Method for synthesizing plasma composite photocatalyst

A plasma and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low catalytic activity, and achieve the effect of good dispersion and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Ag / AgCl / AgBi(MoO 4 ) 2 Preparation of plasmonic photocatalyst

[0019] 1mmol of silver nitrate and 1mmol of bismuth nitrate were ultrasonically stirred and uniformly dispersed in 5mL of deionized water, and an aqueous solution containing 2mmol of sodium molybdate was added dropwise during the stirring process; microwave hydrothermal reaction was carried out at 160°C for 5 minutes in a microwave digestion apparatus with a power of 200W ; The product obtained is washed alternately three times with absolute ethanol and deionized water to obtain nanometer silver bismuth molybdate; the AgBi(MoO 4 ) 2 Ultrasonic dispersion in ethylene glycol, adding different amounts of potassium chloride, fully stirred for 4 hours, to obtain AgCl / AgBi (MoO 4 ) 2 The obtained sample is centrifuged and washed to remove residual ethylene glycol; the obtained sample is dispersed in deionized water and irradiated by a xenon lamp for 30 minutes. After the reaction is completed, the p...

Embodiment 2

[0020] The characterization analysis of the prepared plasma photocatalyst of embodiment 2

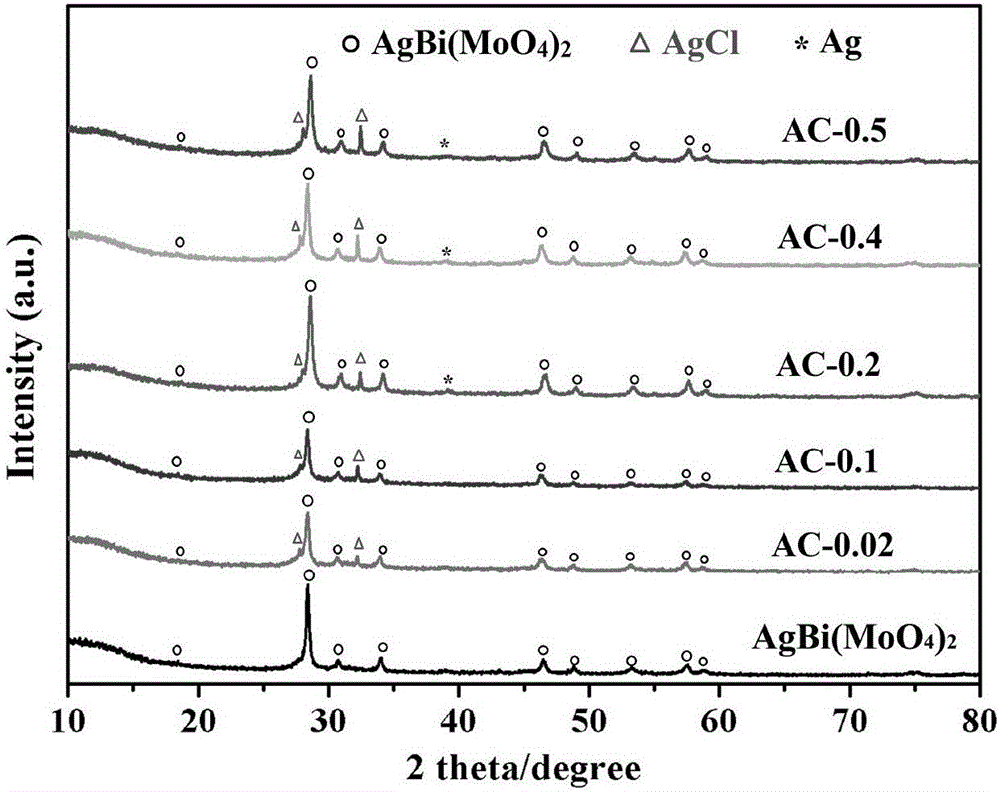

[0021] Such as figure 1 As shown, it can be seen from the figure that the compounded sample has Ag, AgCl, AgBi(MoO 4 ) 2 The characteristic peaks indicate that we have successfully prepared Ag / AgCl / AgBi(MoO 4 ) 2 plasmonic photocatalyst.

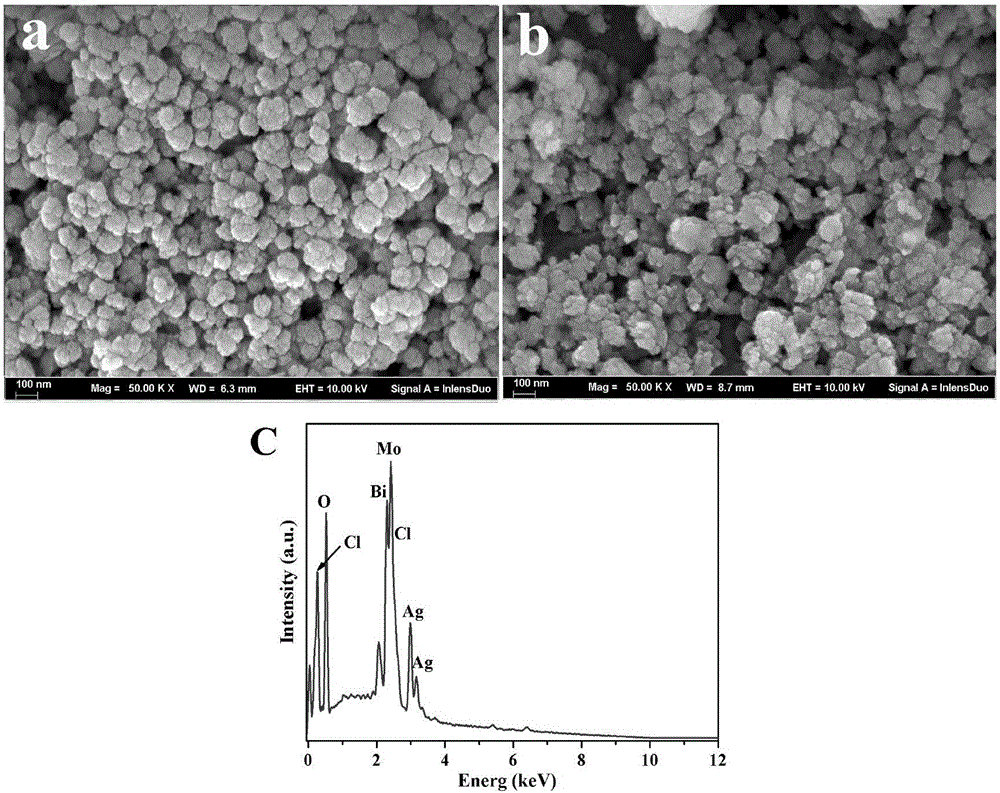

[0022] Such as figure 2 As shown in (A), pure AgBi(MoO 4 ) 2 It is a nanoparticle, assembled from nanoparticles with a size of 10-20nm, and the size is 100nm. In (B), it can be seen that AgBi(MoO 4 ) 2 The surface of the nanoparticles becomes rough due to the influence of Ag / AgCl, and the shape is irregular. The size of the nanoparticles is 120nm. The spectrum in (C) shows the presence of Ag, Mo, Bi, Cl, and oxygen elements.

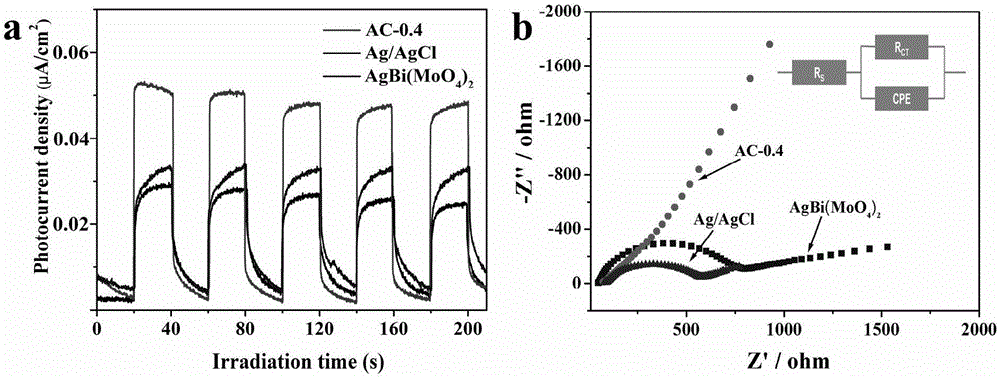

[0023] Such as image 3 As shown, (a) can clearly see that Ag / AgCl / AgBi(MoO 4 ) 2 The photocurrent intensity after illumination is significantly higher than that of Ag / AgCl and AgBi(MoO 4 ) 2 samples, showing the ...

Embodiment 3

[0024] Example 3 Ag / AgCl / AgBi(MoO 4 ) 2 Visible light catalytic activity experiments of plasmonic photocatalysts

[0025] (1) Prepare a tetracycline hydrochloride solution with a concentration of 10 mg / L, and place the prepared solution in a dark place.

[0026] (2) Weigh Ag / AgCl / AgBi(MoO 4 ) 2 Plasma photocatalyst 100mg (when AgBi(MoO 4 ) 2 The mass is 200mg, and the KCl moles are 0.02, 0.1, 0.2, 0.4 and 0.5mmol respectively. 1:15, 1:3, 2:3, 4:3 and 5:3), respectively placed in the photocatalytic reactor, add 100mL of the target degradation solution prepared in step (1), stir magnetically for 30min and wait for the photocatalytic reaction After the catalyst is evenly dispersed, turn on the water source and the light source to carry out the photocatalytic degradation experiment.

[0027] (3) Draw the photocatalytic degradation solution in the reactor every 10 minutes, centrifuge and use it for the measurement of ultraviolet-visible absorbance.

[0028] (4) by Figure 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com