Lactating sow feed and preparation method thereof

A technology for sucking sows and feed, which is applied in the field of sucking sows' feed and its preparation, which can solve the problems of limited dosage and poor palatability, and achieve the effects of increasing feed intake, preventing sows from constipation, and improving palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

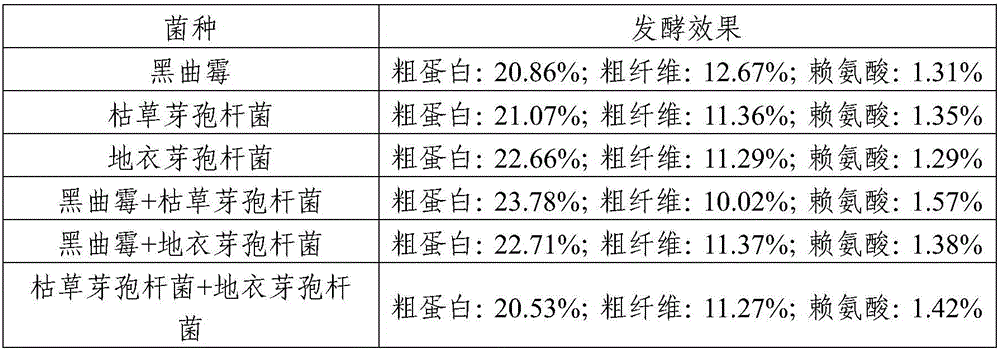

[0034] The preparation of embodiment 1 fermented leaf powder

[0035] (1) Preparation of mixed bacterial liquid of Aspergillus niger and Bacillus subtilis:

[0036] Preparation of Aspergillus niger spore suspension:

[0037] Seed medium (PDA) preparation: distilled water 1000mL, potato extract powder 6g, glucose 20g, agar 16g, sterilized at 115°C for 30min;

[0038] Strain preparation: insert the activated mold into the PDA medium with an inoculation loop, and culture at a constant temperature of 30°C for 3-4 days until the spores mature;

[0039] Preparation of the spore suspension: elute the spores with an appropriate amount of sterile water, put them into a shaker flask equipped with glass beads, shake horizontally at 140r / min for 1h, and make a concentration of 1×10 after hemocytometer counting. 6~7 CFU / mL of spore suspension.

[0040] Preparation of Bacillus subtilis bacterial liquid: 3g / L beef extract, 10g / L peptone and 5g / L sodium chloride were dissolved in an approp...

Embodiment 2

[0047] The preparation of embodiment 2 fermented leaf powder

[0048] (1) Preparation of Aspergillus niger and Bacillus subtilis mixed bacterial liquid: with embodiment 1

[0049] (2) Mixed fermentation:

[0050] After mixing the dried and pulverized leaves and 10% glucose water according to the mass concentration (W:W=2:1), add 12% mixed bacterial liquid of Aspergillus niger and Bacillus subtilis respectively, after stirring evenly, in 32°C Under the condition of constant temperature, the Qupan was solid-state fermentation for 6 days.

[0051] (3) Dry crush detection:

[0052] Dry and pulverize after fermentation, and pass through a 40-mesh sieve.

[0053] Before fermentation, the leaf powder was detected: the content of crude protein was 20.13%, the content of crude fiber was 14.32%, and the content of lysine was 1.26%. Fermented leaf powder: crude protein content 24.75%, crude fiber content 9.71%, lysine 2.02%.

Embodiment 3

[0054] The preparation of embodiment 3 fermented leaf powder

[0055] (1) Preparation of Aspergillus niger and Bacillus subtilis mixed bacterial liquid: with embodiment 1

[0056] (2) Mixed fermentation:

[0057] After mixing the dried and pulverized leaves with 10% mass concentration of glucose water (W:W=2:1), add 15% mixed bacterial liquid of Aspergillus niger and Bacillus subtilis respectively, stir evenly, and set the temperature at 35°C Under the condition of constant temperature, the koji plate was fermented in solid state for 5 days.

[0058] (3) Dry crush detection:

[0059] Dry and pulverize after fermentation, and pass through a 40-mesh sieve.

[0060] Before fermentation, the leaf powder was detected: the content of crude protein was 20.13%, the content of crude fiber was 14.32%, and the content of lysine was 1.26%. After testing, in the fermented leaf powder: the content of crude protein is 23.95%, the content of crude fiber is 9.86%, and the content of lysine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com