A kind of pretreatment method of lignocellulose

A lignocellulose and pretreatment technology, applied in the field of bioengineering and chemical industry, can solve the problems of low conversion rate of cellulase hydrolysis, increase the amount of auxiliary materials, equipment failure, etc., to improve the recycling rate and enzymatic conversion of cellulose Rate, reduce equipment failure rate, reduce the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

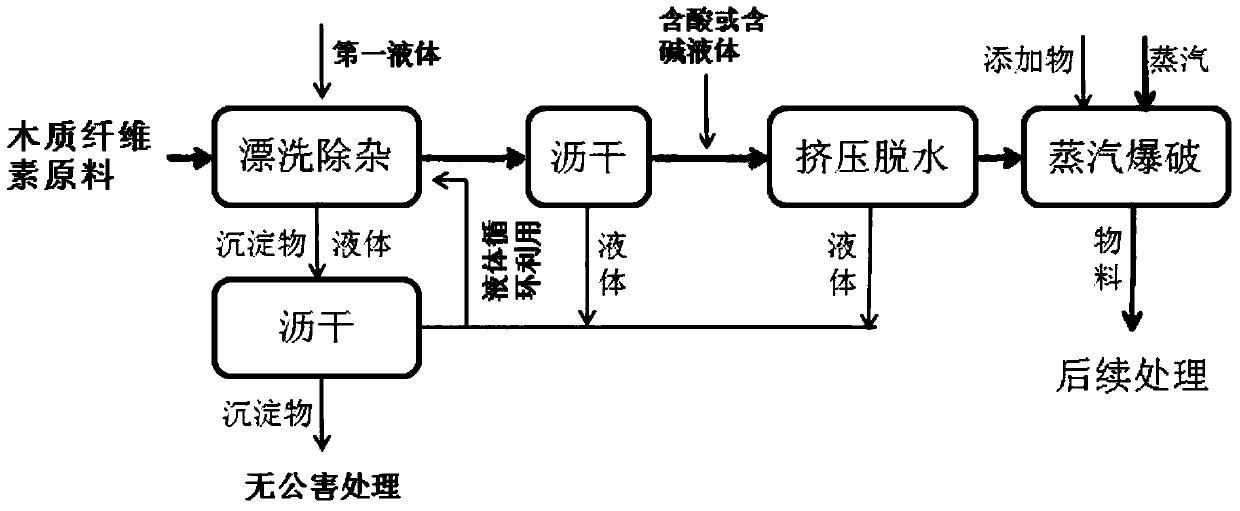

Method used

Image

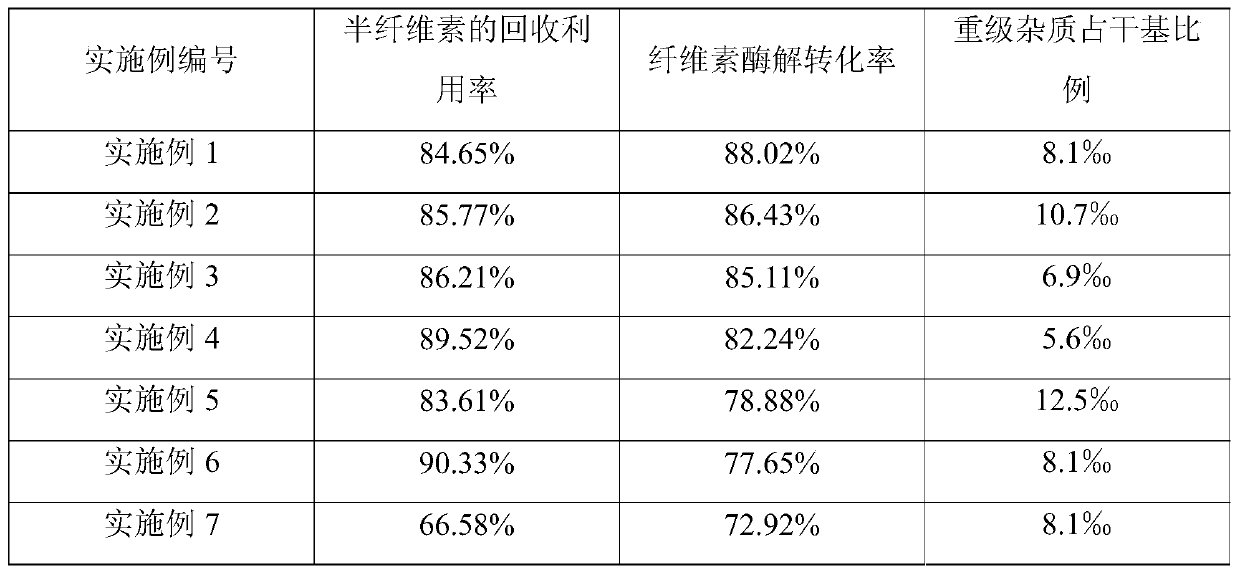

Examples

Embodiment 1

[0032] This example is used to illustrate the lignocellulose pretreatment method of the present invention.

[0033] Lignocellulose pretreatment methods include:

[0034] (1) 10kg of crushed lignocellulose raw material is mixed with 200kg of 1.6% by weight sulfuric acid solution for rinsing and impurity removal. The time for rinsing and wetting is 25min, and then the impurities deposited at the bottom of the rinsing and wetting device are discharged for rinsing and wetting. device, and perform draining treatment, landfill the sediment obtained from the draining treatment, recover the liquid obtained from the draining treatment and return it to the rinsing and impurity removal treatment for recycling.

[0035] (2) Extruding and dehydrating the impurity-removing material obtained by rinsing and removing impurities in step (1), so that the dry matter content of the material is 40%, obtaining 20kg of material, and returning the liquid obtained by the extruding and dehydrating proce...

Embodiment 2

[0039] This example is used to illustrate the lignocellulose pretreatment method of the present invention.

[0040] Lignocellulose pretreatment methods include:

[0041] (1) Mix 10kg of crushed lignocellulosic raw materials with 160kg of 0.97% by weight sodium hydroxide solution for rinsing and impurity removal treatment. The time for rinsing and wetting is 30min, and then the impurities deposited at the bottom of the rinsing and wetting device are discharged and rinsed Wet the device and perform draining treatment, return the sediment obtained from the draining treatment to the field, and recover the liquid obtained from the draining treatment and return it to the rinsing and impurity removal treatment for recycling.

[0042] (2) Extruding and dehydrating the impurity-removing material obtained by rinsing and removing impurities in step (1), so that the dry matter content of the material is 40%, obtaining 20kg of material, and returning the liquid obtained by the extruding an...

Embodiment 3

[0048] Lignocellulose pretreatment methods include:

[0049] (1) Mix 10 kg of pulverized lignocellulose raw materials with 250 kg of process primary water for rinsing and impurity removal treatment. The time for rinsing and wetting is 20 minutes, and then the impurities that have settled to the bottom of the rinsing and wetting device are discharged from the rinsing and wetting device, and Perform draining treatment, landfill the sediment obtained from the draining treatment, recover the liquid obtained from the draining treatment and return it to the rinsing and impurity removal treatment for recycling.

[0050] (2) Extruding and dehydrating the impurity-removing material obtained by rinsing and removing impurities in step (1), so that the dry matter content of the material is 50%, obtaining 16kg of material, and returning the liquid obtained by the extruding and dehydrating process to Recycled in rinsing and impurity removal treatment.

[0051] (3) Mix 16kg of material obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com