Carbon quantum dots/eu3+/mesoporous alumina composite luminescent material and its preparation and application

A technology of mesoporous alumina and carbon quantum dots, applied in luminescent materials, thermometers with physical/chemical changes, measuring heat, etc., can solve the problems of no luminescent carbon quantum dots and mesoporous alumina composite optical materials, and achieve Ease of industrial production, short time consumption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

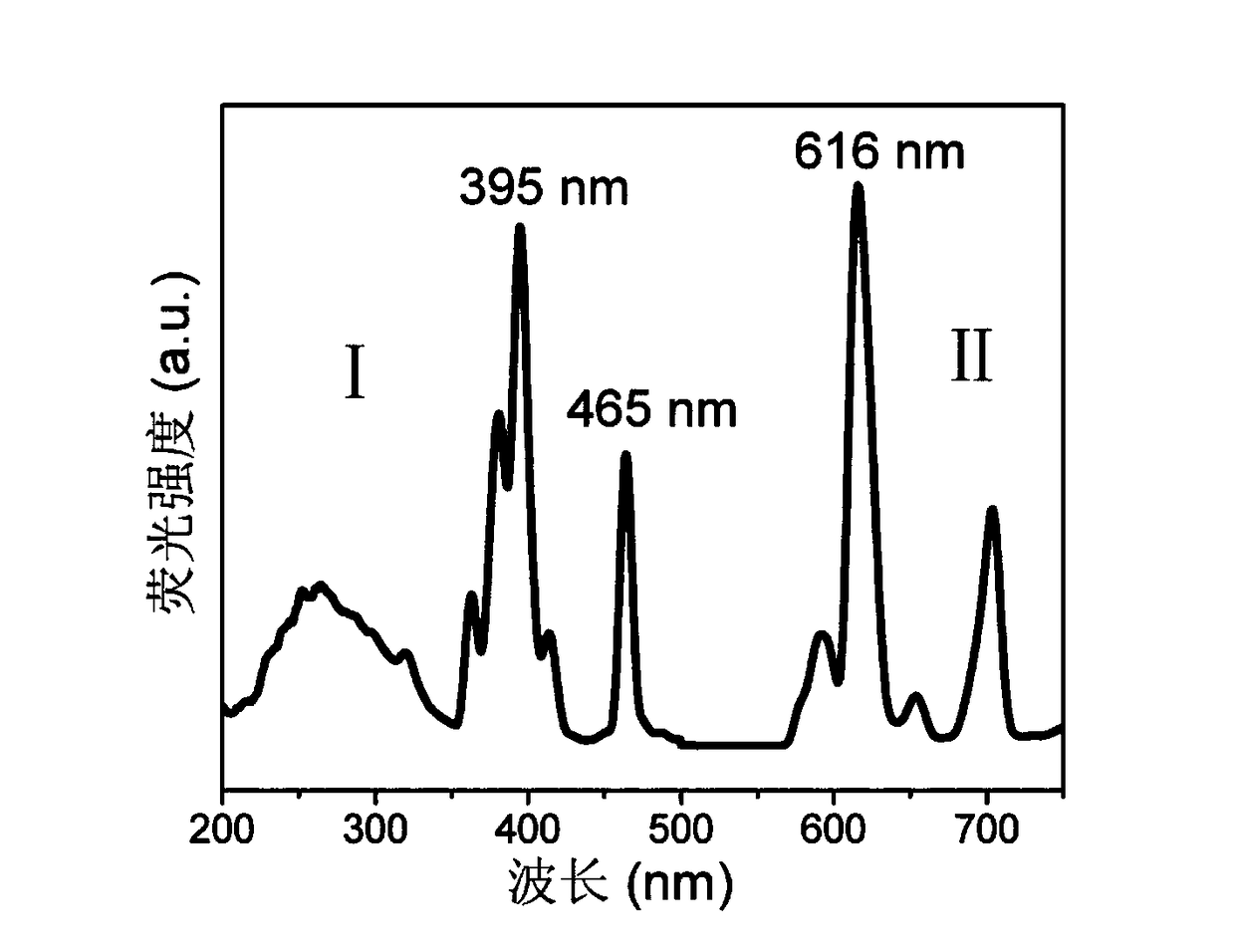

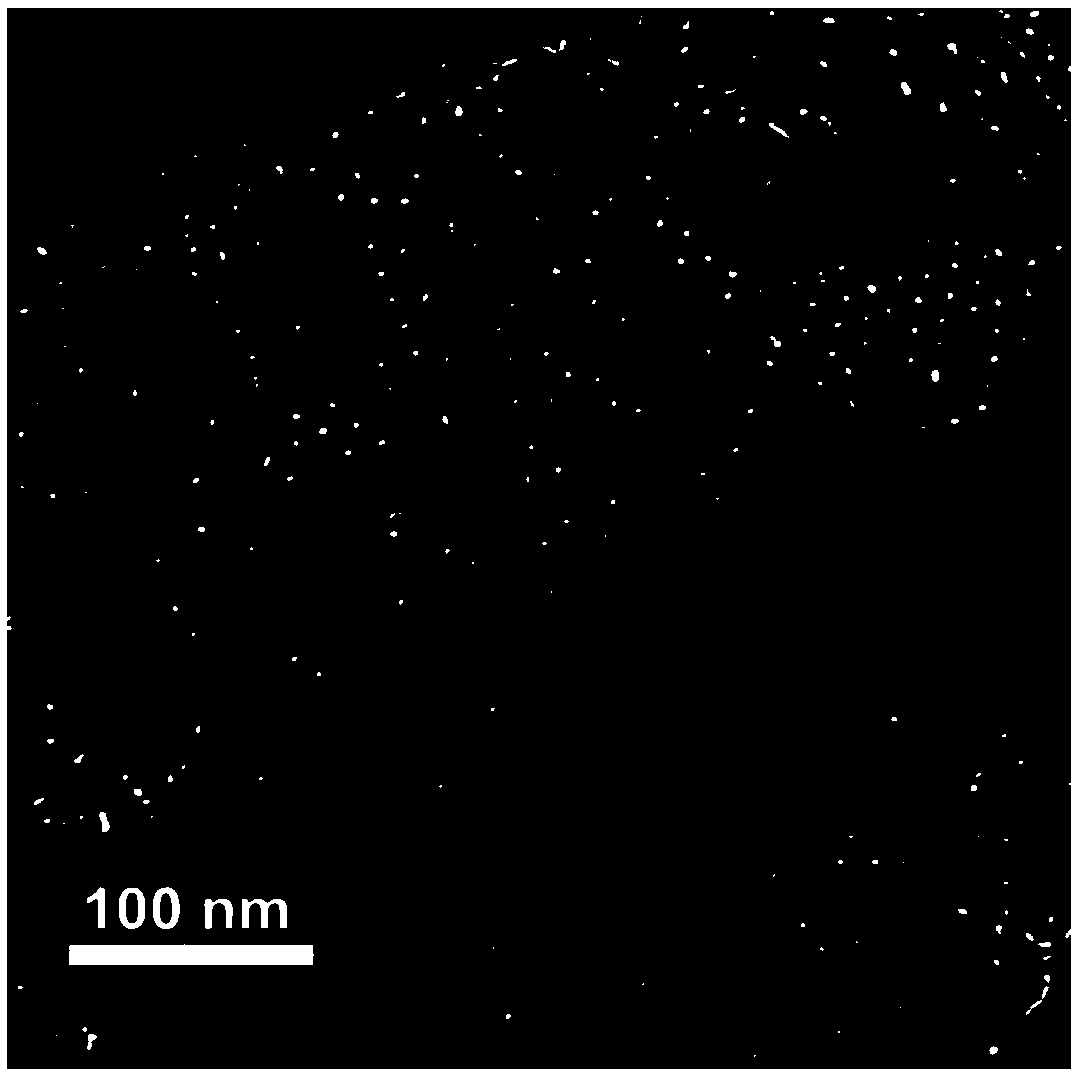

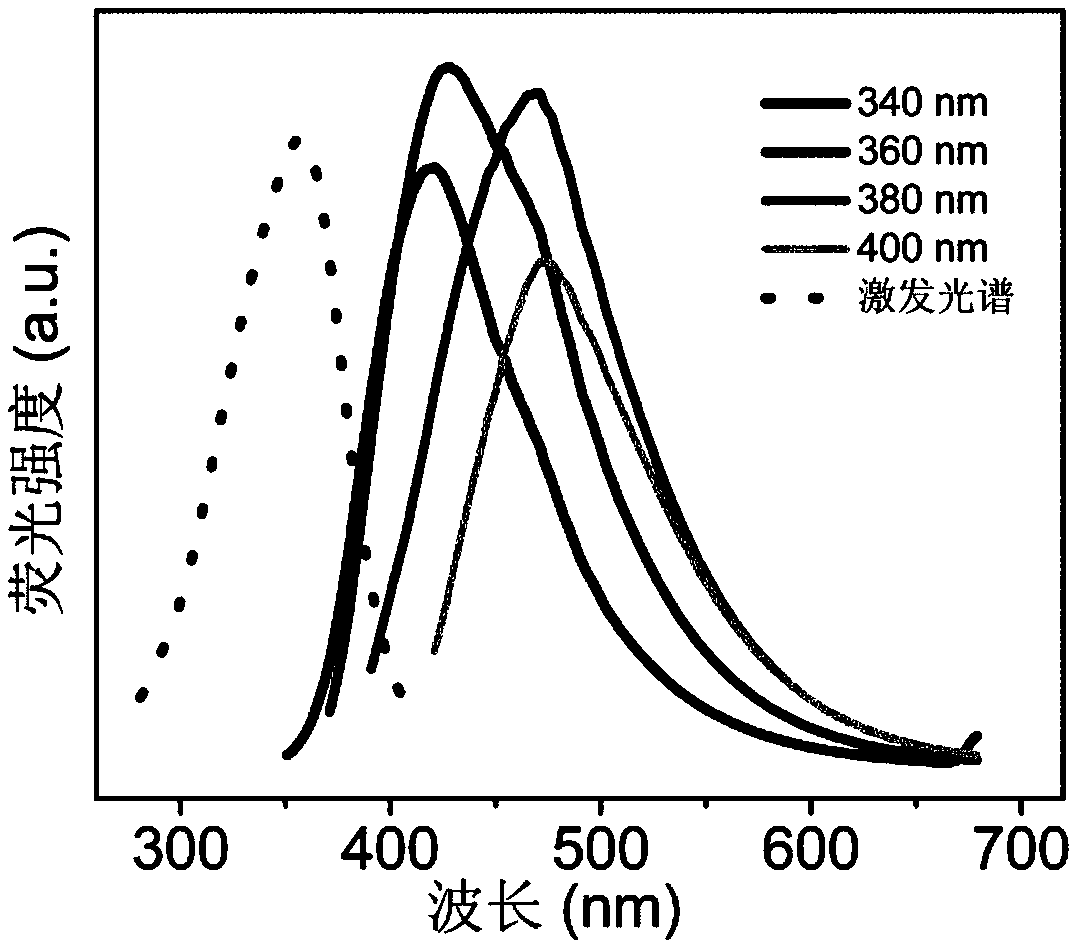

[0049] Embodiment 1: fluorescent carbon quantum dots / Eu 3+ / Preparation of Mesoporous Alumina Composite Luminescent Materials

[0050] (1) Preparation of mesoporous alumina doped with trivalent europium: 1.0g P123 as template, then add 0.5g anhydrous citric acid, 15mL absolute ethanol as solvent, stir to obtain a transparent solution, add 1.0mL hydrochloric acid and 1.5 mL glacial acetic acid, add 10mmol aluminum isopropoxide as aluminum source, stir thoroughly for 8h, add 2mL 0.5mol / L Eu(NO 3 ) 3 , continue to stir to obtain a white milky shape, transfer to a 40°C water bath, continue to stir for 4h, transfer to a 60°C oven to dry for 48h, and finally perform high-temperature calcination on the sample. Keep the temperature at 400°C for 240 minutes, then raise the temperature to 800°C at a rate of 10°C / min, keep the temperature for 120 minutes, and then grind to obtain white phosphor. The method is a sol-gel method to prepare the matrix material;

[0051] (2) Preparation ...

Embodiment 2

[0056] Embodiment 2: fluorescent carbon quantum dots / Eu 3+ / Preparation of Mesoporous Alumina Composite Luminescent Materials

[0057] (1) Preparation of mesoporous alumina doped with trivalent europium: refer to Example 1;

[0058] (2) Preparation of fluorescent carbon quantum dots: Dry fresh dried banana peels in an oven at 60°C for 10 hours, take 1.0g of dried banana peels, and 3mL 30%H 2 o 2 Carry out hydrothermal reaction with 30mL deionized water at 180°C, set the time for 4h to obtain a brownish-yellow turbid liquid, filter, centrifuge for 10min at a speed of 12000rpm / min, and dialyze (1000D) to obtain a brownish-yellow liquid, freeze-dry to obtain solid fluorescent carbon quantum dots ;

[0059] (3) Take the solid fluorescent carbon quantum dot prepared in step (2) and mix 100mL deionized water to obtain a carbon dot solution of 0.01g / mL, and then add the carbon dot solution to 1g of the doped three prepared in step (1). Europium-valent mesoporous alumina, stirred...

Embodiment 3

[0061] Embodiment 3: fluorescent carbon quantum dots / Eu 3+ / Preparation of Mesoporous Alumina Composite Luminescent Materials

[0062] (1) Preparation of mesoporous alumina doped with trivalent europium: refer to Example 1;

[0063] (2) Preparation of fluorescent carbon quantum dots: 0.9g p-phenylenediamine and 90mL ethanol, conduct solvothermal reaction in a reaction kettle, set the reaction temperature at 200°C, take 10h, cool down to room temperature, and obtain orange, dark red, gray multilayer The suspension was purified by column using dichloromethane and methanol, followed by continuous plate spotting, washing, filtering, dialysis (1000D), and freeze-drying to obtain solid fluorescent carbon quantum dots.

[0064] (3) Take the solid fluorescent carbon quantum dot prepared in step (2) and mix 100mL deionized water to obtain a carbon dot solution of 0.01g / mL, and then add the carbon dot solution to 1g of the doped three prepared in step (1). Europium-valent mesoporous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com