Medium for co-cultivation of yeast and lactic acid bacteria and preparation method thereof

A culture medium and lactic acid bacteria technology, applied in the field of microorganisms, can solve problems such as complex production operations, and achieve long storage time, simple ingredients, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

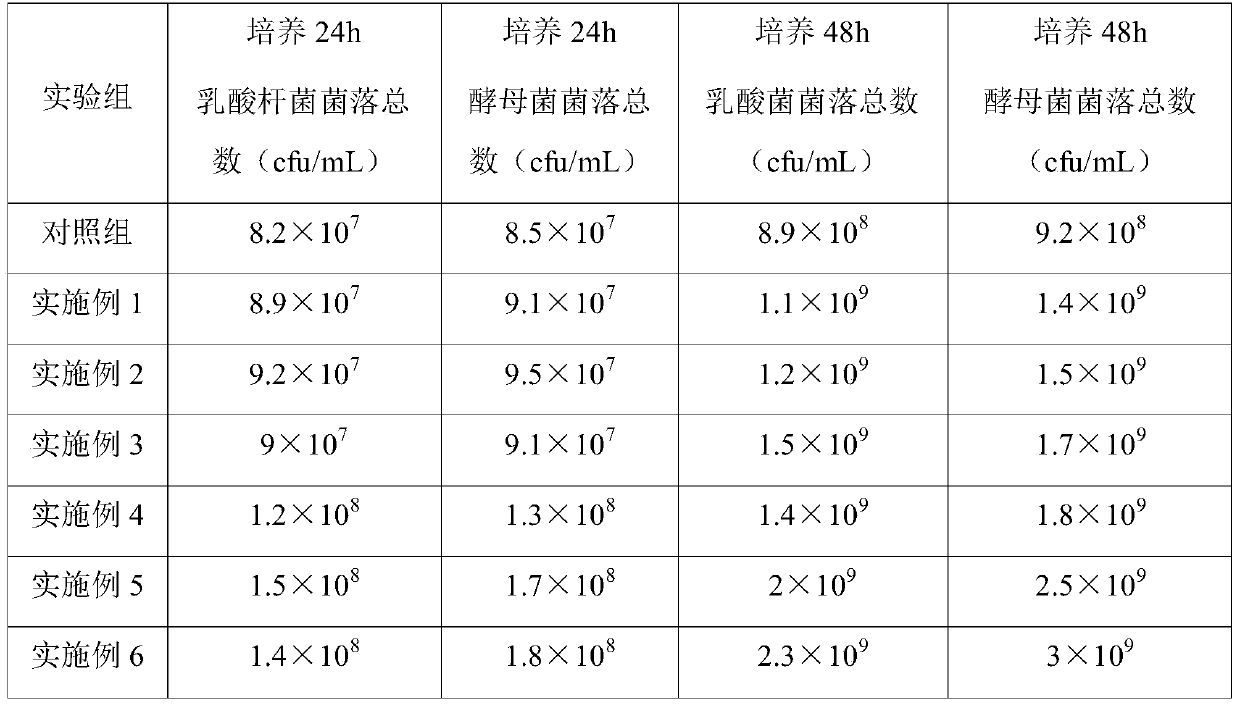

Examples

Embodiment 1

[0032] A culture medium for co-cultivation of yeast and lactic acid bacteria, comprising the following components in parts by weight:

[0033] 5 parts of brown rice, 6 parts of brown sugar and 122 parts of purified water.

[0034] The medium provided by this program contains brown rice and brown sugar, and brown rice is rich in starch, protein, fat, vitamins and 11 kinds of minerals. Brown sugar contains glucose, fructose and other monosaccharide and polysaccharide energy substances, folic acid, trace substances, amino acids, cellulose and other substances, and organic acids such as cellulose and polysaccharides, which provide rich carbon sources for yeast and lactic acid bacteria. Nitrogen source and other growth factors meet the growth and reproduction needs of yeast and lactic acid bacteria.

[0035] A preparation method for a medium for co-cultivation of yeast and lactic acid bacteria, comprising the following steps:

[0036] Step 1, wash 5 parts by weight of brown rice,...

Embodiment 2

[0040] On the basis of embodiment 1, after said step three, also include:

[0041] Step 4, add wood vinegar to the medium prepared in step 3 to contain 0.15mL wood vinegar per kilogram of medium, mix well, then add buffer solution to adjust the pH value of the medium to 5 in the medium . Provide a suitable acidity environment for the growth of yeast and lactic acid bacteria, and add wood vinegar to the medium to promote the growth of mycelium and fruiting bodies.

[0042] In the preparation method of the medium for the co-cultivation of yeast and lactic acid bacteria, the buffer solution is a HAc-NaAc buffer solution with a pH value of 7.

Embodiment 3

[0044]On the basis of Example 1, after the brown rice is washed in the step 1, before cooking, it also includes:

[0045] After the grapes are crushed, mixed with brown rice and soybean powder in a mass ratio of 0.5:1:0.5, immersed in 15 parts by weight of water, then 0.4 parts by weight of cellulase, 0.5 parts by weight of pectinase, 0.12 parts by weight of pectinase are added to the water. Amylase in parts by weight and protease in 0.5 parts by weight, and the pH value is adjusted to 6, enzymolysis is carried out at a temperature of 50° C. for 2.5 hours, and then cooked for 25 minutes to obtain brown rice. High-temperature cooking can deactivate the enzyme, so that the enzyme does not Hydrolyzes the cell wall of yeast. Enzymolysis of grapes, brown rice and soybean flour, which can destroy the cell walls of brown rice and grapes, is conducive to the hydrolysis of cellulose, pectin, starch and protein into glucose and amino acids, which can be directly used by yeast and lactic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com