A kind of bmp-2/ppla microsphere and preparation method thereof

A BMP-2, microsphere technology, applied in microcapsules, pharmaceutical formulations, peptide/protein components, etc., can solve the problems of unstable microspheres, different particle sizes of microspheres, short half-life, etc. Adhesion, diversified administration routes, simple and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

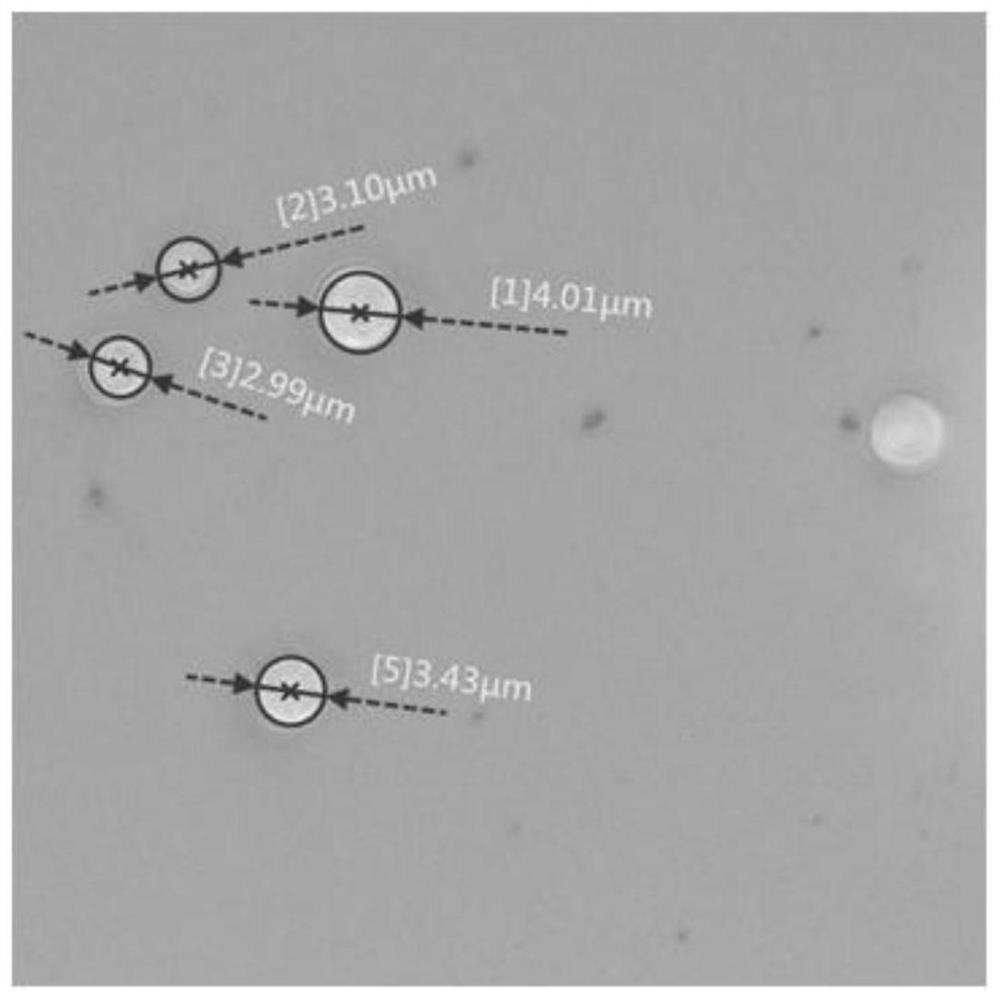

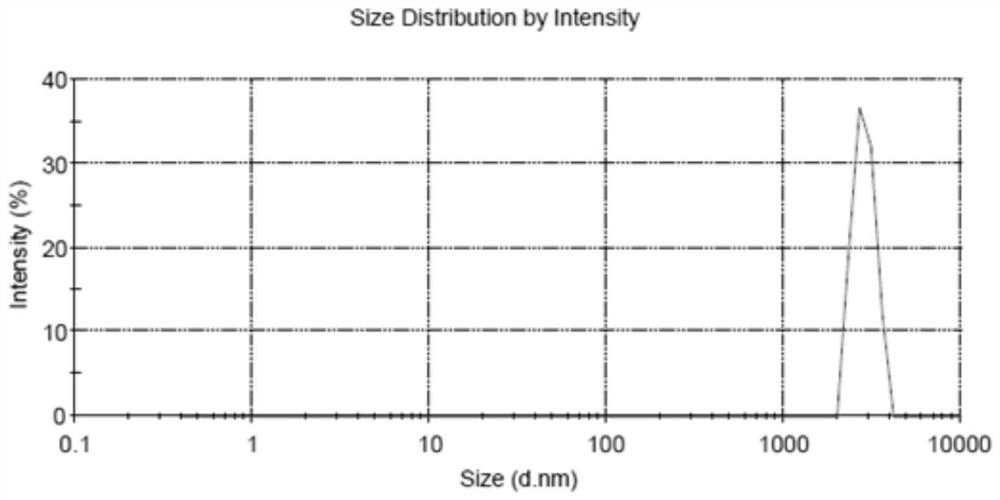

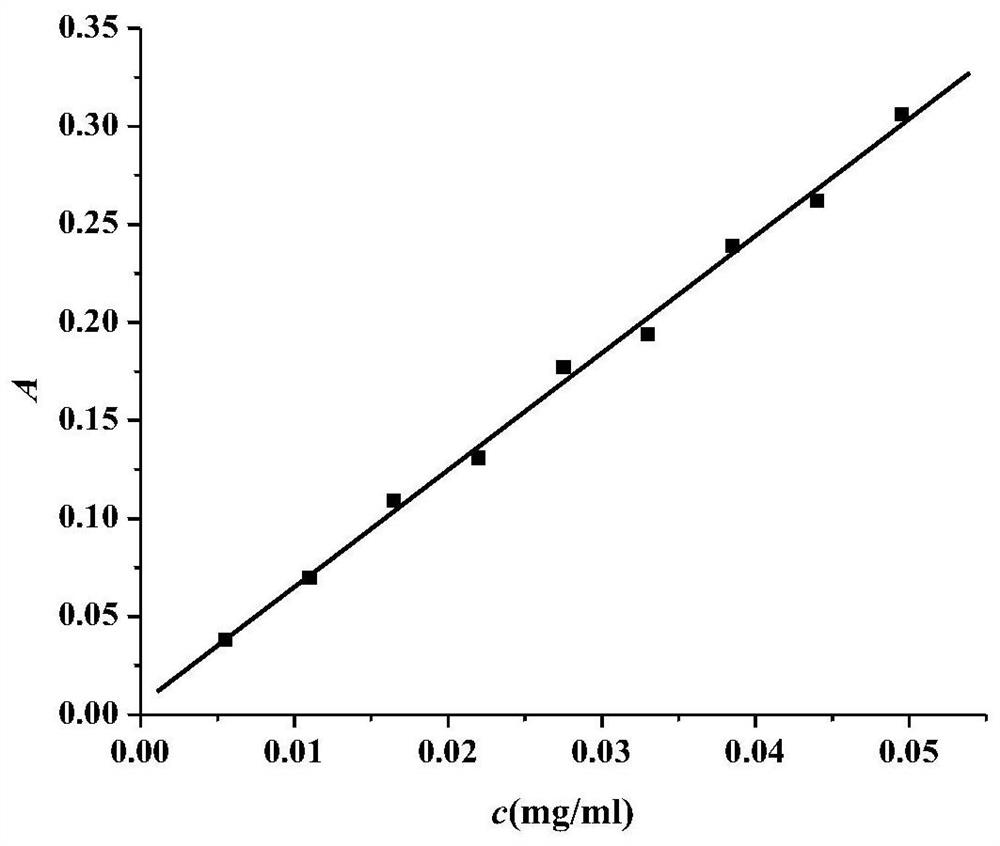

[0037] Embodiment 1: Preparation of BMP-2-PPLA-MS

[0038](1) Weigh a certain mass of PPLA and dissolve it in dichloromethane, shake and dissolve with a vortex machine, and prepare a solution with a PPLA concentration of 90 mg / ml. Take a certain volume of PPLA (molecular weight is 50000Da) solution and place it in the EP tube, add BMP-2 protein stock solution (concentration is 0.55mg / ml), control the volume ratio of BMP-2 protein stock solution and PPLA solution added to be 1: 5. Use a homogenizer to emulsify for the first time in an ice bath environment, with a shear speed of 15000 rpm and a time of 20 s, to obtain colostrum.

[0039] (2) Weigh a certain mass of PVA and dissolve it in a certain volume of distilled water, swell overnight and stir to dissolve or heat to 80 to 90°C to dissolve, configure it as a solution with a PVA mass fraction of 4%, cool to room temperature after the dissolution is complete, and Add a certain volume of PVA solution to the colostrum obtained ...

Embodiment 2

[0052] Embodiment 2: Preparation of BMP-2-PPLA-MS

[0053] (1) Weigh a certain mass of PPLA and dissolve it in dichloromethane, shake and dissolve with a vortex machine, and prepare a solution with a PPLA concentration of 95 mg / ml. Take a certain volume of PPLA (molecular weight is 50000Da) solution and place it in the EP tube, add BMP-2 protein stock solution (concentration is 0.55mg / ml), control the volume ratio of BMP-2 protein stock solution and PPLA solution added to be 1: 5. Use a homogenizer to emulsify for the first time in an ice bath environment with a shearing speed of 16,000 rpm and a time of 15 s to obtain colostrum.

[0054] (2) Weigh a certain mass of PVA and dissolve it in a certain volume of distilled water, swell overnight and stir to dissolve or heat to 80 to 90°C to dissolve, configure it as a solution with a PVA mass fraction of 4%, cool to room temperature after the dissolution is complete, and Add a certain volume of PVA solution to the colostrum obtain...

Embodiment 3

[0058] Embodiment 3: the preparation of BMP-2-PPLA-MS

[0059] (1) Weigh a certain amount of PPLA and dissolve it in dichloromethane, shake and dissolve with a vortex machine, and prepare a solution with a PPLA concentration of 85 mg / ml. Take a certain volume of PPLA (molecular weight is 50000Da) solution and place it in the EP tube, add BMP-2 protein stock solution (concentration is 0.55mg / ml), control the volume ratio of BMP-2 protein stock solution and PPLA solution added to be 1: 5. Use a homogenizer to emulsify for the first time in an ice bath environment with a shear speed of 14000 rpm and a time of 25 s to obtain colostrum.

[0060] (2) Weigh a certain mass of PVA and dissolve it in a certain volume of distilled water, swell overnight and stir to dissolve or heat to 80 to 90°C to dissolve, configure it as a solution with a PVA mass fraction of 4%, cool to room temperature after the dissolution is complete, and Add a certain volume of PVA solution to the colostrum obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com