SBS aqueous binder and preparation method thereof

A water-based adhesive, active technology, applied in the direction of adhesive types, rosin adhesives, polymer adhesive additives, etc., can solve the problems of poor affinity and poor compatibility, and achieve enhanced affinity and adhesion Good effect of improvement, solubility and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In a 5L polymerization kettle, add 3L cyclohexane, 100mL styrene and a small amount of tetrahydrofuran, add the calculated catalyst butyllithium after the temperature rises to 60°C, and initiate polymerization. After one stage of polymerization is completed, add 400mL butadiene and 100mL benzene Ethylene was polymerized in the second and third stages. After the second and third stages of polymerization were completed, active SBS was obtained. The system temperature was maintained at 80°C, and 10 mL of 2-vinylpyridine was added to carry out the fourth stage of polymerization. The polymerization time was controlled at 5 minutes. After the polymerization, the reaction product is stripped to remove cyclohexane, and then the product is dried to obtain polar SBS. The number average molecular weight of the product is 108956, and the molecular weight distribution index is 1.15. The conversion rate of 2-vinylpyridine is 99.7%.

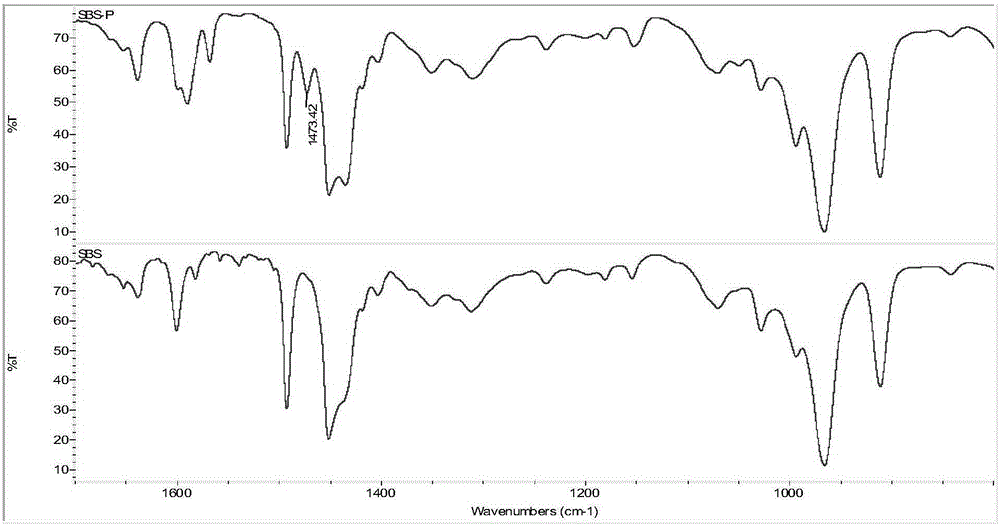

[0024] The infrared spectrogram of gained polarity...

Embodiment 2

[0033] Add polar SBS, tackifying resin, and organic solvent into the container, mix and dissolve, add emulsifier, deionized water, and emulsify with a high-shear emulsifier (ram≥10,000 rpm) to obtain a water-emulsified adhesive. The formula and properties of water-emulsified adhesive are as formula 1 and 2:

[0034] 1 # Recipe: Polar SBS 100g, Terpene 210g, C 9 90g, 6 # 320g of solvent oil, 80g of dichloromethane, 1000g of deionized water, 2mL of anionic emulsifier (such as sodium dodecylphenyl ether disulfonate), 8mL of nonionic emulsifier (such as alkylphenol polyoxyethylene ether), Appropriate amount of VAE emulsion, emulsion viscosity 100mPa·S.

[0035] Stability for 3 weeks without delamination.

[0036] 2 # Recipe: polar SBS 100g, terpene 150g, rosin 60g, C 9 90g, 6 # Solvent oil 320g, methylene chloride 80g, deionized water 1000g, cationic emulsifier (such as sodium rosinate) 2mL, nonionic emulsifier (such as octylphenol polyoxyethylene ether) 2mL, appropriate ...

Embodiment 3

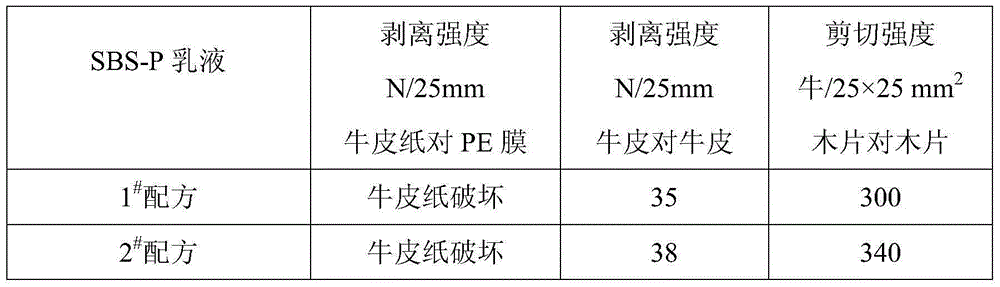

[0039] to 1 # ,2 # The polar SBS emulsion of the formula was tested for adhesive performance, and the results are as follows.

[0040] The viscosity is measured with a NDJ-1 rotational viscometer according to GB / T2794-1995.

[0041] Peel strength is measured according to GB / T2791-1995 standard.

[0042]Shear strength is measured according to GB / T 17517-1998.

[0043] Table 1 Adhesive properties of polar SBS aqueous emulsion

[0044]

[0045] The above water-based emulsion adhesives can meet the requirements for paper-plastic lamination and bonding of kraft paper and kraft paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com