Modified silicon soil lake mud building material and preparation method

A technology for modifying silicon and soil quality, applied in the field of building materials, can solve the problems of easy blocking of diatomite pores, reduce adsorption capacity, secondary dust pollution, etc., achieve synergy of stability, reduce the risk of cracking, and reduce ecological the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

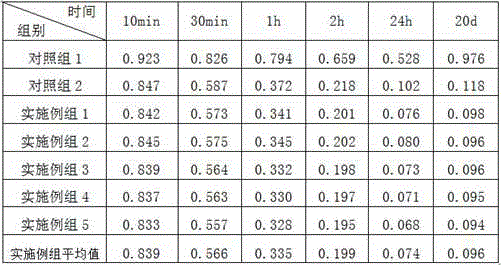

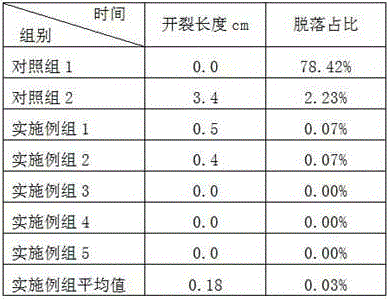

Examples

Embodiment 1

[0027] A modified siliceous lake mud building material, comprising the following components in parts by weight: 23 parts of distilled water, 45 parts of modified siliceous lake mud powder, 3 parts of activated carbon powder for injection, 2 parts of modified mineral water-retaining thickener, rutile 15 parts of nano titanium dioxide, 2 parts of photocatalyst, 10 parts of heavy calcium carbonate powder, 5 parts of quicklime powder, 0.1 part of modified acrylate emulsion, 4 parts of medical stone powder, 0.5 part of hydroxypropyl methylcellulose, 3 parts of pigment part, nano-TiO2 modified chitosan antibacterial and antifungal agent 0.1 part.

[0028] A preparation method of modified siliceous lake mud building material, comprising the following steps: loading the siliceous lake mud into a mixer, adding 5 parts by weight of PAS inorganic flocculant, stirring at 100 r / min for 60 s, standing for 40 minutes, and discharging the supernatant liquid Then put it into a rotary kiln, cal...

Embodiment 2

[0030] A modified siliceous lake mud building material, comprising the following components in parts by weight: 52 parts of distilled water, 10 parts of modified siliceous lake mud powder, 8 parts of activated carbon powder for injection, 25 parts of modified mineral water-retaining thickener, rutile 1 part of nano titanium dioxide, 12 parts of photocatalyst, 0.1 part of heavy calcium carbonate powder, 0.1 part of quicklime powder, 10 parts of modified acrylate emulsion, 0.1 part of medical stone powder, 5 parts of hydroxypropyl methylcellulose, 0.1 part of pigment parts, 3 parts of nano-TiO2 modified chitosan antibacterial and antifungal agent.

[0031] A method for preparing a modified siliceous lake mud building material, comprising the following steps: putting the siliceous lake mud into a mixer, adding 3 parts by weight of PAS inorganic flocculant, stirring at 200r / min for 30s, standing for 60min, and discharging the supernatant liquid Then put it into a rotary kiln, calc...

Embodiment 3

[0033] A modified siliceous lake mud building material, comprising the following components in parts by weight: 35 parts of distilled water, 30 parts of modified siliceous lake mud powder, 4 parts of activated carbon powder for injection, 5 parts of modified mineral water-retaining thickener, rutile 8 parts of nano titanium dioxide, 5 parts of photocatalyst, 5 parts of heavy calcium carbonate powder, 3 parts of quicklime powder, 1.5 parts of modified acrylate emulsion, 2 parts of medical stone powder, 1 part of hydroxypropyl methylcellulose, 1 part of pigment part, nano-TiO2 modified chitosan antibacterial and antifungal agent 0.5 part.

[0034] A method for preparing modified siliceous lake mud building materials, comprising the following steps: loading the siliceous lake mud into a mixer, adding 3.5 parts by weight of PAS inorganic flocculant, stirring at 180r / min for 40s, standing for 55min, and discharging the supernatant liquid Then put it into a rotary kiln, calcined at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com