Piezoelectric ceramic filter membrane and device using same

A piezoelectric ceramic and ceramic membrane technology, applied in the field of functional ceramic membrane separation, can solve the problems of low general applicability, silver poisoning, and single anti-pollution performance of ceramic membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: The piezoelectric ceramic filter membrane is obtained by coating a mixture of aluminum-modified zinc oxide conductive material and polystyrene on the surface of a conventional commercially available ceramic membrane and sintering at 1200°C to obtain a piezoelectric filter membrane with a piezoelectric layer. Electroceramic filter membrane; when coating and preparing, the mixture of doped aluminum-modified zinc oxide conductive material and polystyrene is the ratio of doped aluminum-modified zinc oxide conductive material and polystyrene in a mass ratio of 5:1 Prepared by mixing, the coating thickness is 20 μm, and the aluminum-doped zinc oxide conductive material is prepared by referring to the method in Yue Renliang's "Liquid Phase Flame Combustion Synthesis and Conductivity Research of Aluminum Doped Nano Zinc Oxide".

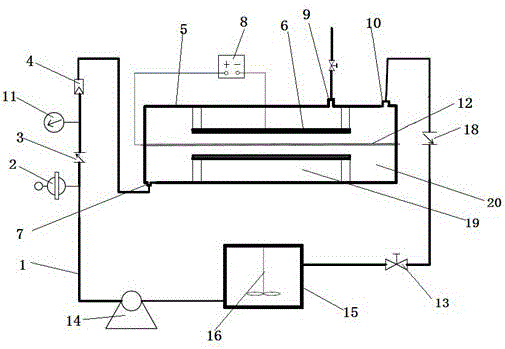

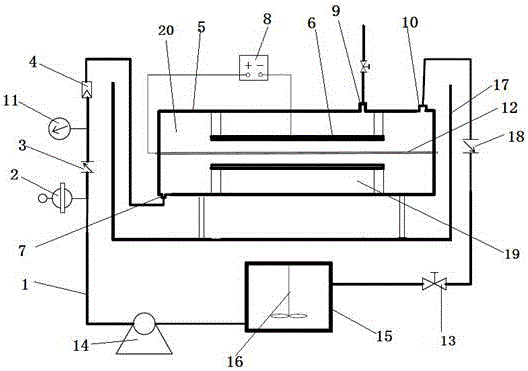

[0035] like figure 1 As shown, the device using the piezoelectric ceramic filter membrane includes a fluid delivery pipe 1, a pulsation dam...

Embodiment 2

[0040] Example 2: The piezoelectric ceramic filter membrane is a microfiltration piezoelectric ceramic with a piezoelectric layer obtained by coating a mixture of barium titanate and polyethylene glycol on the surface of a conventional commercially available microfiltration ceramic membrane and sintering at 1000 ° C. Filter membrane; during coating preparation, the mixture of barium titanate and polyethylene glycol is prepared by mixing barium titanate and polyethylene glycol at a mass ratio of 4:1, and the coating thickness is 50 μm.

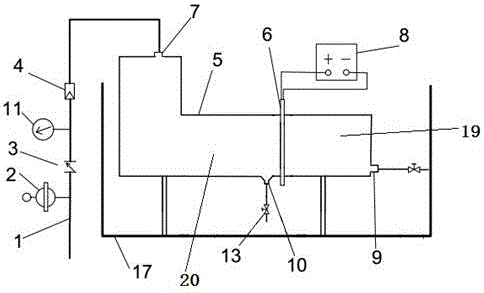

[0041] like image 3 As shown, the device using the piezoelectric ceramic filter membrane includes a fluid delivery pipe 1, a pulsation damper 2, a back pressure valve 3, a flow meter 4, a separation box 5, a piezoelectric ceramic filter membrane 6, a power supply 8, and an ultrasonic device 17; The fluid delivery pipe 1 communicates with the fluid inlet 7 on the separation box 5, and the piezoelectric ceramic filter membrane 6 is fixed in the ...

Embodiment 3

[0045] Example 3: Referring to the method of Example 2, a conventional commercially available microfiltration ceramic membrane is coated with a mixture of lead zirconate titanate and polyethylene oxide and sintered at 1150°C. During coating preparation, zirconate titanate The mixture of lead and polyethylene oxide is prepared by mixing lead zirconate titanate and polyethylene oxide at a mass ratio of 4.5:1, and the coating thickness is 80 μm to obtain a piezoelectric ceramic filter with a piezoelectric layer. membrane.

[0046] use as image 3 The shown device filters and separates dust-laden waste gas (the average particle size of dust is 8.9 μm, and the density is 10mg / m³). The operating conditions are consistent, and it runs continuously for 8 hours. The interception rate of dust is as high as 96%. Next, the permeation flux of the flat piezoelectric ceramic microfiltration membrane is from 2370L m -2 h -1 · bar -1 down to 2230 L·m -2 h -1 · bar -1 , without the coope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com