Zeolite molecular sieve-heat conducting framework composite adsorbent and preparation method

A zeolite molecular sieve and composite adsorption technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem of inability to overcome the microscopic heat transfer capacity of zeolite molecular sieves, the ineffective separation of force desorption capabilities, and the inability to effectively adsorb VOCs molecules. and other issues, to achieve the effect of increasing thermal conductivity and mass transfer performance, good crystallinity and purity, and reducing the decline in zeolite performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

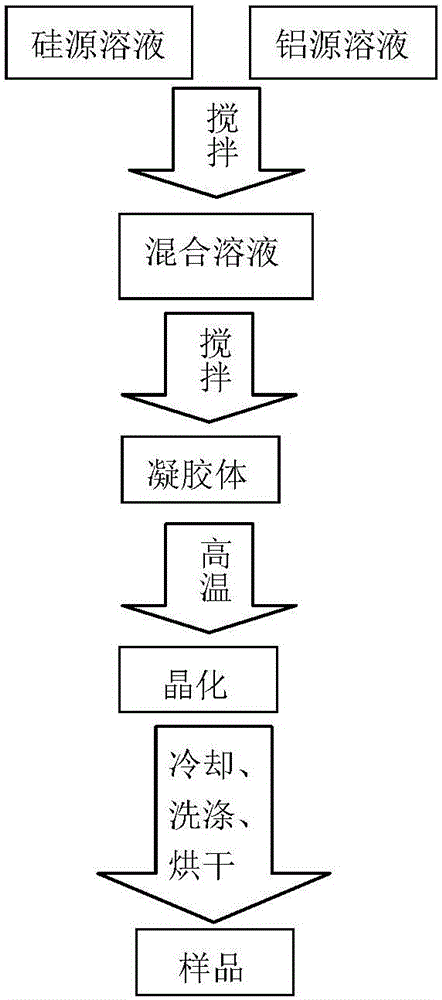

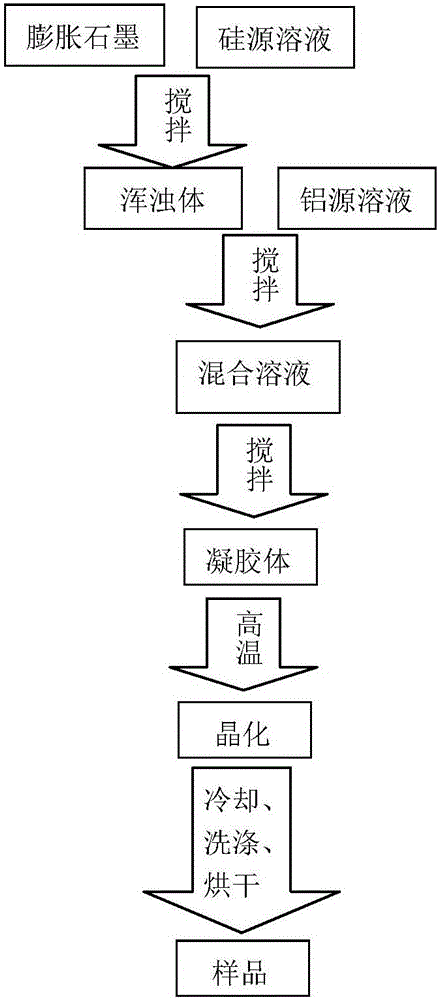

Embodiment 1

[0045] First weigh 0.375g of sodium hydroxide and 3.21g of sodium chloride, dissolve them in 20ml of deionized water, then add 1.84g of sodium silicate, and stir them into a uniform colloid with a magnetic stirrer to obtain A solution; then weigh 1.71g Aluminum sulfate, put in a 100ml beaker, add 10ml of deionized water, stir to dissolve, then add 0.5g of expanded graphite, stir until the expanded graphite is completely mixed with the solution to form a cloudy solution of B; add solution A dropwise to the stirring B In the turbid liquid, stir for 10 minutes until it is uniform, then add 1.36ml of ethylenediamine, stir evenly, and test the pH value of the mixed colloid with pH test paper. Put the gelled mixture into a polytetrafluoroethylene kettle jacket, then put it into a stainless steel reaction kettle, tighten the lid of the kettle, put it in an electric thermostat, age at 100°C for 24 hours, crystallize at 160°C for 30 hours, take it out . After cooling to room temperatu...

Embodiment 2

[0048] First weigh 0.375g of sodium hydroxide and 3.21g of sodium chloride, dissolve them in 20ml of deionized water, then add 1.84g of sodium silicate, and stir them into a uniform colloid with a magnetic stirrer to obtain A solution; then weigh 1.71g Aluminum sulfate, put in a 100ml beaker, add 10ml of deionized water, stir to dissolve; add solution A dropwise to solution B which is being stirred, stir for 10min until uniform, then add 1.36ml of ethylenediamine, stir evenly to form a gel solution, add 0.5g copper powder in the process of continuing to stir, stir evenly, and test the pH value of the mixed colloid with PH test paper. Put the gelled mixture into a polytetrafluoroethylene kettle jacket, and then put it in an electric thermostat at 100°C to stir and heat to evaporate the water. After the belt is completely evaporated, put the gel into a vacuum sintering furnace for sintering at 700°C Sinter for 15 minutes, cool to ambient temperature and take out. A zeolite mole...

Embodiment 3

[0051] First weigh 0.375g of sodium hydroxide and 3.21g of sodium chloride, dissolve them in 20ml of deionized water, then add 1.71g of aluminum sulfate, stir with a magnetic stirrer to form a uniform colloid, and prepare A solution; then weigh 1.84g of silicon Sodium acid, take 1.36ml of ethylenediamine, put it in a 100ml beaker, add 10ml of deionized water, stir to dissolve, then add 0.5g of expanded graphite, and stir until the expanded graphite is completely mixed with the solution to form a cloudy solution of B; Add it dropwise to the stirring B turbid solution, stir evenly, and test the pH value of the mixed colloid with pH test paper. Put the gelled mixture into a polytetrafluoroethylene kettle jacket, then put it into a stainless steel reaction kettle, tighten the lid of the kettle, put it in an electric thermostat, age at 100°C for 24 hours, crystallize at 160°C for 30 hours, take it out . After cooling to room temperature with water, the product is washed and filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com