High-strength anti-corrosive steel product and preparation method therefor and application thereof

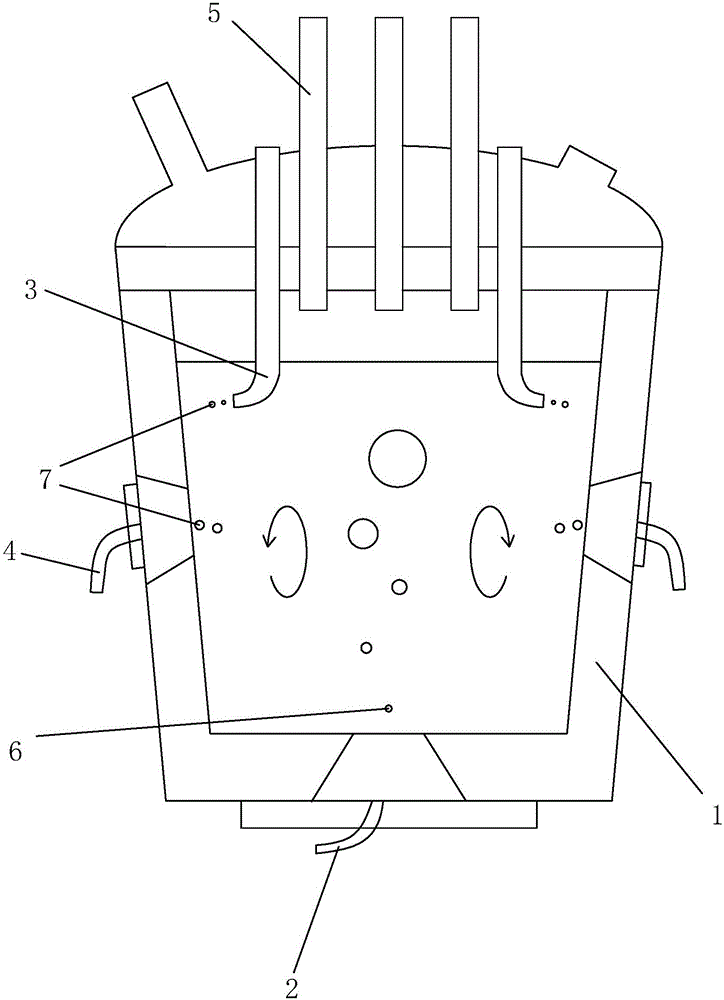

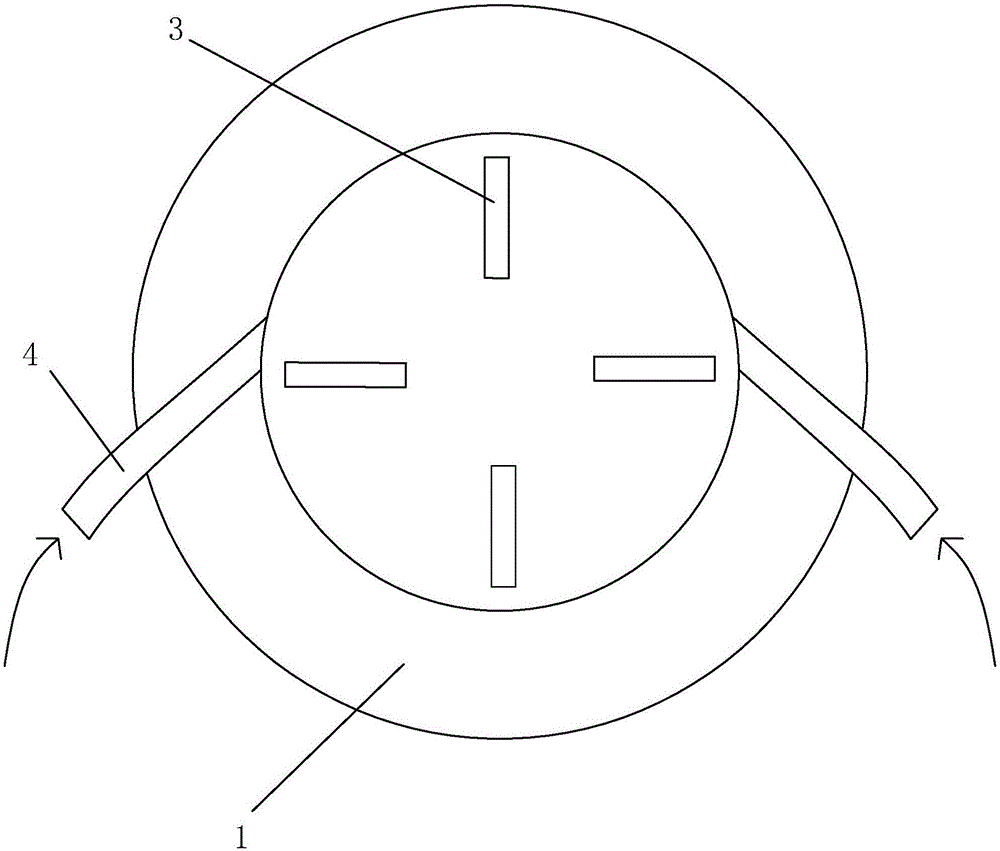

A steel, high-strength technology, applied in the field of high-strength anti-corrosion steel and its preparation, can solve the problems of unsuitable use, lack of corrosion resistance, etc., to achieve low processing cost, enhanced decarburization and desulfurization effect, and the effect of promoting turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

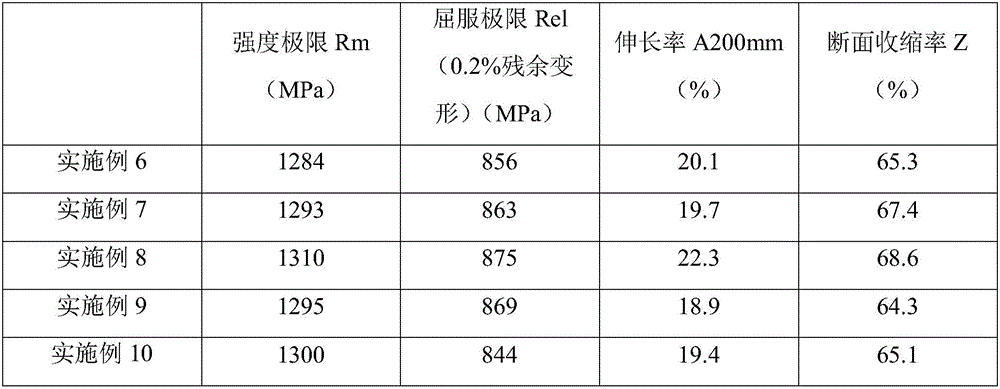

Examples

Embodiment 1

[0057] Step1: According to parts by weight, weigh 65 parts of lime, 10 parts of sodium oxide, 1 part of ferrous oxide, 0.4 parts of manganese dioxide, 5 parts of titanium dioxide, 5 parts of magnesium oxide, 1.5 parts of aluminum nitride, and 0.6 parts of tungsten carbide, and add Grind and mix evenly in the roller sand mixer, and the particle size of the obtained mixture is 0.9mm;

[0058] Step2: Add the mixture into the symmetrical briquetting machine, extrude pellets with a diameter of 15mm under the condition of a symmetrical briquetting machine pressure of 15MPa, dry the pellets naturally for 48 hours, and dry the pellets at a temperature of 300°C Lower roasting for 0.5h to obtain a pellet-shaped slagging agent. The water content of the slagging agent is 4%wt.

Embodiment 2

[0060] Step1: In parts by weight, weigh 69 parts of lime, 5 parts of sodium oxide, 0.5 parts of ferrous oxide, 0.3 parts of manganese dioxide, 8 parts of titanium dioxide, 2.5 parts of magnesium oxide, 1.3 parts of aluminum nitride, and 1.4 parts of tungsten carbide, and add Grind and mix evenly in the roller sand mixer, and the particle size of the obtained mixture is 0.8mm;

[0061] Step2: Add the mixture into the symmetrical briquetting machine, extrude pellets with a diameter of 15mm under the condition of a symmetrical briquetting machine pressure of 15MPa, dry the pellets naturally for 48 hours, and dry the pellets at a temperature of 300°C Lower roasting for 0.5h to obtain a pellet-shaped slagging agent. The water content of the slagging agent is 5%wt.

Embodiment 3

[0063] Step1: In parts by weight, weigh 73 parts of lime, 6 parts of sodium oxide, 0.3 parts of ferrous oxide, 0.8 parts of manganese dioxide, 12 parts of titanium dioxide, 2 parts of magnesium oxide, 1 part of aluminum nitride, and 1.2 parts of tungsten carbide, and add Grind and mix evenly in the roller sand mixer, and the particle size of the obtained mixture is 0.9mm;

[0064] Step2: Add the mixture into the symmetrical briquetting machine, extrude pellets with a diameter of 15mm under the condition of a symmetrical briquetting machine pressure of 15MPa, dry the pellets naturally for 48 hours, and dry the pellets at a temperature of 300°C Lower roasting for 0.5h to obtain a pellet-shaped slagging agent. The water content of the slagging agent is 3%wt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com