Special water purifying agent for chloroprene rubber production and wastewater treatment method

A chloroprene rubber and wastewater treatment technology, which is applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve unfavorable easy-to-treat wastewater recycling, chemical treatment method pollution, and unsatisfactory results and other problems, to achieve the effect of strong practicability, cheap raw materials, and simple sewage treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

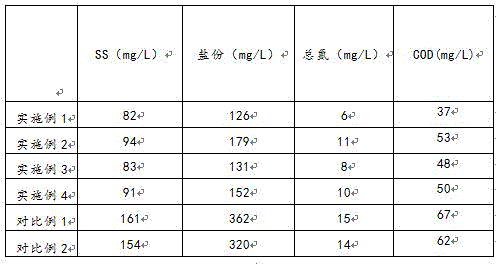

Examples

Embodiment 1

[0022] 1) Add alkaline white mud to the wastewater, stir and react at 35-70°C for 20 minutes, let it settle and filter it, then add water purifying agent in an amount of 35 mg / L. The raw material composition of water purifying agent is: caustic 30 parts of alkali, 25 parts of polydimethyldiallylammonium chloride, 15 parts of polyethyleneimine, 10 parts of bentonite, 10 parts of polyoxysuccinic acid, 5 parts of sericite powder, 5 parts of carboxyacetic acid, water-soluble humic acid 3 parts of sodium bicarbonate, 3 parts of tetraphenylporphyrin iron, 2 parts of cottonseed hulls, stirred for 30 minutes at a speed of 15 rpm, left standstill for 3 hours, and the waste water was stratified into supernatant and solid precipitation;

[0023] 2) Send the supernatant to the deep oxidation tower, adjust the pH of the supernatant to 2, aerate evenly, add oxidants, carry out deep oxidation, and measure the water quality indicators in real time. When the concentration of heavy metals in the...

Embodiment 2

[0030] 1) Add alkaline white mud to the waste water, stir and react at 55°C for 35 minutes, let it settle and filter it, then add water purifying agent in an amount of 35mg / L, the raw material composition of water purifying agent is: caustic alkali 33 28 parts of polydimethyldiallyl ammonium chloride, 20 parts of polyethyleneimine, 15 parts of bentonite, 12 parts of polyoxysuccinic acid, 7 parts of sericite powder, 6 parts of carboxyacetic acid, water-soluble sodium humate 4 parts, 4 parts of tetraphenylporphyrin iron, 3 parts of cottonseed hulls, stirred at a speed of 25 rpm for 40 minutes, left to stand for 3.5 hours, and the waste water was stratified into supernatant and solid precipitation;

[0031] 2) Send the supernatant to the deep oxidation tower, adjust the pH of the supernatant to 2.5, aerate evenly, add oxidants, carry out deep oxidation, and measure the water quality indicators in real time. When the concentration of heavy metals in the water is less than 2.5mg / L, ...

Embodiment 3

[0038] 1) Add alkaline white mud to the waste water, stir and react at 70°C for 50 minutes, let it sit for precipitation and filter, then add water purifier in an amount of 35mg / L, the raw material composition of water purifier is: caustic alkali 35 30 parts of polydimethyldiallyl ammonium chloride, 25 parts of polyethyleneimine, 20 parts of bentonite, 15 parts of polyoxysuccinic acid, 10 parts of sericite powder, 8 parts of carboxyacetic acid, water-soluble sodium humate 5 parts, 5 parts of tetraphenylporphyrin iron, 3 parts of cottonseed hulls, stirred at a speed of 30 rpm for 50 minutes, left to stand for 4 hours, and the waste water was stratified into supernatant and solid precipitation;

[0039] 2) Send the supernatant to the deep oxidation tower, adjust the pH of the supernatant to 3, aerate evenly, add oxidants, carry out deep oxidation, and measure the water quality indicators in real time. When the concentration of heavy metals in the water is less than 2.5mg / L, cyani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com