Preparation method of carbon electrode material of porous structure sodium-ion battery

A sodium-ion battery, porous structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of difficult to guarantee the quality of electrode materials, difficult to meet, low capacity, etc. The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

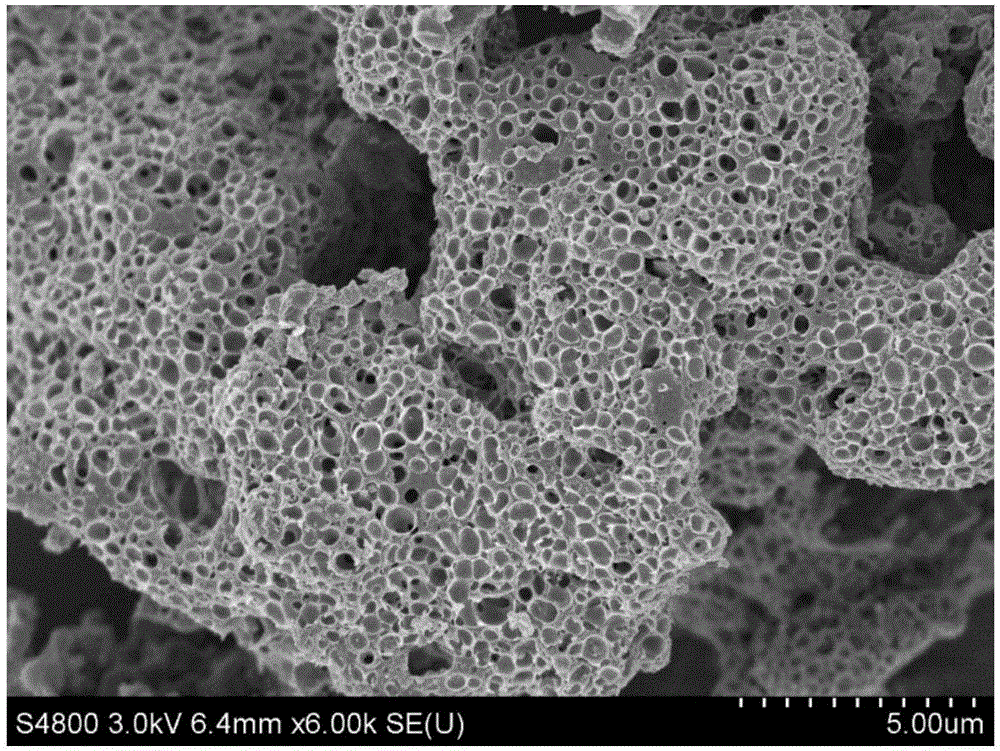

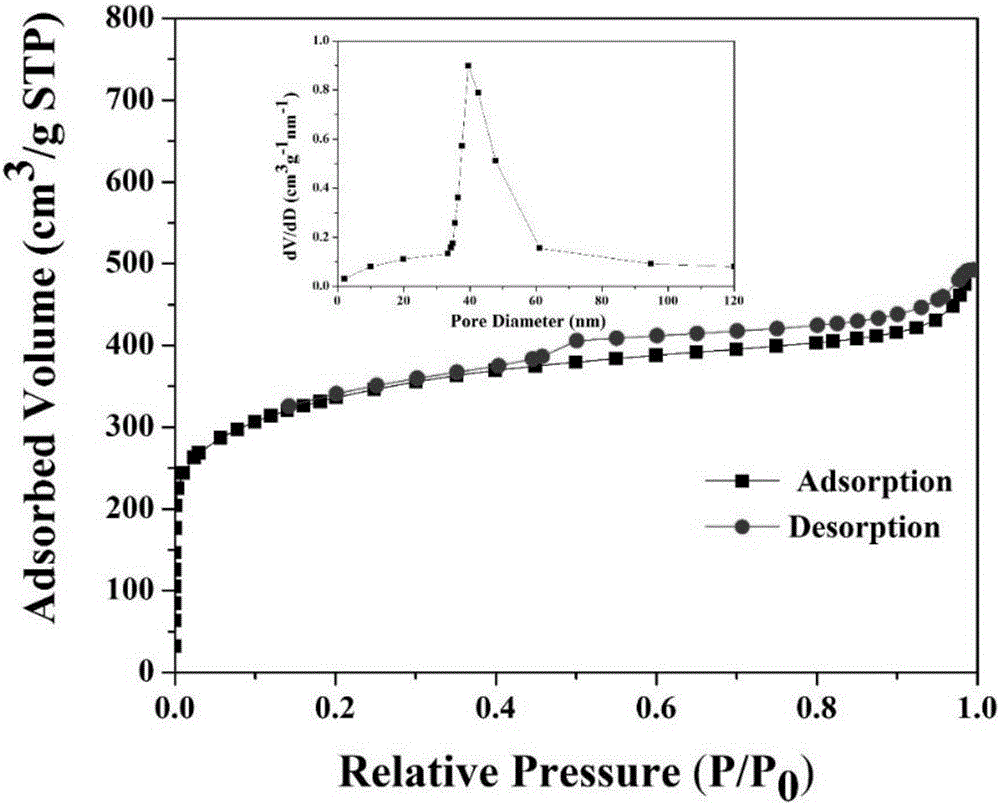

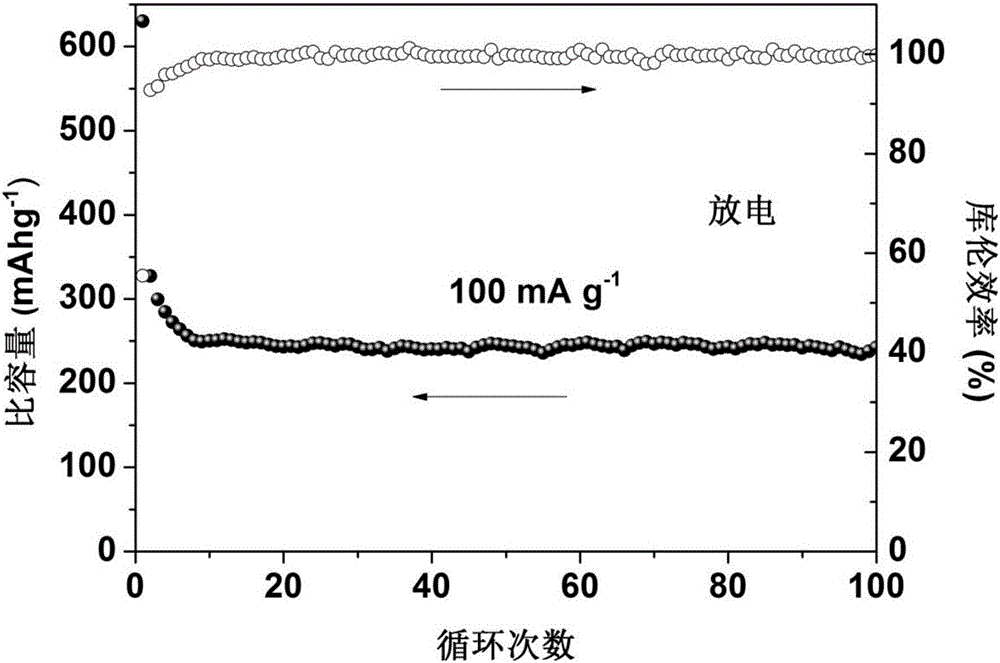

[0026] A preparation method of a porous structure sodium ion battery carbon electrode material, comprising the following steps:

[0027] 1) washing the leaves of thistle with deionized water, freeze-drying and pulverizing to obtain pulverized dry leaves of thistle;

[0028] 2) The activator KOH, NaOH, ZnCl 2 、K 2 CO 3 or Na 2 CO 3 Put it into distilled water according to the mass ratio of (0.5-5): 1 with the crushed dry leaves of thistle, wherein, add 1-5g of dry leaves of thistle to every 50mL of distilled water, stir magnetically for 2h to form a suspension, and then put it in 120- Hydrothermal reaction at 220°C for 2-24h, after the reaction is complete, magnetically stir the obtained mixture at 60-80°C for 4-6h to obtain a slurry-like product;

[0029] 3) raising the temperature of the slurry product to 500-1100°C at a heating rate of 1-10°C / min under the protective gas nitrogen or argon and keeping it warm for 1-6h to obtain a calcined product, wherein the flow rate o...

Embodiment 1

[0033] 1) washing the leaves of thistle with deionized water, freeze-drying and pulverizing to obtain pulverized dry leaves of thistle;

[0034] 2) the activator K 2 CO 3 Put the dried leaves of thistle into distilled water according to the mass ratio of 1:1, wherein, add 1g of dried leaves of thistle to every 50mL of distilled water, stir magnetically for 2h to form a suspension, and then transfer it to a hydrothermal kettle (filling ratio 50%) hydrothermal reaction at 180°C for 12h, after the reaction was completed, the obtained mixture was magnetically stirred at 80°C for 5h to obtain a slurry-like product;

[0035] 3) Transfer the slurry-like product to an atmosphere furnace, and raise the temperature to 700° C. at a heating rate of 10° C. / min under the protection of an argon atmosphere with an air flow of 50 sccm and keep it warm for 2 hours to obtain a calcined product;

[0036] 4) Soak the calcined product in a hydrochloric acid solution with a concentration of 2 mol / ...

Embodiment 2

[0039] 1) washing the leaves of thistle with deionized water, freeze-drying and pulverizing to obtain pulverized dry leaves of thistle;

[0040]2) Put the activator NaOH and the crushed dry leaves of thistle into distilled water according to the mass ratio of 5:1, wherein, add 5g of dry leaves of thistle to every 50mL of distilled water, stir magnetically for 2h to form a suspension, and then transfer to water In a hot kettle (filling ratio is 50%), hydrothermal reaction is carried out at 120°C for 2 hours. After the reaction is completed, the obtained mixture is magnetically stirred at 60°C for 4 hours to obtain a slurry-like product;

[0041] 3) Transfer the slurry-like product to an atmosphere furnace, and raise the temperature to 1100° C. at a heating rate of 5° C. / min under the protection of a nitrogen atmosphere with an airflow of 20 sccm and keep it warm for 4 hours to obtain a calcined product;

[0042] 4) Soak the calcined product in a hydrochloric acid solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com