Cerium-based catalyst for benzene low-temperature catalytic removal, and preparation and application thereof

A cerium-based catalyst, low-temperature catalysis technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of ecological environment toxicity and high reaction temperature. , inapplicability and other problems, to achieve the effect of low cost, easy availability of raw materials and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

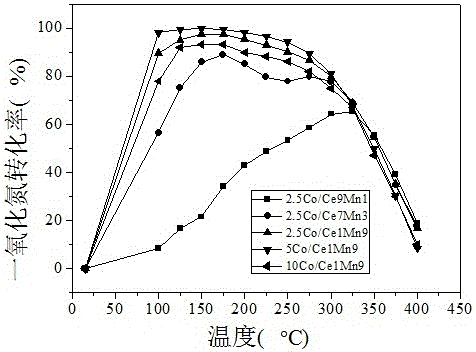

Embodiment 1

[0018] Weigh 1.79 grams of 50% manganese nitrate solution, 19.5 grams of cerium nitrate, dissolve in 200 milliliters of water, stir and dissolve at room temperature, add dropwise 30 milliliters of 2.9 mol / liter ammonium carbonate aqueous solution, continue to stir for 2 hours, filter and wash, 70 ℃ Dry in an oven for 12 hours, and then bake in a muffle furnace at 500° C. for 4 hours to obtain cerium manganese oxide Ce9Mn1.

[0019] Weigh 0.09 g of cobalt nitrate and dissolve it in 1.00 ml of deionized water to obtain the cobalt solution, add it dropwise to 1.0 g of Ce9Mn1 catalyst, impregnate it for 6 hours, put it in an oven at 70 ° C for 12 hours, and then put it in a muffle furnace for 500 Calcined at ℃ for 4 hours to obtain a 2.5%Co / Ce9Mn1 catalyst.

Embodiment 2

[0021] Compared with Example 1, the difference is that the quality of 50% manganese nitrate solution is 5.37 grams, the quality of cerium nitrate is 15.2 grams, and the concentration of ammonium carbonate aqueous solution is 2.7 mol / liter, and other operating conditions are identical with embodiment 1, obtain 2.5%Co / Ce7Mn3 catalyst.

Embodiment 3

[0023] Compared with Example 1, the difference is that the quality of 50% manganese nitrate solution is 16.1 grams, the quality of cerium nitrate is 2.17 grams, and the concentration of ammonium carbonate aqueous solution is 2.1 mol / liter, and other operating conditions are identical with embodiment 1, obtain 2.5%Co / Ce1Mn9 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com