Low-energy-consumption electrochemical hydrogen production system based on difunctional nano array electrode

A nano-array, bi-functional catalysis technology, applied in electrodes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low energy consumption and limited, and achieve broad application prospects, low energy consumption electrochemical hydrogen production, The effect of efficient electrochemical hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Add 36 mL of distilled water to the polytetrafluoroethylene liner, that is, add 1.45 g of nickel nitrate and 1.40 g of hexamethylene tetramine, and stir until the solid is completely dissolved to form a transparent solution.

[0021] Step 2: Put the nickel mesh into the lining of the reaction kettle in step 1, seal the PTFE lining into the stainless steel mold, place it in a constant temperature drying oven under closed conditions, and heat and react at 100° C. for 10 hours.

[0022] Step 3: After the reaction is completed, cool down to room temperature with the furnace, then take out the nickel mesh, wash with distilled water and anhydrous ethanol in turn, and arrange the washed carbon fibers in a vacuum drying box and vacuum dry at 40 ° C for 24 hours to obtain Ni(OH) 2 Nanosheet arrays.

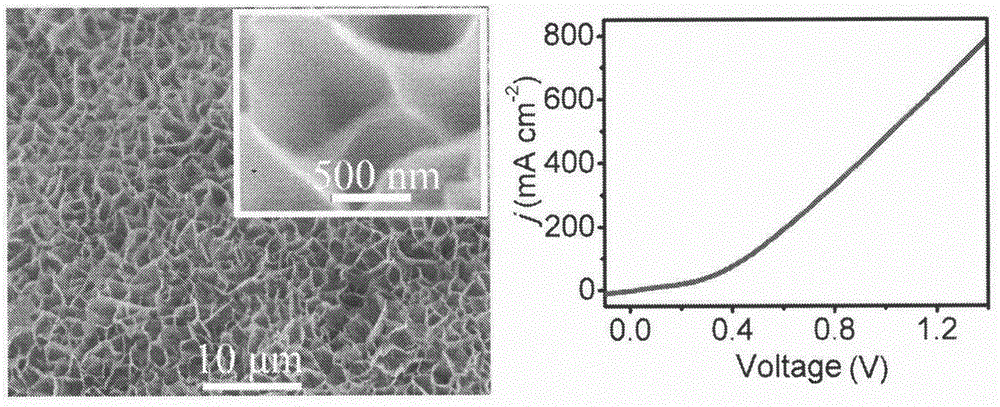

[0023] Step 4: Place the precursor obtained in Step 3 in a tube furnace and add sodium hypophosphite, and react at 300°C for 2h in an argon atmosphere to obtain Ni 2 P nan...

Embodiment 2

[0026] Step 1: Add 35 mL of distilled water to the polytetrafluoroethylene liner, add 0.4 g of ferric chloride hexahydrate and 0.24 g of sodium sulfate and stir until the solid is completely dissolved.

[0027] Step 2: put the carbon cloth into the inner lining of the reaction kettle in step 1, and seal the PTFE lining into the stainless steel mold, place it in a constant temperature drying oven under closed conditions, and react at 120° C. for 6 hours.

[0028] Step 3: After the reaction is completed, cool down to room temperature with the furnace, then take out the carbon cloth, wash it, and arrange the washed carbon in a vacuum drying box and vacuum dry it at 40 ° C for 24 hours to obtain Fe 2 O 3 Nanosheet arrays.

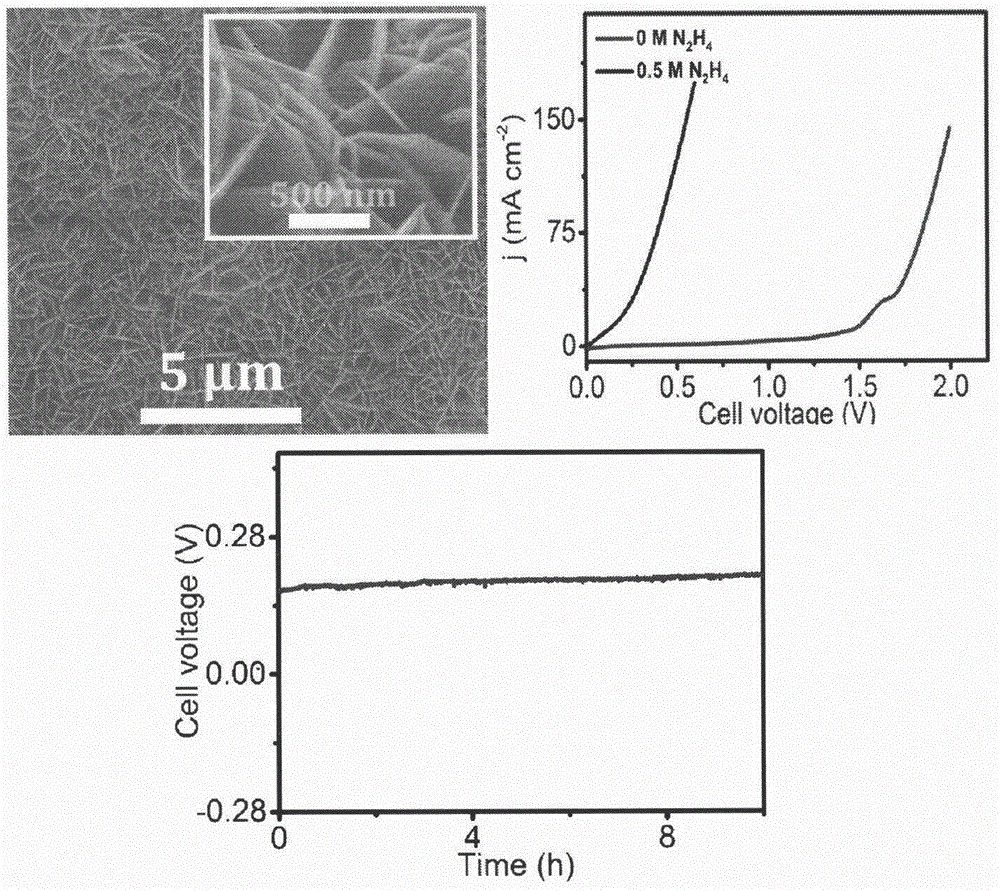

[0029] Step 4: Prepare Fe from Step 3 2 O 3 The nanosheet array was placed in a tube furnace and potassium hypophosphite was added, and reacted at 300 °C for 2 h in an argon atmosphere to obtain FeP nanosheet array ( figure 2 ).

[0030] Step 5: Using two...

Embodiment 3

[0032] Step 1: add 40 mL of distilled water to the polytetrafluoroethylene lining, add 1 mmol of zinc nitrate, 2 mmol of cobalt nitrate, 0.074 g of ammonium fluoride and 0.3 g of urea, stir and dissolve to form a transparent solution.

[0033] Step 2: Put the conductive glass sheet into the lining of the reaction kettle in step 1, and seal the PTFE lining into the stainless steel mold, place it in a constant temperature drying oven under closed conditions, and heat it at 120 ° C for 6 hours. .

[0034] Step 3: After the reaction is completed, the glass sheet is taken out, washed, and the washed glass sheet is placed in a vacuum drying oven and dried at 40 ° C for 24 h to obtain a zinc-cobalt hydroxide array structure, and then dried in air for 400 Annealed at ℃ for 2 hours to obtain ZnCo 2 O 4 array of nanowires.

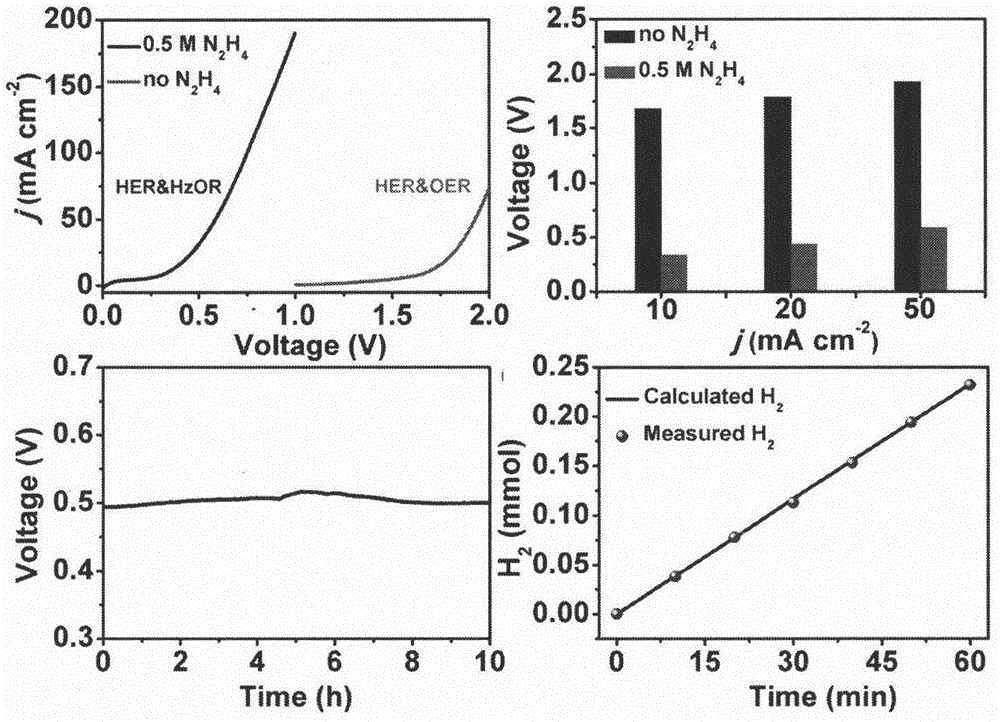

[0035] Step 4: Prepare ZnCo from Step 3 2 O 4 The nanowire array was placed in a tube furnace and potassium hypophosphite was added, and reacted at 320° C. for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com