A kind of preparation method of polycondensation type graphene/polyimide composite adhesive

A composite adhesive and graphene technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as uneven dispersion, achieve uniform composition, expand application prospects, and improve solubility and dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

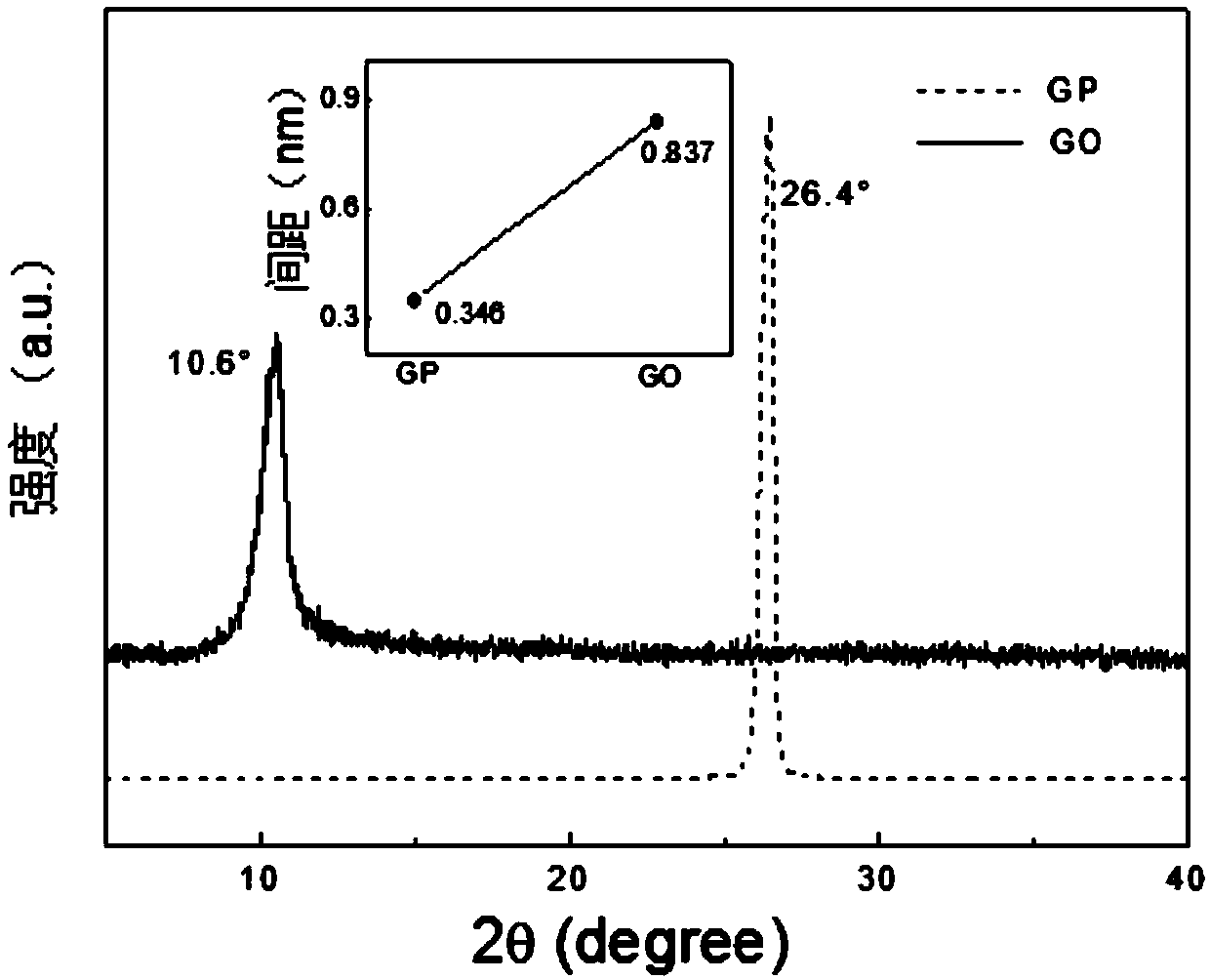

[0042] (1) Oxidation of graphite powder:

[0043] 85ml of concentrated H with a mass fraction of 98% 2 SO 4 solution and 15ml mass fraction of 80% concentrated H 3 PO 4 The solution was successively added into a round-bottomed flask with a volume of 250ml, mechanically stirred and mixed with a stirrer at a speed of 300rpm for 5min, and 1g of graphite powder (flake graphite, particle size≤30μm, proportion≥95%) was added to the resulting mixed acid solution , continue to stir at a speed of 300rpm until the system is evenly mixed, and 5g KMnO 4 Slowly add a small amount to the above solution several times, and stir for 30 minutes at a rotation speed of 350 rpm; under the condition of oil bath temperature control, stir and react at 40°C for 2h, then raise the temperature to 90°C and stir for 1.5h. Subsequently, the excess KMnO was reduced by adding a dilute hydrogen peroxide solution with a mass fraction of 4.5% 4 , Obtain graphite oxide mixed solution; The preparation method...

Embodiment 2

[0056] (1) Oxidation of graphite powder:

[0057] 90ml of concentrated H with a mass fraction of 98% 2 SO 4 solution and 10ml mass fraction is 81% concentrated H 3 PO 4 The solution was successively added into a round bottom flask with a volume of 250ml, mechanically stirred and mixed with a stirrer at a speed of 310rpm for 5min, and 1g of graphite powder (flake graphite, particle size≤30μm, proportion≥95%) was added to the resulting mixed acid solution , continue to stir at a speed of 300rpm until the system is evenly mixed, and 6g KMnO 4 Slowly add small amounts to the above solution several times, and stir at 350 rpm for 25 minutes; under oil bath temperature control, stir and react at 40°C for 2h, then raise the temperature to 90°C and stir for 1.5h. Subsequently, the excess KMnO was reduced by adding a dilute hydrogen peroxide solution with a mass fraction of 4.5% 4 , Obtain graphite oxide mixed solution; The preparation method of described hydrogen peroxide is that ...

Embodiment 3

[0069] (1) Oxidation of graphite powder:

[0070] 91ml of concentrated H with a mass fraction of 98% 2 SO 4 solution and 9ml mass fraction of 82% concentrated H 3 PO 4 The solution is successively added into a round bottom flask with a volume of 250ml, mechanically stirred and mixed for 5min at 310rpm with a stirrer, and 1.5g of graphite powder (flaky graphite, particle size≤30 μm, accounting for≥95% ), continue to stir at 300rpm until the system is evenly mixed, and 7g KMnO 4 Slowly add small amounts to the above solution several times, and stir at 350 rpm for 25 minutes; under oil bath temperature control, stir and react at 40°C for 2h, then raise the temperature to 90°C and stir for 1.5h. Subsequently, the excess KMnO was reduced by dropping a 3% dilute hydrogen peroxide solution 4 , Obtain graphite oxide mixed solution; The preparation method of described hydrogen peroxide is: in the beaker that fills 100ml deionized water, add 10ml mass fraction and be 30% H 2 o 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com