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sound insulation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com