Method for treating papermaking white water by utilizing cutinase

A technology of cutinase and processing time, which is applied in the field of enzyme engineering, can solve the problems of high processing cost, downtime, paper quality, and large chemical consumption, and achieve the effects of improving production efficiency, mild reaction conditions, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

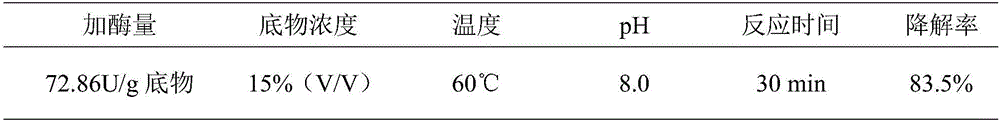

[0028] Example 1: Thermobifidafusca-derived cutinase hydrolysis of papermaking white water resinous deposits (glycerol trioleate) model

[0029] Weigh 15 mL of triolein (0.915 g / mL) and add it to 85 mL of Tris-HCl buffer solution at pH 8.0. After mixing evenly, take 10 mL and add 100 U of Thermobifidafusca-derived cutinase (Genbank accession number: AAZ54920), in a 60°C water bath After 30 minutes of accurate reaction in medium, take 5mL of reaction solution and add 5mL of 95% ethanol to terminate the reaction, and then use 0.05mol / L sodium hydroxide standard solution to titrate to pH 10.3 on the potentiometric titrator as the end point. According to the sodium hydroxide standard solution consumed by titration The volume of cutinase to judge the decomposition of triolein. Cutinase can decompose triolein to generate oleic acid. By titration, the more sodium hydroxide consumption is consumed, the more thorough the enzyme reaction is. The results are shown in the table As shown i...

Embodiment 2

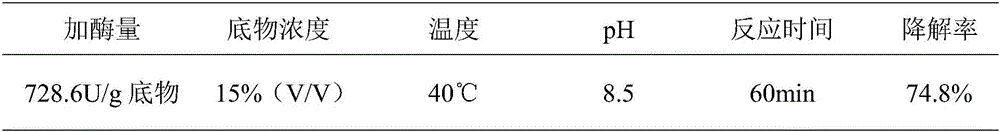

[0032] Example 2: Fusarium solani-derived cutinase hydrolyzes papermaking white water resinous deposits (glycerol trioleate) model

[0033] Weigh 15 mL of triolein and add it to 85 mL of Tris-HCl buffer solution at pH 8.5. After mixing evenly, take 10 mL and add 1000 U Fusarium solani-derived cutinase (Genbank accession number: AAA33334), and react in a 60°C water bath for 60 minutes Finally, take 5 mL of sample and add 5 mL of 95% ethanol to terminate the reaction, and then use 0.05 mol / L sodium hydroxide standard solution to titrate on a potentiometric titrator to pH 10.3 as the end point. According to the volume of sodium hydroxide standard solution consumed by titration, the decomposition of triolein by cutinase is judged. The results are shown in Table 2. When the amount of cutinase added to the reaction solution was 728.6U / g substrate, the degradation rate of triolein reached 74.8% after reacting at 40°C for 60 minutes.

Embodiment 3

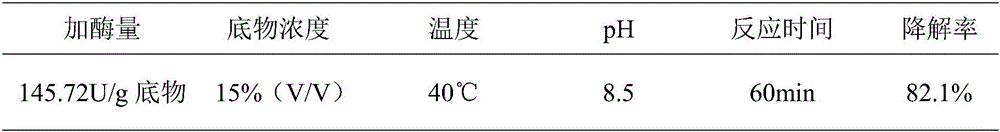

[0036] Example 3: Humicola Insolens-derived Cutinase Hydrolysis of Papermaking White Water Resin Deposits (Glyceryl Trioleate) Model

[0037] Weigh 15 mL of triolein and add it to 85 mL of Tris-HCl buffer solution at pH 8.5. After mixing evenly, take 10 mL and add 200 U of cutinase from Humicola Insolens (RCSB Protein data bank accession number: 4OYY), in a water bath at 40 °C After accurate reaction for 60 minutes, take 5 mL of sample and add 5 mL of 95% ethanol to terminate the reaction, and then use 0.05 mol / L sodium hydroxide standard solution to titrate to pH 10.3 on the potentiometric titrator as the end point. According to the volume of sodium hydroxide standard solution consumed by titration, the decomposition of triolein by cutinase is judged. The results are shown in Table 2. When the amount of cutinase added was 145.72U / g of the substrate reaction solution, the degradation rate of triolein reached 83.5% after reacting at 60°C for 60 minutes.

[0038] Table 2 Hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com