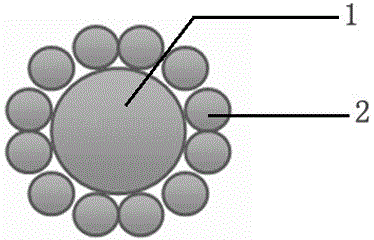

Core-shell structure hybrid sol with photocatalysis characteristic, and preparation and application thereof

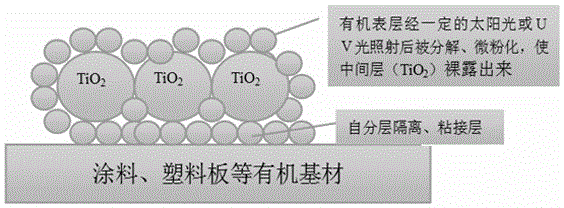

A core-shell structure, photocatalytic technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, biocide-containing paints, etc., can solve practical and economic defects, high cost, energy waste and other problems, to achieve the effects of high crystallinity, simple reaction conditions and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of aqueous titanium peroxide precursor (PTC):

[0038] 1) Put 40g of TiCl in an ice-water bath 4 Drop into 1000mL of vigorously stirred pure water at a rate of 1 drop / s to prepare 0.2mol / L of TiCl 4 solution;

[0039] 2) Adjust the pH value of the solution to 8 with ammonia water with a mass fraction of 2%, to obtain a precipitate of orthotitanic acid, and wash the precipitate with deionized water 10 times;

[0040] 3) The precipitate was dispersed in 200 mL of hydrogen peroxide solution with a mass concentration of 10% to prepare an aqueous titanium peroxide precursor (PTC).

[0041] 2. Preparation of silicone adhesive precursor: add 25mL ethyl silicate and 1.5mL nitric acid into 250mL methanol solution, disperse with 600W ultrasonic wave for 30min, and obtain a methanol solution containing ethyl silicate with pH=1, which is Silicone adhesive precursor.

[0042] 3. Preparation of core-shell structure hybrid sol: Take 100mL of the prepared silicone ad...

Embodiment 2

[0046] 1. Nano-TiO 2 Sol preparation:

[0047] 1) Add 0.1mol of TiOSO to the 4 Drop into 1000mL of vigorously stirred pure water at a rate of 1 drop / s to prepare 0.1mol / L TiOSO 4 solution;

[0048] 2) Adjust the pH value of the solution to 8 with ammonia water to obtain a precipitate of orthotitanic acid, and wash the precipitate with deionized water 10 times;

[0049] 3) Disperse the precipitate in 400mL hydrogen peroxide solution with a mass concentration of 30% to prepare an aqueous titanium peroxide (PTC) solution;

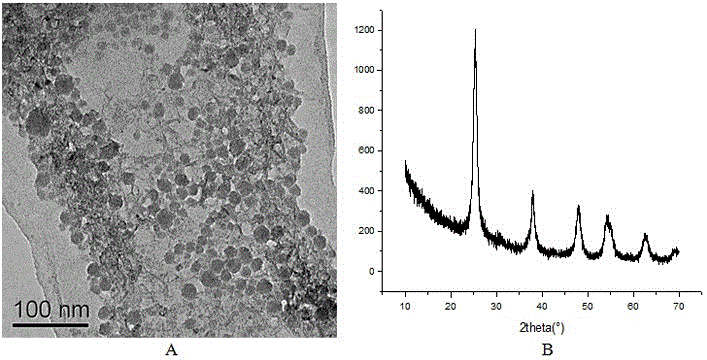

[0050] 4) Dilute the above-prepared PTC solution with water to 1000mL, raise the temperature to 80°C and keep it under reflux for 3h to prepare nano-TiO 2 The resulting sol contains a large number of incompletely reacted titanium hydroxyl groups (Ti-O-H), which makes the sol negatively charged.

[0051] 2. Preparation of core-shell structure hybrid sol: take the nano-TiO prepared above 2 Sol 200mL, add 5mL inorganic nano-SiO with a solid content of 20% ...

Embodiment 3

[0054] 1. Nano-TiO 2 The preparation of the sol is the same as in Example 2.

[0055] 2. Preparation of nano-organic microemulsion intermediates:

[0056] 1) The reaction monomers methyl methacrylate (MMA), butyl acrylate (BA), acrylic acid (AA), emulsifier OP-10 and pure water are prepared according to the mass ratio of 3:2:1.5:0.2:10. Emulsified mixture 600mL;

[0057] 2) Add 200mL of the above-mentioned pre-emulsified mixture to a four-neck flask equipped with a stirrer, reflux condenser, and thermometer, then add a pH adjustment buffer (sodium bicarbonate with a mass fraction of 5%) to adjust the pH to 6, and mechanically stir Disperse for 1 hour, then raise the temperature to 75°C, then add 20 mL of primer (aqueous potassium persulfate solution with a mass fraction of 5%), keep the reaction for half an hour to form seeds, then raise the temperature to 80°C, and then continuously drop the remaining pre-emulsified Mixture, and then synchronously add 40mL initiator dropwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com