Green high-performance concrete

A high-performance concrete and green technology, applied in the field of building materials, can solve the problems of high waste of resources, poor strength and durability of repair parts, complicated processes, etc., and achieve reduced energy consumption, strong oxidation resistance, and strong corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

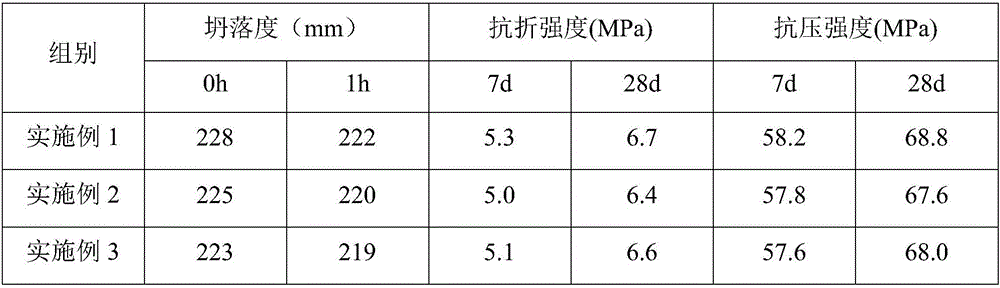

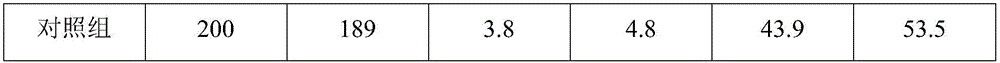

Embodiment 1

[0040] First prepare the gelling aid, nucleating agent and water reducer as follows:

[0041] (1) The preparation method of the gelling aid is specifically:

[0042] a. Mix β-cyclodextrin, silicon dioxide and water at a mass ratio of 1:4.5:2.5, soak for 1.5 hours, and dry the water at 65°C to obtain the third mixture;

[0043] B adds the expanded perlite of 35% of its quality in the third mixture in a, mixes evenly and gets final product;

[0044] (2) The preparation method of the nucleating agent is specifically: grind stone and anhydrite into powder according to the mass ratio of 1:1.5, and the particle size is 0.5mm, then add ferric chloride and copper sulfate and mix evenly, ferric chloride and sulfuric acid The total mass of copper is 1.2% of the total mass of stone and anhydrite;

[0045] (3) The preparation method of water reducing agent is specifically:

[0046] Step 1, the prenol polyoxyethylene ether of 90 parts by weight, the potassium persulfate of 1 part by weigh...

Embodiment 2

[0059] First prepare the gelling aid, nucleating agent and water reducer as follows:

[0060] (1) The preparation method of the gelling aid is specifically:

[0061] a. Mix β-cyclodextrin, silicon dioxide and water at a mass ratio of 1:4:2, soak for 1 hour, and dry the water at 50°C to obtain the third mixture;

[0062] B adds 30% expanded perlite of its quality to the third mixture in a, mixes evenly and gets final product;

[0063] (2) The preparation method of the nucleating agent is as follows: grind stone and anhydrite into powder according to the mass ratio of 1:1, and the particle size is 0.075mm, then add ferric chloride and copper sulfate and mix evenly, ferric chloride and sulfuric acid The total mass of copper is 1% of the total mass of stone and anhydrite;

[0064] (3) The preparation method of water reducing agent is specifically:

[0065] Step 1, the prenol polyoxyethylene ether of 85 parts by weight, the potassium persulfate of 0.8 parts by weight, the diisop...

Embodiment 3

[0078] First prepare the gelling aid, nucleating agent and water reducer as follows:

[0079] (1) The preparation method of the gelling aid is specifically:

[0080] a. Mix β-cyclodextrin, silicon dioxide and water at a mass ratio of 1:5:3, soak for 2 hours, and dry the water at 80°C to obtain the third mixture;

[0081] B adds the expanded perlite of 40% of its quality in the third mixture in a, mixes evenly and gets final product;

[0082] (2) The preparation method of the nucleating agent is as follows: grind stone and anhydrite into powder according to the mass ratio of 1:2, and the particle size is 1.25mm, then add ferric chloride and copper sulfate and mix evenly, ferric chloride and sulfuric acid The total mass of copper is 1.5% of the total mass of stone and anhydrite;

[0083] (3) The preparation method of water reducing agent is specifically:

[0084] Step 1, the prenol polyoxyethylene ether of 95 parts by weight, the potassium persulfate of 1.5 parts by weight, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com