A method for preparing high-purity zinc sulfate heptahydrate from zinc-containing blast furnace gas mud

A technology of blast furnace gas mud and zinc sulfate heptahydrate, applied in the direction of zinc sulfate, etc., can solve the problems of low recovery rate of physical method treatment, high energy consumption for treatment, and large storage area, and achieves good economic benefits and low energy consumption. , The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

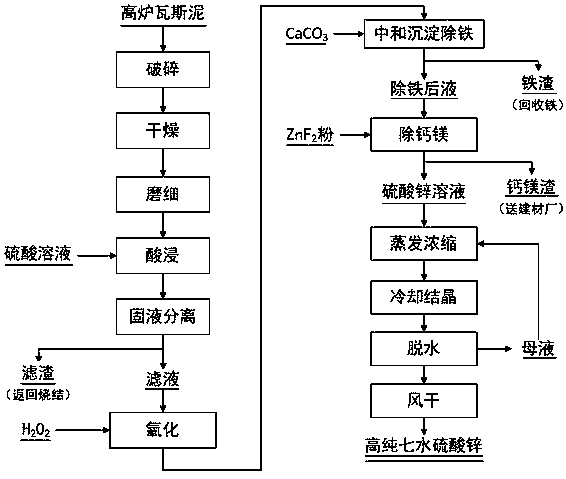

[0022] Such as figure 1 Shown, this zinc-containing blast furnace gas mud prepares the method for high-purity zinc sulfate heptahydrate, and it comprises the following concrete steps:

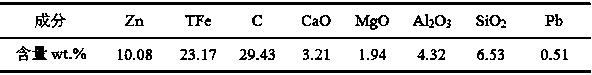

[0023] (1) Firstly crush, dry and grind the massive zinc-containing blast furnace gas mud (composition analysis is shown in Table 1) to obtain powdery zinc-containing blast furnace gas mud material with a particle size of 0.074mm~0.1mm, and then add it to the sulfuric acid solution Acid leaching in medium (at 60°C and a stirring speed of 200r / min, the powdery zinc-containing blast furnace gas mud material is added to a 1.22mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:3g / ml for 10 minutes, and after leaching Set aside to settle for 10 minutes, then solid-liquid separation to obtain filter residue and filtrate), leaching ore pulp for solid-liquid separation to obtain filter residue and filtrate, add hydrogen peroxide solution and limestone to oxidize and neutralize iron precipitat...

Embodiment 2

[0031] Such as figure 1 Shown, this zinc-containing blast furnace gas mud prepares the method for high-purity zinc sulfate heptahydrate, and it comprises the following concrete steps:

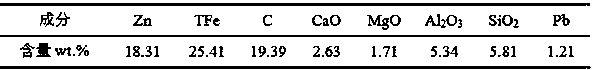

[0032] (1) Firstly crush, dry and grind the massive zinc-containing blast furnace gas mud (composition analysis shown in Table 2) to obtain powdery zinc-containing blast furnace gas mud material with a particle size of 0.074mm~0.1mm, and then add it to the sulfuric acid solution Acid leaching in medium (at 60°C and a stirring speed of 200r / min, the powdery zinc-containing blast furnace gas mud material is added to a 1.5mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:5g / ml for leaching for 20min, after leaching Set aside to settle for 15 minutes, then solid-liquid separation to obtain filter residue and filtrate), leaching ore pulp for solid-liquid separation to obtain filter residue and filtrate, adding hydrogen peroxide solution and limestone to oxidize and neutralize iron precipi...

Embodiment 3

[0040] Such as figure 1 Shown, this zinc-containing blast furnace gas mud prepares the method for high-purity zinc sulfate heptahydrate, and it comprises the following concrete steps:

[0041] (1) Firstly crush, dry and grind the massive zinc-containing blast furnace gas mud (composition analysis shown in Table 3) to obtain powdery zinc-containing blast furnace gas mud material with a particle size of 0.074mm~0.1mm, and then add it to the sulfuric acid solution acid leaching (at 60°C and a stirring speed of 200r / min, the powdery zinc-containing blast furnace gas mud material is added to a 1.38mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:4g / ml for leaching for 15min, after leaching Set aside to settle for 20 minutes, then solid-liquid separation to obtain filter residue and filtrate), leaching ore pulp for solid-liquid separation to obtain filter residue and filtrate, adding hydrogen peroxide solution and limestone to oxidize and neutralize iron precipitation in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com