Method for preparing slow-release and synergistic fucoidan nitrogen fertilizer by compound microbial fermentation

A technology of effective fucoidonium and compound microorganisms, which is applied in the field of compound microbial fermentation to prepare slow-release and high-efficiency fucoidonium nitrogen fertilizers, which can solve the problems of easy decomposition of additives, unstable long-term performance, and high production costs, and improve environmental adaptation ability, ensure the survival rate of bacteria, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Preparation of product A: Wash and remove fresh kelp and sargassum (mass ratio: 1:1), soak for 20 hours, grind, transfer to a fermenter, sterilize at 110°C for 30 minutes, and cool to 20°C get product A;

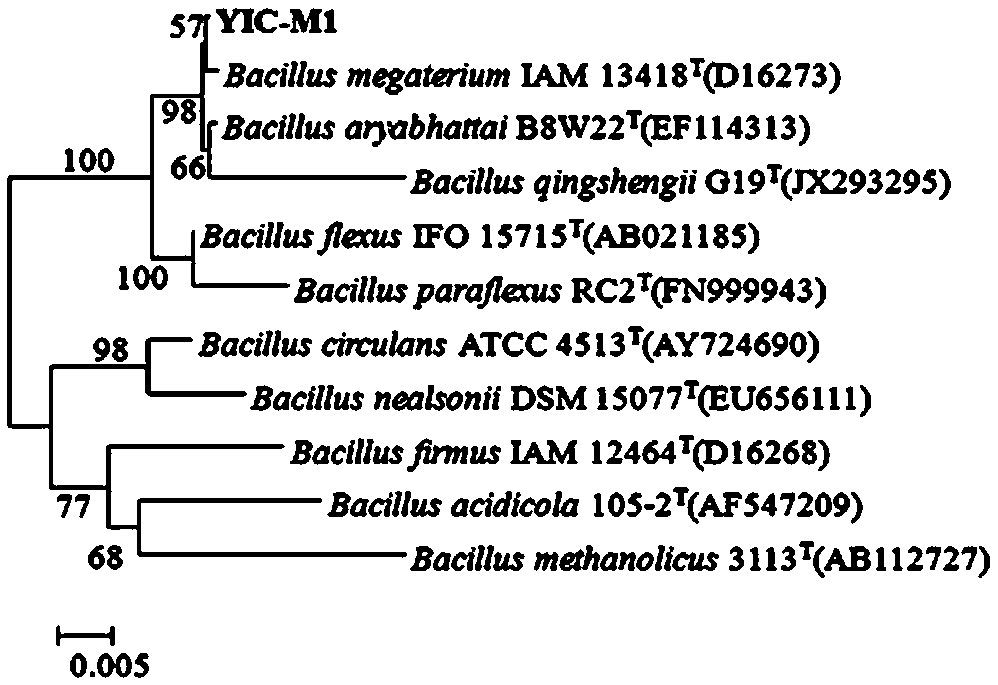

[0042] 2) Prepare seed solution: activate and expand Bacillus cereus to prepare Bacillus cereus seed solution X; activate and expand Bacillus megaterium to prepare Bacillus megaterium seed solution Y; activate and expand Bacillus amyloliquefaciens Cultivate to prepare Bacillus amyloliquefaciens seed solution Z;

[0043] The medium formula of described bacillus cereus activation and expansion culture is: soybean meal powder 20g, yeast extract 6g, sodium alginate 1.2g, bovine bile salt 0.05g, potassium dihydrogen phosphate 0.04g, sodium chloride 0.2g, Magnesium sulfate 0.2g, mannitol 9.5g, water 1000mL, adjust pH 6.8-7.0, expansion culture conditions: 33°C for 20h.

[0044] The medium formula for the activation and expansion of Bacillus megaterium is: sweet potato ...

Embodiment 2

[0054] 1) Preparation of product A: Wash fresh copper algae, remove impurities, soak for 24 hours, refine, transfer to a fermenter, sterilize at 120°C for 15 minutes, and cool to 20°C to obtain product A;

[0055] 2) Preparation of seed liquid: the operation method is the same as in Example 1.

[0056] 3) Preparation of product B: inoculate seed solution X into product A, the amount of seed solution X is 12% of the mass of product A, the fermentation temperature is 32°C, the pH value of the reaction is adjusted to 6.6 with citric acid and ammonia water, and the dissolved oxygen is controlled At 25%, the rotating speed is 180r / min, the ventilation rate is 850L / min, the pressure of the fermenter should be maintained at 0.03Mpa, and the fermentation time is 21h, to obtain product B;

[0057] 4) Preparation of product C: adjust the pH of product B to 4.5, cool the temperature in the fermenter to 4°C, store for 1 day, and then return the temperature to 25°C to obtain product C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com