Nitrification aerobic granular sludge culture method and application

A technology of aerobic granular sludge and cultivation method, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., and can solve the problems of high cost, high cost of physical and chemical methods, secondary pollution, etc. , to achieve the effect of strong impact resistance, good settlement performance and high organic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: the cultivation of nitrifying aerobic granular sludge

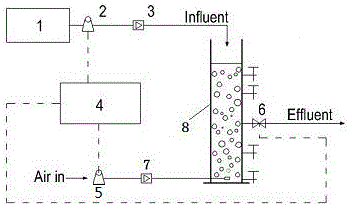

[0048] (1) Operation control of experimental device

[0049] The experimental setup of the SBR reactor is as follows: figure 1 shown. The SBR reactor has a total height of 100cm, an inner diameter of 7cm, and an effective volume of 2L. The drain is located at a distance of 26cm from the bottom of the reactor. The displacement is 1L, that is, the drainage ratio is 50%. There is an aeration head at the bottom of the reactor, the air is supplied by the air pump and the aeration volume is controlled by a rotameter, and the aeration volume is controlled at 0.1-0.3m 3 / h. Artificially prepared simulated wastewater is loaded into the water distribution tank, sucked by a small pump, and pumped into the SBR reactor from the upper water inlet. The drain is located in the middle of the reactor, and the drain is controlled by a solenoid valve. Each operation cycle of the SBR reactor is about 4 hours. The wat...

Embodiment 2

[0062] Embodiment 2: nitrifying aerobic granular sludge to waste water (COD / NH 4 + -N / TP) processing

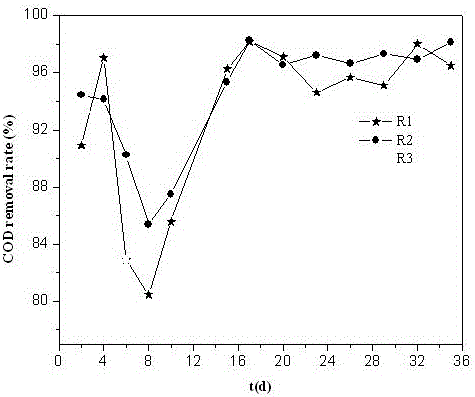

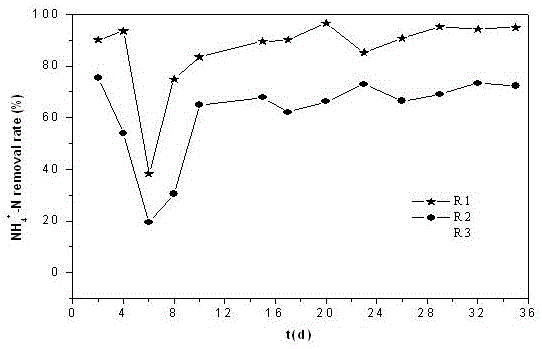

[0063] In the cultivation of aerobic granular sludge, the removal of pollutants during the operation of the reactor is shown in Figure 3. Since the inoculation sludge of the initial reactor is taken from the membrane bioreactor, it is the sludge domestication process in the early stage of cultivation to ensure the normal growth of the sludge. The initial influent COD concentration is 200mg / L, gradually increase the reactor influent concentration, and the influent COD concentration gradually increases from 200mg / L to 800mg / L and stabilizes there. After culturing for 35 days, the COD removal rate in the two reactors R1 and R2 was basically maintained at around 95%, which was similar to the COD removal rate of the sludge at the time of inoculation.

[0064] At the same time, it can be seen from Figure 3 that the granular sludge formed under different conditions of C / N ratio h...

Embodiment 3

[0066] Embodiment 3: nitrifying aerobic granular sludge to Pb 2+ Determination of optimal pH for adsorption

[0067] Weigh 0.1g of dry aerobic granular sludge and place it in eight 250mL stoppered Erlenmeyer flasks, add 100mL of actual wastewater, and adjust the pH values to 1.25 (stock solution), 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5, place the Erlenmeyer flask in a constant temperature shaking shaker, set the temperature and speed of the shaker at 25°C and 200r / min respectively, shake for 2.0h, and measure Pb after filtering with a 0.45μm filter membrane 2+ concentration value. The scanning of aerobic granular sludge before and after adsorption is shown in Fig. 4.

[0068] When the pH value is 3.5, the best adsorption effect can be achieved, and the corresponding removal rate is 97.61%, that is, the raw water quality contains Pb 2+ When the concentration is 23.8mg / L, the effluent concentration is 0.57mg / L, and the corresponding adsorption capacity is 23.23mg / g. 2+The adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com