Aqueous phase microwave preparation method of CdSeTdS quantum dot-polyacrylamide nanoparticles

The technology of polyacrylamide and nano-microspheres is applied in the field of synthesis of fluorescent nano-materials, which can solve the problems such as that the stability is not improved by an order of magnitude, and achieve the effects of easy control of process parameters, low synthesis cost and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

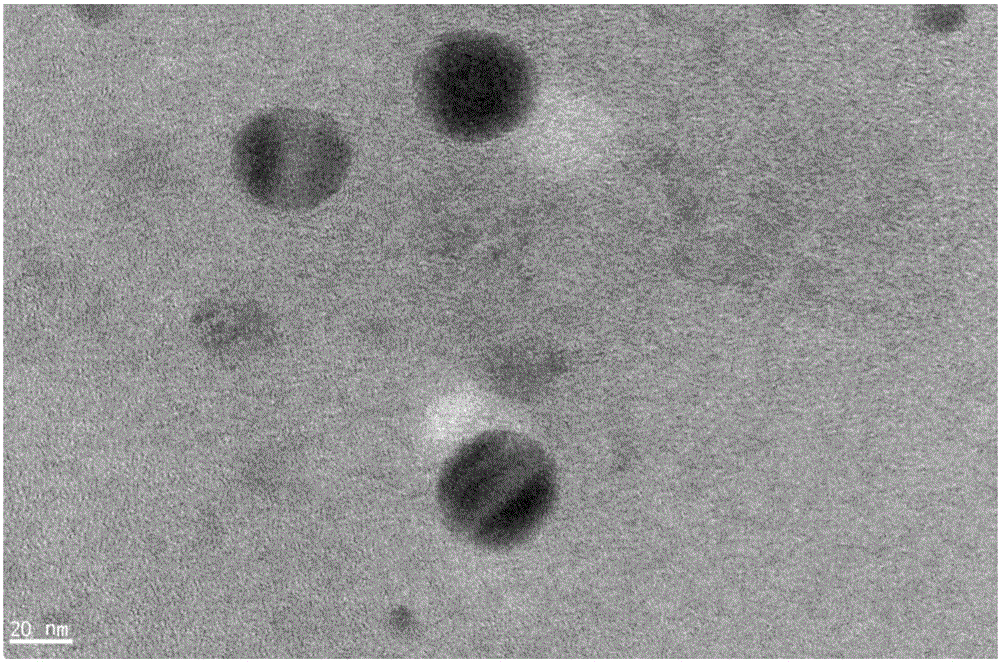

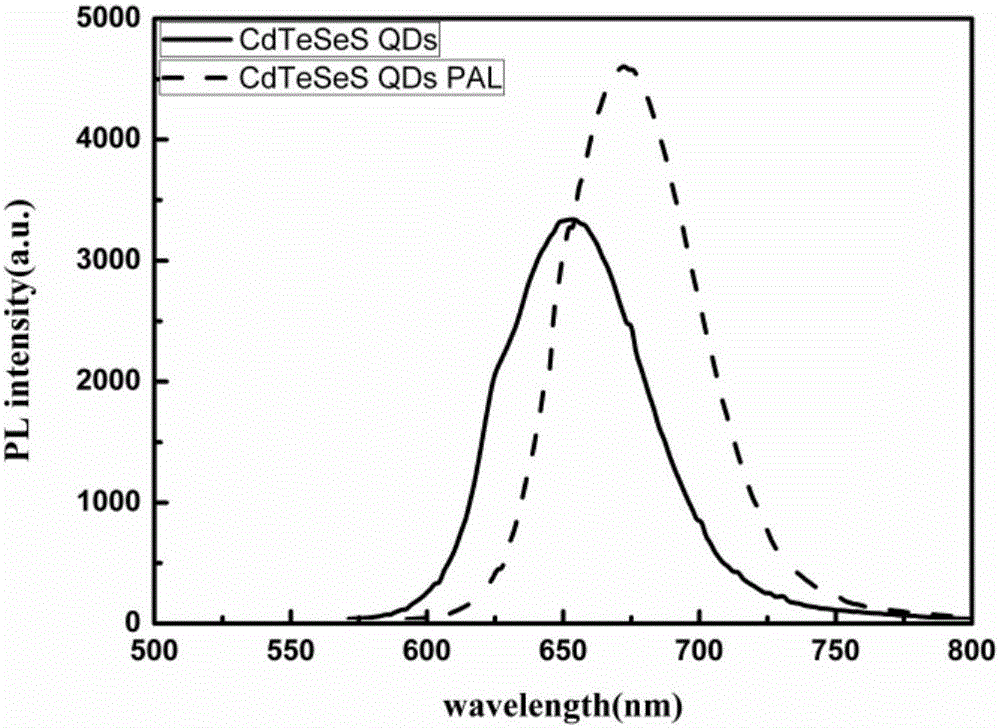

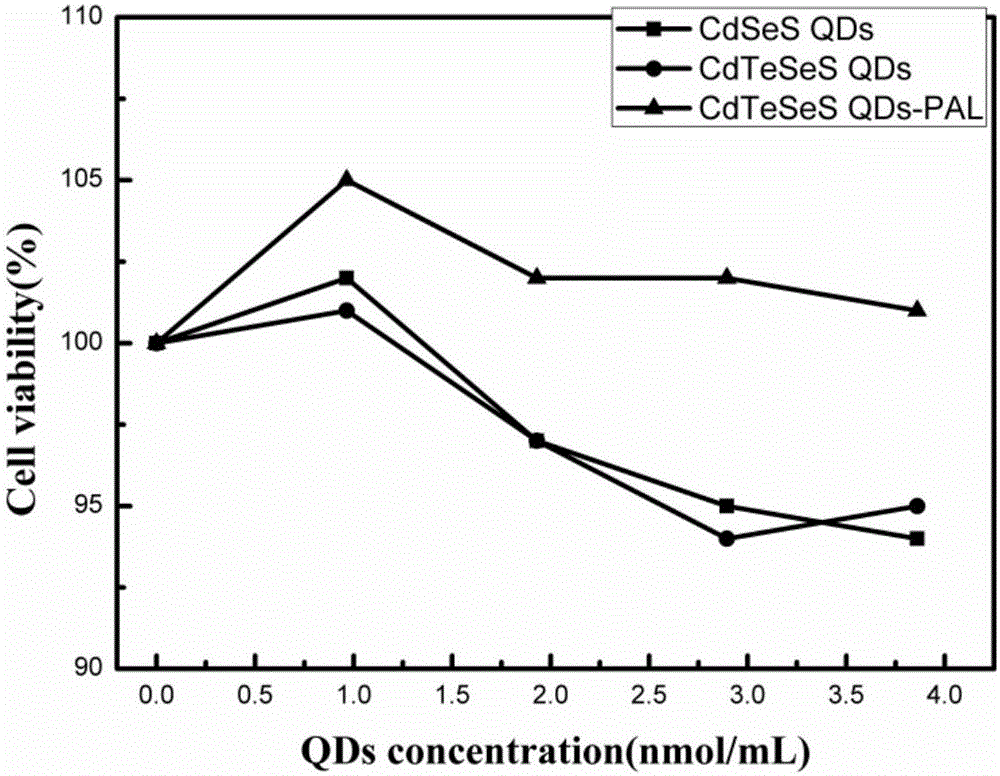

Image

Examples

Embodiment 1

[0031] Below by embodiment, further illustrate outstanding feature of the present invention, only in order to illustrate the present invention and in no way limit the present invention.

[0032] A CdTeSeS quantum dot-polyacrylamide nano-microsphere, which consists of: polyacrylamide (PAL, Mw=15,000, China Shanghai Chemical Reagent Company), selenium powder (Se, Tianjin Kemiou Chemical Reagent Development Center), Sodium tellurite (NaTeO 3 , produced by Aladdin Chemical Reagent Co., Ltd., the mass fraction is 97%), potassium borohydride (KBH 4 , Sinopharm Shanghai Chemical Reagent Co., Ltd., the mass fraction is 96%), cadmium chloride (CdCl 2 2.5H 2 O, Sinopharm Chemical Reagent Co., Ltd.), mercaptopropionic acid (MPA, Japan), and the rest were aqueous solutions.

[0033] In the described CdTeSeS alloy quantum dots, sodium tellurite+sodium selenosulfate, cadmium chloride (CdCl 2 2.5H 2 O), the molar ratio of mercaptopropionic acid (MPA), polyacrylamide is 1:8:20:0.00107, t...

Embodiment 2

[0046] A kind of CdTeSeS alloy quantum dot, it is composed of: polyacrylamide (PAL, Mw=15,000, China Shanghai Chemical Reagent Company), selenium powder (Se, Chemical Reagent Development Center, Kemiou, Tianjin), sodium tellurite (NaTeO 3 , produced by Aladdin Chemical Reagent Co., Ltd., the mass fraction is 97%), potassium borohydride (KBH 4 , Sinopharm Shanghai Chemical Reagent Co., Ltd., the mass fraction is 96%), cadmium chloride (CdCl 2 2.5H 2 O, Sinopharm Chemical Reagent Co., Ltd.), mercaptopropionic acid (MPA, Japan), and the rest were aqueous solutions.

[0047] In the described CdTeSeS alloy quantum dots, sodium tellurite+sodium selenosulfate, cadmium chloride (CdCl 2 2.5H 2 O), the molar ratio of mercaptopropionic acid (MPA), polyacrylamide is 1:8:20:0.00107, the molar ratio of sodium tellurite to sodium selenosulfate is 6:4, and heated at 130°C for 30min.

[0048] The pH of the solution is 8.6-9.2.

[0049] A water-phase microwave preparation method of CdSeTeS...

Embodiment 3

[0058] A water-phase microwave preparation method of CdSeTeS quantum dots-polyacrylamide nano-microspheres, the steps of which are:

[0059] 1. Weigh 2.3670g of selenium powder and 7.5624g of sodium sulfite in a 250mL three-neck flask, add 80mL of deionized water to it, and reflux in a water bath at 90°C for 8 or 9 or 10 hours until the solution is clear and transparent, and the black selenium powder disappears completely. The heat source stops heating. After naturally cooling to room temperature (20-25°C), transfer it to a 100mL volumetric flask and dilute it to the mark with deionized water, which is a 0.30mol / L sodium selenosulfate solution. The reaction equation is as follows:

[0060] Se+Na 2 SO 3 =Na 2 SeSO 3 ;

[0061] 2. Take 200 mL of anaerobic deionized water, add 2.5 mL of 0.10 mol / L cadmium chloride solution and 6 mL of 0.10 mol / L mercaptopropionic acid solution in turn, and adjust the pH value to 9 with 5 mol / L sodium hydroxide solution , add a certain amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com