Iron oxide loaded biomass carbonized microspheres and preparation method and application thereof

A technology of carbonizing microspheres and biomass, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of low comprehensive utilization rate, complicated preparation process, poor adsorption performance, etc., and achieve low comprehensive utilization rate , Stable physical and chemical properties, and improved adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

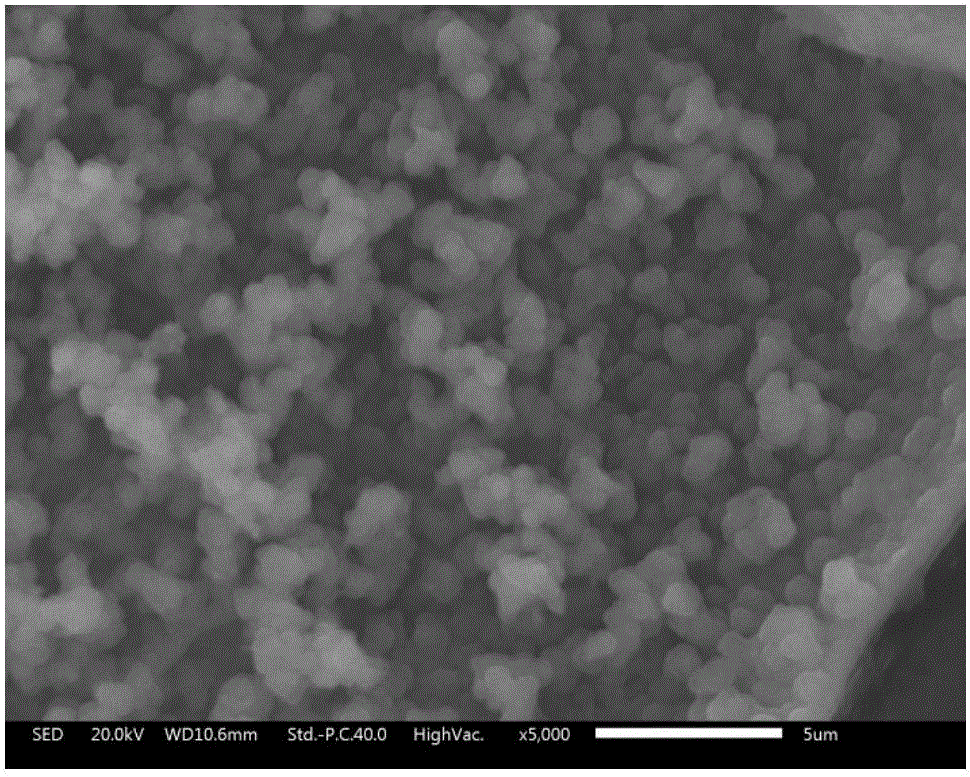

Embodiment 1

[0027] After boiling 80mL of 0.001mol / L CTMAB, add 20mL of 0.025mol / L ferric sulfate solution dropwise, and after cooling, adjust the pH to 9.0 with sodium hydroxide solution. Shred the coconut shells and soak them in liquid nitrogen, then immediately transfer the frozen coconut shells to a mortar and grind them into powder quickly, pass through a 100-mesh sieve, add 1g of coconut shells into the solution, and mix thoroughly with magnetic stirring. The solution was heated and stirred to evaporate to a total volume of about 20 mL, and dried in an oven at 60°C for 24 hours. Place the dried sample in 10 mL of 0.005 mol / L zinc acetate solution, hydrothermal carbonization final temperature is 200°C, time is 8 hours, rinse the product with water and ethanol after cooling, and then dry it in an oven for 24 hours, namely Biomass carbonized microspheres loaded with iron oxide are obtained.

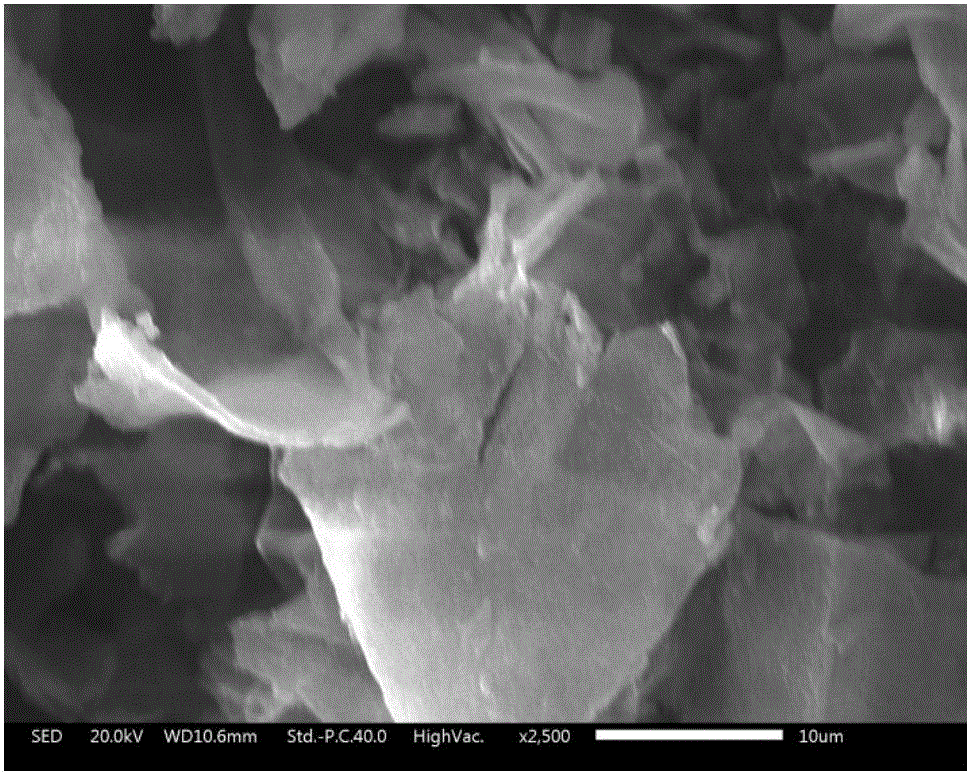

Embodiment 2

[0029] After boiling 80mL of 0.001mol / L CTMAB, add 20mL of 0.05mol / L ferric nitrate solution, and after cooling, adjust the pH to 9.0 with sodium hydroxide solution. Shred the coconut shells and soak them in liquid nitrogen, then immediately transfer the frozen coconut shells to a mortar and grind them into powder quickly, pass through a 100-mesh sieve, add 1g of coconut shells into the solution, and mix thoroughly with magnetic stirring. The solution was heated and stirred to evaporate to a total volume of about 20 mL, and dried in an oven at 60°C for 24 hours. Place the dried sample in 10 mL of 0.005 mol / L zinc acetate solution, hydrothermal carbonization final temperature is 200°C, time is 8 hours, rinse the product with water and ethanol after cooling, and then dry it in an oven for 24 hours, namely Biomass carbonized microspheres loaded with iron oxide are obtained.

Embodiment 3

[0031] Under room temperature condition, be that 11.58, 26.53, 30.29 and 40.96mg / L leaded solution are carried out adsorption reaction with the material that 0.01g embodiment 1 prepares to 20mL concentration respectively, and wherein reaction time is 12 hours, the lead ion concentration in the filtrate is charged with electricity The inductively coupled plasma emission spectrometer measures that the removal rate of the material to lead ions reaches more than 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com