Anti-flaming ceramic modified size and lithium ion battery membrane coated with same

A technology of lithium ion battery and modified slurry, applied in battery pack components, circuits, coatings, etc., can solve the problems of piercing the film, easy shrinkage, stress concentration, etc., to improve the uniformity of dispersion and reduce heat. The effect of spreading and improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the flame-retardant ceramic modified powder of the present invention specifically comprises the following steps:

[0052] A: Dilute the silane coupling agent with ethanol and water, wherein the volume ratio of silane coupling agent, ethanol and water is 20-22:70-72:8;

[0053] B: Put the inorganic particles and flame retardant into the stirrer heated to 50-60°C, slowly inject the diluted silane coupling agent into the stirrer with a dropper, stir evenly, and obtain the mixture;

[0054] C: drying the above mixture in a vacuum oven at 50-60° C. for 1-1.5 hours to obtain a flame-retardant ceramic modified powder.

[0055] The lithium-ion battery diaphragm provided by the invention is obtained by coating the flame-retardant ceramic modified slurry prepared by the method of the invention on the surface of a polyolefin microporous membrane to form a coating, and drying to obtain the lithium-ion battery diaphragm. Wherein, the surface modification t...

Embodiment 1

[0058] 1. Preparation of flame-retardant ceramic modified powder: First, take 1.5g of vinyltrimethoxysilane coupling agent, put it into a mixed solution of ethanol and water, stir evenly, and set aside. Wherein the volume ratio of coupling agent: ethanol: water is 20:72:8. Then put 35g of alumina and 15g of melamine polyphosphate into the agitator preheated to 60°C, slowly inject the diluted silane coupling agent into the agitator with a dropper, and stir thoroughly. Finally, it was dried in a vacuum oven at 60° C. for 1 hour to obtain a flame-retardant ceramic modified powder.

[0059] 2. Preparation of flame-retardant ceramic modified slurry: Add flame-retardant ceramic modified powder into a container containing 42.5 g of deionized water, stir at high speed for 30 minutes, and use a ball mill for ball milling. Then add 1 g of sodium hydroxymethyl cellulose and 5 g of polyacrylic acid in sequence, and stir at a high speed to form a flame-retardant ceramic modified slurry. ...

Embodiment 2

[0063] 1. Preparation of flame-retardant ceramic modified powder: First, take 1.5g of vinyltrimethoxysilane, put it into a mixed solution of ethanol and water, stir evenly, and set aside. Wherein the volume ratio of coupling agent: ethanol: water is 20:72:8. Then put 30g of alumina and 20g of ammonium polyphosphate into a stirrer preheated to 60°C, slowly inject the diluted silane coupling agent into the stirrer with a dropper, and stir thoroughly. Finally, it was dried in a vacuum oven at 60° C. for 1 hour to obtain a flame-retardant ceramic modified powder.

[0064] 2. Preparation of flame-retardant ceramic modified slurry: Add flame-retardant ceramic modified powder into a container containing 42.5 g of N-methylpyrrolidone, stir at high speed for 30 minutes, and perform ball milling with a ball mill. Then add 1 g of sodium hydroxymethyl cellulose and 5 g of polyvinylidene fluoride in sequence, and stir at a high speed to form a flame-retardant ceramic modified slurry.

[...

PUM

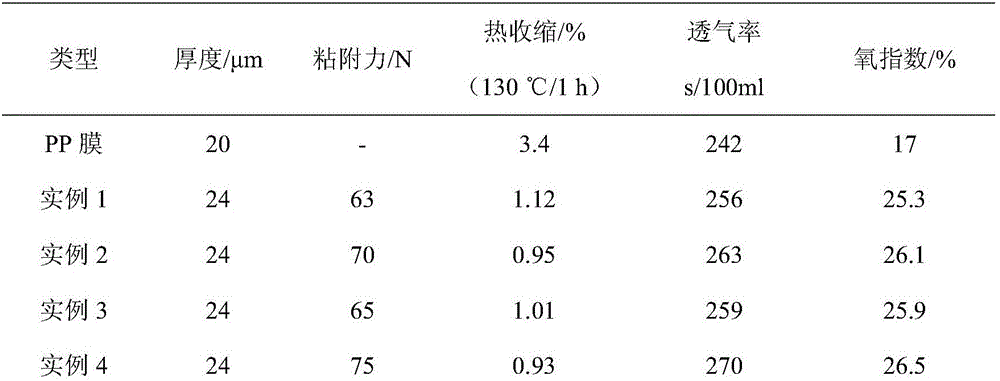

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com