Method and device for preparing special fertilizer for oil tea

A special fertilizer and camellia oleifera technology, applied in the fields of application, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of unsuitable promotion of production, single nutrient elements, and difficulty in large-scale application, and achieve the effect of novel structure, sufficient nutrition, and hardness that is not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

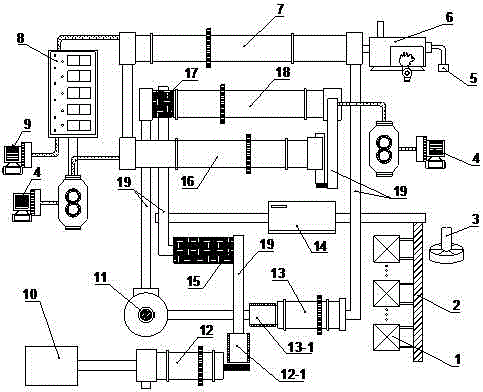

[0052] (1) Preparation method: see figure 1 , including the following steps:

[0053] (a) Material preparation and measurement: take the required raw materials separately and put them into at least two weighing buckets (1) with apron-shaped conveyor belts for weighing and measuring;

[0054] (b) Stirring and mixing: the raw materials that have been weighed in step (a) pass through the automatic water spray devices on both sides of the first conveyor belt (2) in sequence, and then the at least two weighing hoppers (1) are fed separately Put the raw materials into the mixer (3) in sequence, and mix the raw materials evenly in the mixer to obtain the mixed raw materials, wherein the natural moisture of the raw materials is kept at 5%-7% after passing through the automatic water spray device;

[0055] (c) Primary granulation: the mixed raw material obtained in step (b) passes through the second bag filter (14) and crusher (11) in sequence, the dust of the mixed raw material is re...

Embodiment 2

[0068] (1) Preparation method: see figure 1 , including the following steps:

[0069] (a) Material preparation and measurement: take the required raw materials separately and put them into at least two weighing buckets (1) with apron-shaped conveyor belts for weighing and measuring;

[0070] (b) Stirring and mixing: the raw materials that have been weighed in step (a) pass through the automatic water spray devices on both sides of the first conveyor belt (2) in sequence, and then the at least two weighing hoppers (1) are fed separately Put the raw materials into the mixer (3) one by one, and mix the raw materials evenly in the mixer to obtain the mixed raw materials, wherein the natural moisture of the raw materials is kept at 6%-8% after passing through the automatic water spray device;

[0071] (c) Primary granulation: the mixed raw material obtained in step (b) passes through the second bag filter (14) and crusher (11) in sequence, the dust of the mixed raw material is rem...

Embodiment 3

[0077] (1) Preparation method: see figure 1 , including the following steps

[0078] (a) Material preparation and measurement: take the required raw materials separately and put them into at least two weighing buckets (1) with apron-shaped conveyor belts for weighing and measuring;

[0079] (b) Stirring and mixing: the raw materials that have been weighed in step (a) pass through the automatic water spray devices on both sides of the first conveyor belt (2) in sequence, and then the at least two weighing hoppers (1) are fed separately Put the raw materials into the mixer (3) in sequence, and mix the raw materials evenly in the mixer to obtain the mixed raw materials, wherein the natural moisture of the raw materials is kept at 5%-7% after passing through the automatic water spray device;

[0080](c) Primary granulation: the mixed raw material obtained in step (b) passes through the second bag filter (14) and crusher (11) in sequence, the dust of the mixed raw material is remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com