Lithium battery current collector having protective function

A protection function, lithium battery technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve problems such as abnormal rise, thermal runaway, lithium battery protection, etc., to prevent thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] For the lithium battery current collector with protective function of the present invention, its specific implementation is as follows:

[0029] In conductive composites with a positive temperature effect on resistance,

[0030] The polymer substrates are: polyethylene, chlorinated polyethylene, oxidized polyethylene, polyvinyl chloride, butadiene-acrylonitrile copolymer, acrylonitrile-butadiene-styrene copolymer, polystyrene, polycarbonate , polyamide, polyimide, polyethylene terephthalate, polybutylene terephthalate, polyphenylene ether, polyphenylene sulfide, polyoxymethylene, phenolic resin, polytetrafluoroethylene, four Vinyl fluoride-hexafluoropropylene copolymer, polytrifluoroethylene, polyvinyl fluoride, maleic anhydride grafted polyethylene, polypropylene, polyvinylidene fluoride, epoxy resin, ethylene-vinyl acetate copolymer, polymethacrylate One of esters, ethylene-acrylic acid copolymers and mixtures thereof;

[0031] The resistivity of the conductive powd...

Embodiment 1

[0033] Mix polyethylene and conductive ceramic powder according to the ratio of PTC resistance, set the temperature of the internal mixer to 180 degrees, and the speed to 30 rpm. After 15 minutes of refining, the material is discharged, and a conductive composite material with a positive temperature effect of resistance is obtained.

[0034] The above-mentioned melt-mixed conductive composite material with the positive temperature effect of resistance is rolled by an open mill to obtain a conductive composite material sheet with a thickness of 0.1 mm, which is then hot-pressed into a sheet with a thickness of 0.02 mm. Conductive composite layer with positive temperature effect of resistance.

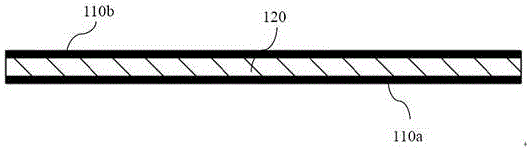

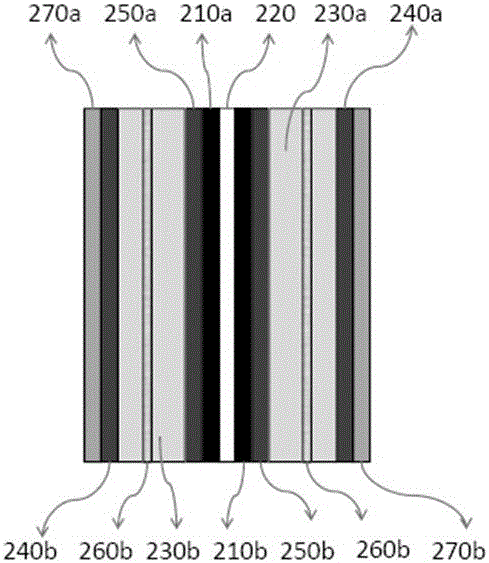

[0035] The two first and second conductive composite material layers 110a, 110b with the positive temperature effect of resistance are pressed according to figure 1 The metal copper foil 120 is placed on both sides as shown. The above-mentioned three layers are stacked and tightly comb...

Embodiment 2

[0037] The ratio and processing technology of the conductive composite material with the positive temperature effect of resistance are the same as those in Example 1, except that the metal copper foil is changed to metal aluminum foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size distribution range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com