Epsilon-polylysine high-yielding strain and epsilon-polylysine production method

A technology of polylysine and high-yielding strains, applied in the biological field, can solve the problems of large equipment investment, complex separation process and high cost, and achieve the effects of small equipment investment, low energy consumption and improved product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

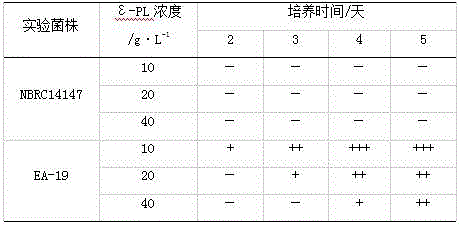

[0028] Example 1 Screening of high-yield strain EA-19

[0029] (1) The spores of Streptomyces albicans NBRC14147 were made into a spore suspension using tirs-maleic acid buffer, and the spore concentration was about 10 7 ~10 8 individual / mL.

[0030] (2) Take 5 mL of the spore suspension and add it to a Φ9 cm sterile plate; place the sterile plate in a UV mutagenesis box at a distance of 30 cm from a 15 W UV lamp for 30 s of ultraviolet irradiation mutagenesis.

[0031] (3) Take the sterile plate out of the UV mutagenesis chamber, then add nitrosoguanidine to the spore suspension in the sterile plate so that the final concentration of nitrosoguanidine is 0.8 mg / mL, and shake for 30 min in the dark ; terminate mutagenesis.

[0032] (4) After the mutagenesis is over, wash the cells and add 5 mL of dark culture overnight (the culture time is about 16 hours). Fermentation medium: glucose 50 g / L, yeast powder 5 g / L, ammonium sulfate 10 g / L, ferrous sulfate 0.03 g / L, zinc sulfat...

Embodiment 2

[0049] Example 2 High-yield strain EA-19 Fermentation Separation Coupling Production ε-Polylysine

[0050] (1) Inoculate the EA-19 spore suspension prepared in Example 1 into the liquid seed medium at a 2% inoculum amount, and incubate at 30 °C and 250 r / min for 24 h; obtain the EA-19 seed liquid. The composition of the seed medium is glycerol 20 g / L, yeast powder 5 g / L, ferrous sulfate 0.03 g / L, zinc sulfate 0.04 g / L, magnesium sulfate 0.5 g / L, dipotassium hydrogen phosphate 0.8 g / L, phosphoric acid Potassium dihydrogen 1.36g / L.

[0051] (2) Inoculate the EA-19 seed liquid into the fermentation medium according to the inoculum amount of 5%, the culture temperature is 30 ℃, the stirring speed is 400 200-500r / min, the ventilation ratio is 1:1 (V / V m), and the fermentation starts to cultivate. The fermentation medium is glucose 50 g / L, yeast powder 5 g / L, ammonium sulfate 10 g / L, ferrous sulfate 0.03 g / L, zinc sulfate 0.04 g / L, magnesium sulfate 0.5 g / L, dipotassium hydrogen p...

Embodiment 3

[0058] Example 3 High-yield strain EA-19 Fermentation separation coupled production of ε-polylysine

[0059] (1) Inoculate the EA-19 spore suspension prepared in Example 1 into the liquid seed medium at a 2% inoculation amount, and incubate at 30 °C and 250 r / min for 24 h; the EA-19 seed liquid was obtained. The composition of the seed medium is glycerol 20 g / L, yeast powder 5 g / L, ferrous sulfate 0.03 g / L, zinc sulfate 0.04 g / L, magnesium sulfate 0.5 g / L, dipotassium hydrogen phosphate 0.8 g / L, phosphoric acid Potassium dihydrogen 1.36g / L.

[0060] (2) Inoculate the obtained EA-19 seed liquid into the fermentation medium according to the inoculum amount of 5%. The culture temperature is 30 ℃, the stirring speed is 400 r / min, the ventilation ratio is 1:1 V / V·m, and the fermentation culture is started. The fermentation medium is glucose 50 g / L, yeast powder 5 g / L, ammonium sulfate 10 g / L, ferrous sulfate 0.03 g / L, zinc sulfate 0.04 g / L, magnesium sulfate 0.5 g / L, dipotassium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com