Preparation and chemical modification method of polymer graphene composite chromatographic filling material

A graphene composite and chromatographic packing technology is applied in the field of preparation and chemical modification of polymer graphene composite high-performance liquid chromatography columns, and can solve the problems of poor mechanical strength of stationary phase, low column efficiency of chromatographic columns, low exchange capacity, etc. , to achieve the effect of wide acid-base range, good chemical stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

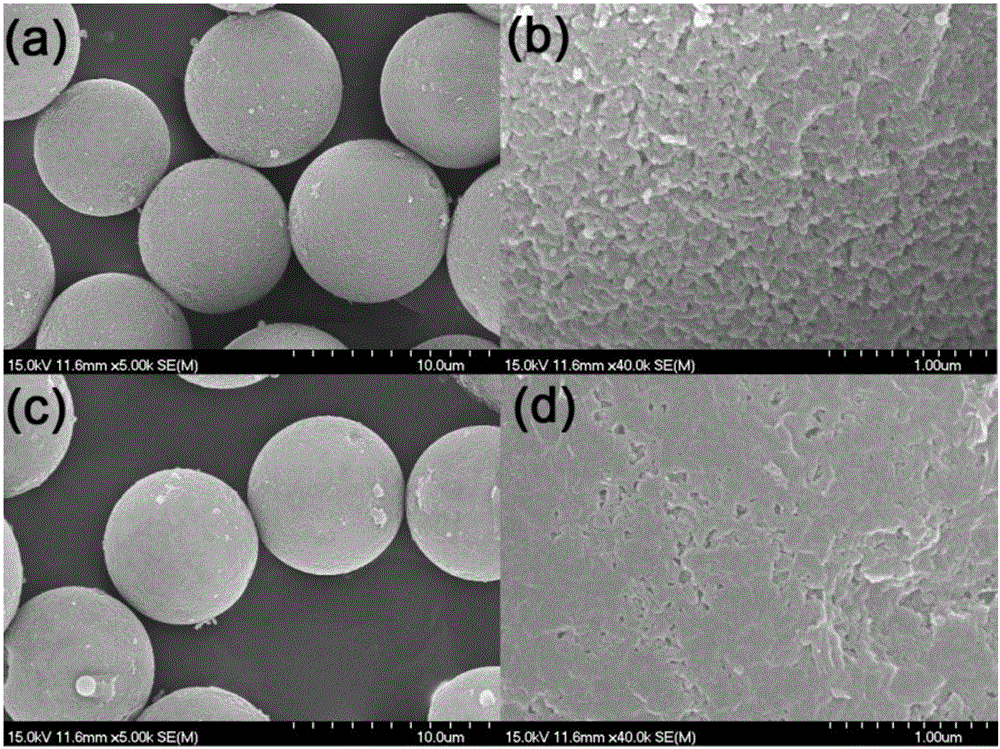

[0028] The preparation method of the polymer graphene composite chromatographic filler provided by the present invention is to reduce and agglomerate graphene oxide to polystyrene-divinylbenzene (PS-DVB) or On the surface of polyvinylbenzene-divinylbenzene (PEVB-DVB) microspheres, a wrinkled graphene shell is formed to obtain a polymer-graphene composite chromatographic filler, and the surface of a polymer-graphene composite chromatographic filler is prepared. The surface of graphene can undergo epoxy-amine, diazotization, and Diels-Alder reactions respectively, so that functional groups such as quaternary ammonium groups or carboxyl groups can be introduced into the surface of microspheres, and corresponding anion and cation exchange chromatography packings can be prepared. The chemically modified polymer carbon nanotube composite chromatographic filler is packed by homogenate method. The specific implementation steps of the above process are:

[0029] a. Synthesis of polyme...

Embodiment 1

[0043] Embodiment 1: This embodiment shows the process that in-situ reduction method prepares polymer graphene composite chromatographic filler. First, fully disperse 2.5g polystyrene-divinylbenzene (55% degree of cross-linking) resin in 80mL aqueous solution containing 6% (m / v) Triton X-100, then mix this solution with another 100mL 1mg / L of graphene oxide solution (containing 2 mL of ammonia water) was mixed, the solution was stirred at room temperature for 2 h, the temperature was raised to 95 degrees, and 20 mL of solution containing 90 mg of hydrazine hydrate was slowly added dropwise. After the above reaction was carried out at 95 degrees for 3 hours, the resin was filtered and washed with deionized water and ethanol to obtain a composite chromatographic filler with a graphene layer agglomerated on the surface.

Embodiment 2

[0044] Embodiment 2: This embodiment shows the process that distribution reduction method prepares polymer graphene composite chromatographic filler. First, heat 100mL of 1mg / L graphene oxide solution (containing 2mL of ammonia water) to 95°C, and slowly add dropwise to 20mL solution containing 90mg of hydrazine hydrate. After the above reaction was carried out at 95 degrees for 3 h, the above solution was filtered. The filtrate is collected and heated to 70 degrees, and 80 mL of 6% (m / v) triton X-100 aqueous solution dispersed with 2.5 g of polystyrene-divinylbenzene (55% degree of cross-linking) resin is slowly added dropwise , and stirred for 3h. Then the resin was filtered and washed with deionized water and ethanol to obtain a composite chromatographic filler with a graphene layer agglomerated on the surface with properties similar to that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com