3D printing membrane for absorbing ether organic compounds and preparation method thereof

A technology for organic matter and printing membranes, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of difficult absorption and treatment of VOCs, secondary pollution, high processing costs, etc., and achieve low cost, good shock resistance and excellent preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

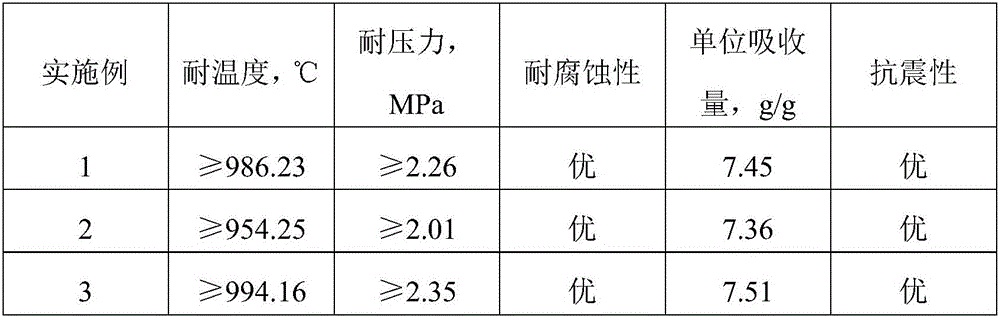

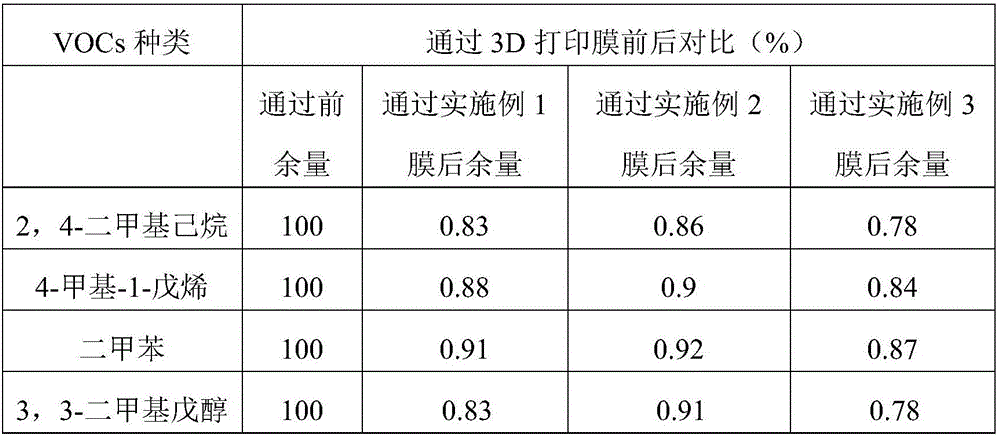

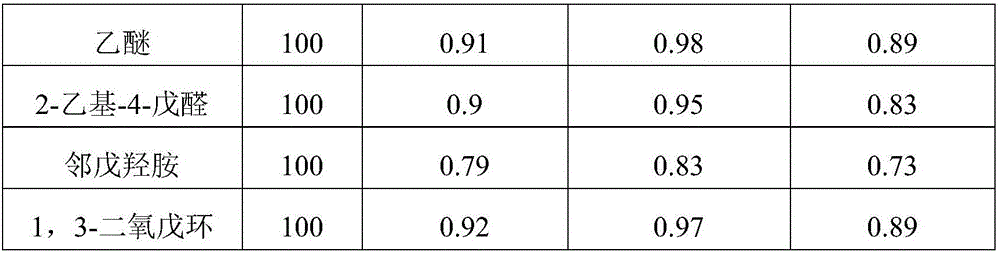

Examples

preparation example Construction

[0036] The preparation method of the 3D printing film absorbing organic substances such as ethers, comprises the following steps:

[0037] S1: Soak sepiolite, hydrotalcite, calcium silicate, activated carbon, kaolinite, and zeolite in deionized water to wash off the attached pollutants, then dry them until the water content is ≤ 2%, and then dry the dried Sepiolite, hydrotalcite, calcium silicate, activated carbon, kaolinite, zeolite, and calcium oxide, anhydrous calcium chloride, anhydrous copper sulfate, carbon fiber, glass fiber are placed in the nano pulverizer, at a speed of 1000- Grinding at 1200r / min for 1-1.5h and passing through a sieve to obtain mixture A;

[0038] S2: Stir the mixture A, isopropyl titanate, methyl isobutyl ketone, graphene, initiator, and toughening agent prepared in step S1 at a temperature of 220-260°C and a rotation speed of 400-600r / min After 2-3 hours, put it into a nano pulverizer to pulverize to obtain the mixture B;

[0039] S3: mix the mi...

Embodiment 1

[0043] A 3D printing film for absorbing ethers and other organic substances, including the following raw materials in parts by weight: 92 parts of sepiolite, 50 parts of hydrotalcite, 26 parts of calcium silicate, 25 parts of activated carbon, 16 parts of kaolinite, zeolite 14 parts, 8 parts of calcium oxide, 12 parts of anhydrous calcium chloride, 8 parts of anhydrous copper sulfate, 16 parts of carbon fiber, 6 parts of isopropyl titanate, 8 parts of methyl isobutyl ketone, 5 parts of glass fiber, graphite 1.8 parts of alkenes, 0.5 parts of initiators, 2 parts of toughening agents, 1.3 parts of coagulants, and 0.8 parts of stabilizers.

[0044] The initiator is dicyclohexyl peroxydicarbonate.

[0045] The toughening agent is ethylene-propylene rubber.

[0046] The coagulant is polyaluminum chloride.

[0047] The stabilizer is an organotin stabilizer.

[0048] The preparation method of the 3D printing film absorbing organic substances such as ethers, comprises the following...

Embodiment 2

[0054] A 3D printing film for absorbing organic substances such as ethers, including the following raw materials in parts by weight: 65 parts of sepiolite, 36 parts of hydrotalcite, 14 parts of calcium silicate, 17 parts of activated carbon, 11 parts of kaolinite, zeolite 10 parts, 6 parts of calcium oxide, 8 parts of anhydrous calcium chloride, 6 parts of anhydrous copper sulfate, 13 parts of carbon fiber, 4 parts of isopropyl titanate, 5 parts of methyl isobutyl ketone, 4 parts of glass fiber, graphite 1.2 parts of alkenes, 0.4 parts of initiators, 1.4 parts of toughening agents, 1.1 parts of coagulants, and 0.6 parts of stabilizers.

[0055] The initiator is dicyclohexyl peroxydicarbonate.

[0056] The toughening agent is ethylene-propylene rubber.

[0057] The coagulant is polyaluminum chloride.

[0058] The stabilizer is an organotin stabilizer.

[0059] The preparation method of the 3D printing film absorbing organic substances such as ethers, comprises the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com